A Lean TPS Approach to Continuous Improvement

Kaizen is not always a breakthrough idea. In the Toyota Production System, most improvements are small and practical. They remove waste, simplify daily work, and strengthen stability. These steady, structured improvements are what transform culture over time.

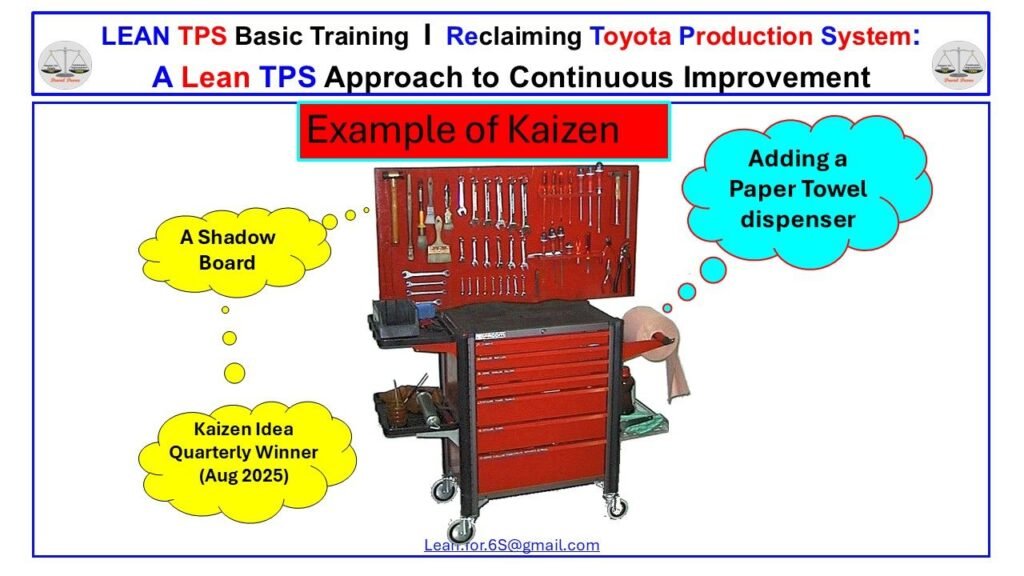

The example shown here demonstrates how visibility and access improve flow in everyday operations.

A simple workstation was redesigned using two small Kaizen ideas that made a lasting impact.

1. A Shadow Board for Tools

When tools are stored in drawers, time is lost opening, searching, and closing them. This breaks rhythm, interrupts focus, and hides problems.

By mounting the tools on a shadow board, each item became visible at a glance. Every tool had a defined location, and missing items could be seen immediately.

This small change reduced motion waste, improved availability, and made workplace organization self-sustaining. The shadow board became the standard.

2. Adding a Paper Towel Dispenser

Another small but effective improvement was adding a paper towel dispenser directly to the workstation. Cleanup was faster, motion was reduced, and interruptions were eliminated.

The team that proposed this idea won the Kaizen Idea of the Quarter because it addressed real waste in daily work. It did not require investment or approval meetings. It required observation and structured problem solving.

Why It Matters

This example illustrates what Lean TPS means by “continuous improvement.”

Kaizen is not a separate program or event. It is the daily act of identifying and removing waste to support flow.

At Toyota, Kaizen sits at the foundation of the Lean TPS house alongside Standardized Work and 5S Thinking. Together they create the base that supports the pillars of Just-in-Time and Jidoka. Without this base, the roof of quality, cost, and delivery cannot hold.

Each small improvement builds capability.

A shadow board is not just organization. It is part of takt time and visual control.

A paper towel dispenser is not just convenience. It eliminates motion waste and supports Standardized Work.

Each idea, when done with structure and confirmation, strengthens the system.

Leadership Reflection

True Kaizen is continuous improvement by design.

It is not a set of projects or isolated events. It is the daily learning that develops people and makes improvement sustainable.

The leaders who practice Kaizen Thinking connect every change back to system stability and flow. That connection is what makes Lean TPS different from ordinary efficiency programs.

Kaizen strengthens both the process and the people who improve it.