When Mr. Sadao “Sam” Nomura visited our facilities, he made one thing clear. Quality could never be managed as a department. It had to be designed into every activity of the Toyota Production System. At Toyota, quality was not inspection. It was leadership discipline.

Mr. Nomura taught that defects could not hide in computers or be left for end-of-line correction. They had to be seen, written, and solved in real time. He expected control boards to move from daily to hourly checks. Leaders were to stand at the Gemba, confirm conditions with their own eyes, and take immediate action. He called this Genchi Genbutsu applied to quality.

He was precise about flow. Rework was never to be mixed with normal production. Hospital areas were to be separate and controlled, because once defects entered the main line, flow collapsed. Supplier issues were treated with the same urgency. The worst thirty suppliers were ranked, visited, and coached directly. His target was not fewer defects. It was zero.

Nomura connected quality directly to Standardized Work and Heijunka. Without stability and level loading, he said, problems could not appear in time to be solved. Standardized Work was not paperwork but the method to balance Just in Time and Jidoka. It was how Toyota sustained rhythm without fear.

His most powerful lesson was that quality improvement was not about tools or systems. It was about leadership accountability. Every problem had an owner. Every countermeasure had a time limit. Immediate, one-day, one-week, or one-month response. Anything slower was failure.

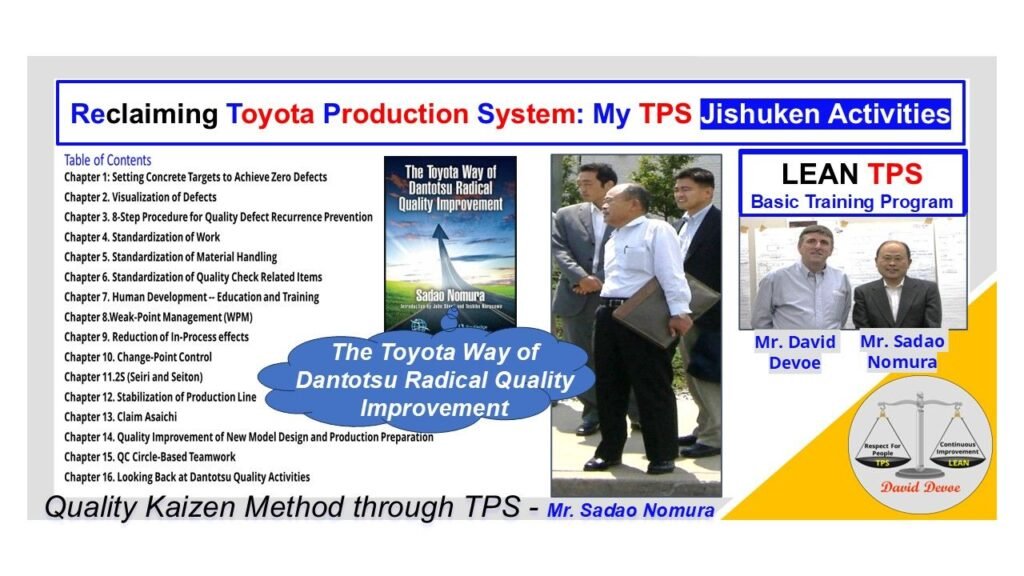

Years later, when Mr. Nomura published The Toyota Way of Dantotsu Radical Quality Improvement, it confirmed everything he had already taught. The same structure, the same rhythm, and the same expectation of zero defects. Dantotsu was not a slogan. It meant radical quality improvement lived through daily discipline.

He showed that Dantotsu Quality is not separate from TPS. It is TPS applied with complete respect for people. It is the courage to confront every defect, the structure to prevent recurrence, and the humility to learn from each problem.

That is what I learned from Mr. Nomura, and it remains the standard I carry forward in my Lean TPS work today.