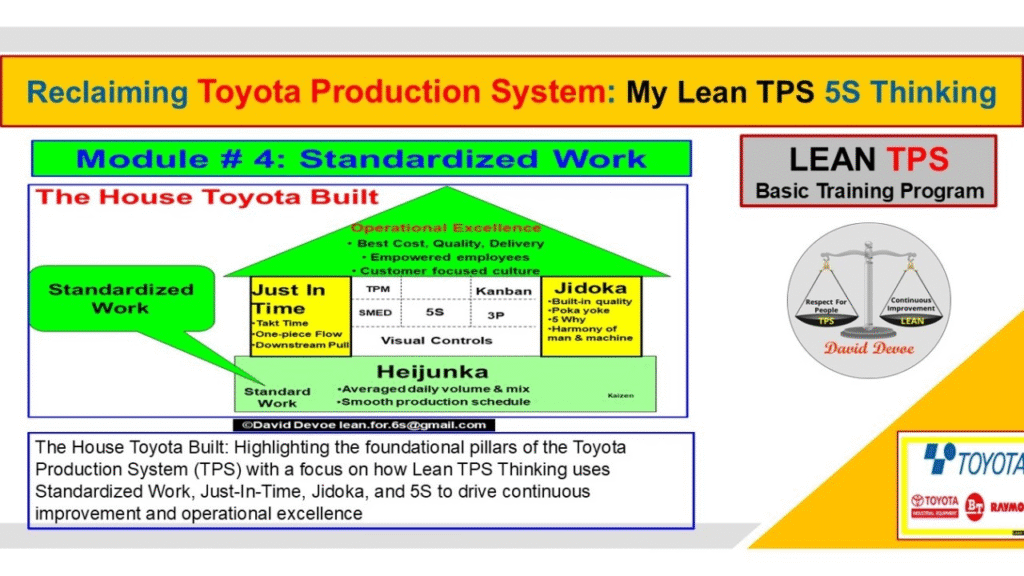

Introduction to Lean TPS and Standardized Work

With over 25 years in operations management, I’ve found that true operational excellence begins with Lean TPS principles, and Standardized Work is essential to this approach. For any organization striving for a sustainable culture of continuous improvement, Standardized Work provides the structure to ensure consistency, quality, and efficiency across all processes.

Standardized Work is more than a process; it’s a guiding philosophy aligned with Lean TPS principles to drive lasting excellence. Within Lean TPS, it sets the base for Kaizen by creating a stable foundation that supports every improvement initiative.

TPS Basic Training — The Standardized Work Chart and Combination Table

In my Lean TPS Basic Training Program, we emphasize two crucial visual tools in TPS: the Standardized Work Chart (SWC) and the Standardized Work Combination Table (SWCT).

Standardized Work Chart (SWC): Captures operator movements, walk times, and material placement, showing inefficiencies and areas for improvement related to value-added tasks.

Standardized Work Combination Table (SWCT): Breaks down time spent on different activities:

Value-Added Activities (directly contributing to product creation)

Non-Value-Added Activities (necessary but non-value-adding steps)

Walk Time, Machine Time, and Wait Time (revealing inefficiencies and improvement opportunities)

These tools allow us to measure performance against Takt Time, creating a structured path for continuous improvement and a baseline for Kaizen activities.

Core Elements of Standardized Work in Lean TPS

Standardized Work relies on three key elements that uphold Lean TPS principles:

Takt Time: The rate at which products must be produced to meet customer demand.

Standardized Work Sequence: Precise steps that operators follow to ensure consistency.

Standard Work-In-Process: Minimum materials required to keep workflows smooth and uninterrupted.

Documenting these elements establishes a baseline that’s continuously refined through Kaizen, ensuring every improvement becomes the new standard.

The Power of Continuous Improvement in Lean TPS

TPS integrates several principles to drive continuous improvement:

Jidoka: Automation with a human touch that stops production when issues arise, addressing quality at the source.

Just-In-Time (JIT): Producing only what is needed to align production with demand and minimize waste.

Heijunka: Leveling production to manage fluctuations and avoid overburdening resources.

Together, Standardized Work and 5S Thinking create a disciplined, organized workplace that fosters a culture of continuous improvement and operational excellence.

The Lean TPS 9-Step Method for Standardizing Work

Standardizing work is essential in Lean TPS for driving quality, efficiency, and consistency.

The Lean TPS 9-Step Method provides a structured approach:

Define the sequence of activities.

Capture standard time, safety, and quality elements.

Calculate the Takt Time.

Allocate cycle time for each task.

Develop a Standard Work Element Sheet (SWES).

Train employees on the standardized process.

Conduct Genchi Genbutsu (“Go and See”) audits.

Address issues quickly and visually.

Revise work standards through Yokoten (sharing best practices).

This method ensures that Standardized Work remains adaptable, evolving to meet organizational needs while reinforcing a culture of Kaizen.

Combining Kaizen and Standardized Work

The SWC and SWCT are indispensable for Kaizen Events and Lean TPS Jishuken (self-directed improvement projects).

By visually representing inefficiencies, these tools enable teams to identify and target specific areas for improvement. Together, they support Lean TPS’s mission to foster a workplace grounded in respect, efficiency, and continuous improvement.

Explore More: Access the White Paper on Lean TPS

To dive deeper into these foundational principles and see how they can apply to your organization, read my white paper:

“Lean TPS: Reclaiming Toyota Production System Principles.”

This comprehensive guide covers Lean TPS 5S Thinking, the Lean TPS 5P Model, and authentic TPS practices that drive sustainable change and operational excellence.

Embrace Continuous Improvement with Lean TPS

If your organization is ready to begin its Lean Journey, implementing Standardized Work is key to achieving long-term success.

My Lean TPS Basic Training Program equips teams with the knowledge and tools to integrate Lean TPS principles into daily operations, creating a culture of respect, discipline, and efficiency.