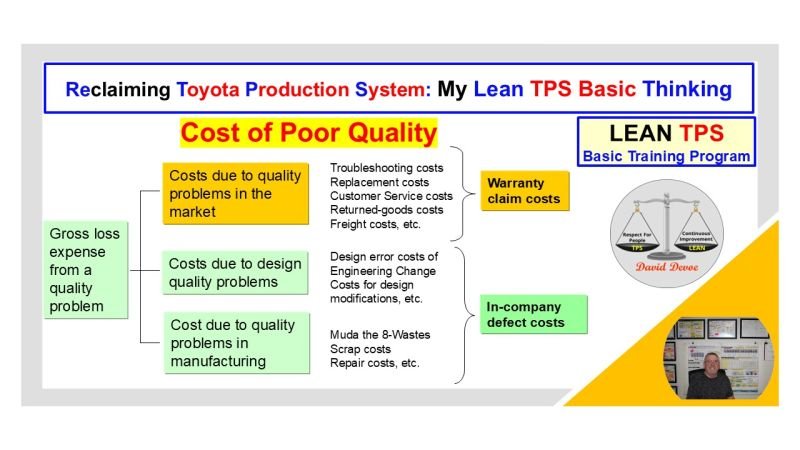

The Cost of Poor Quality (COPQ) represents the hidden losses that occur when processes fail to produce right the first time. It measures the total cost associated with defects, inefficiencies, and waste across the entire product or service lifecycle.

These losses are often underestimated because they are distributed across multiple departments design, production, logistics, and customer service. However, when quantified, COPQ reveals the true cost of instability, waste, and poor process control.

Understanding the Cost Categories

Lean TPS divides COPQ into three primary categories. Each reflects how variation and waste affect overall performance.

1. Quality Problems in the Market (External Failure Costs)

When customers experience defects, the cost extends beyond immediate repairs. External failure costs damage both profitability and reputation.

Examples include:

- Warranty Claims: Costs for repairs, replacements, and service under warranty.

- Returned Goods: Freight, logistics, and administrative expenses tied to returns.

- Customer Service Costs: Troubleshooting, complaint handling, and field support.

- Brand and Trust Loss: Reduced customer loyalty and long-term revenue impact.

Every external failure represents a missed opportunity for prevention. In Toyota’s system, customer complaints are not treated as service issues but as valuable data for process improvement.

2. Design Quality Problems (Internal Failure Costs)

Design-related errors create waste before products reach production. They result from unclear specifications, lack of cross-functional collaboration, or weak verification processes.

Examples include:

- Engineering Change Orders: Cost of redesigning components or correcting errors.

- Design Mistakes: Incomplete or inaccurate drawings that require rework.

- Testing and Validation Costs: Repeated verification cycles due to instability.

- Wasted Resources: Lost time and materials during design correction.

In Lean TPS, prevention begins with design. Quality must be designed into the product and process, not inspected later.

3. Manufacturing Quality Problems (Internal Failure Costs)

In manufacturing, the cost of defects is magnified by volume. A single unstable process can create hundreds of defective parts before detection.

Common examples include:

- Scrap: Nonconforming parts that cannot be recovered.

- Rework: Additional labor and material to fix defects.

- Line Stoppages: Production downtime caused by abnormalities.

- 8 Wastes: Overproduction, waiting, transportation, excess motion, inventory, overprocessing, defects, and underutilized people.

When Standardized Work and visual control are missing, quality problems spread quickly across operations. Toyota prevents this through immediate detection and response, supported by Jidoka and Andon systems.

Why Reducing COPQ Matters

Reducing COPQ is not simply a financial activity it is a leadership responsibility. Every hidden cost signals a weakness in process control, training, or communication.

Lean TPS uses COPQ to identify where resources are being lost and how processes can be improved. Eliminating these costs strengthens both customer satisfaction and organizational capability.

Key benefits of addressing COPQ:

- Improved product reliability and customer confidence.

- Higher process stability and throughput.

- Reduced rework and scrap costs.

- Greater profitability without price increases.

Prevention Through Lean TPS

Prevention is the most cost-effective form of quality control. Lean TPS achieves prevention by embedding quality into every stage of the process:

- Design Phase: Applying error-proofing (Poka Yoke) and early quality reviews.

- Production Phase: Standardized Work, Jidoka, and visual controls for detection.

- Leadership Phase: Gemba-based learning, structured problem-solving, and accountability for maintaining standards.

When organizations invest in training and standardization, they convert hidden losses into long-term gains. Prevention costs are far lower than the expense of correction or failure.

A System to Build Capability

The Cost of Poor Quality framework within the Lean TPS Basic Training Program helps organizations see beyond symptoms. It builds the understanding needed to identify, measure, and prevent losses before they occur.

By managing COPQ, leaders develop the discipline to view quality not as inspection but as a system for learning and improvement.