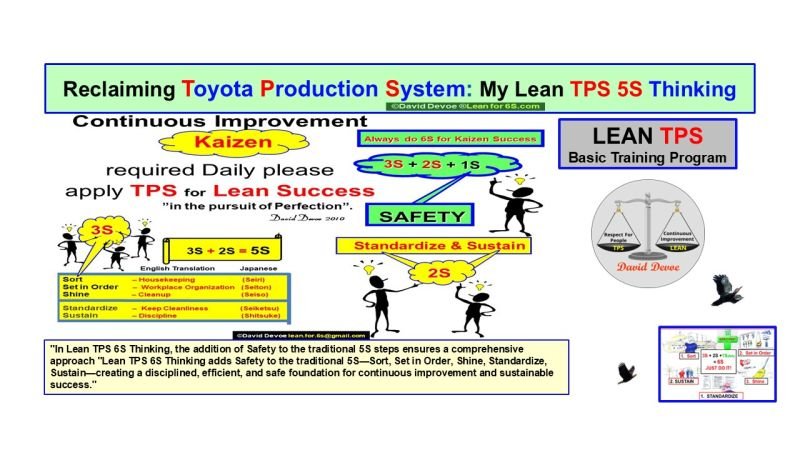

Every Lean TPS transformation begins with structure. The 5S system creates the foundation for organization, efficiency, and flow. However, true stability cannot exist without safety. My Lean TPS 6S Thinking integrates Safety as the sixth pillar, ensuring that every improvement effort begins with a secure environment that supports people, process, and continuous learning.

At Toyota, 5S is never treated as a housekeeping exercise. It is a system of thinking that connects discipline, visual control, and standardization. By adding Safety to the model, 6S Thinking transforms Lean TPS from an efficiency system into a complete human-centered framework for operational excellence.

The Foundation of Lean TPS 6S Thinking

The traditional 5S steps—Sort, Set in Order, Shine, Standardize, and Sustain—create visual order and consistency. Each step builds on the previous one to make work visible, measurable, and repeatable. Lean TPS 6S Thinking strengthens this structure by embedding Safety into every activity.

- Sort: Remove unnecessary items and materials that create hazards or visual confusion.

- Set in Order: Arrange tools, equipment, and materials to minimize motion and ergonomic strain.

- Shine: Use cleaning as inspection. A clean workplace exposes potential safety and quality problems before they escalate.

- Standardize: Create consistent visual standards that define safe work conditions and prevent variation.

- Sustain: Reinforce daily discipline through leader engagement, training, and visual accountability.

- Safety: Ensure that every process, tool, and condition protects people and enables improvement to occur safely.

Safety is not an add-on. It is a mindset that defines how standards are designed, implemented, and improved. When safety is integrated into each 5S element, the result is a workplace where quality, efficiency, and morale improve simultaneously.

Why Safety Must Lead Improvement

Organizations that treat safety as a separate initiative often struggle to sustain improvement. When accidents, near misses, or unsafe conditions occur, productivity and trust decline. Lean TPS 6S Thinking prevents these setbacks by embedding safety into daily work practices.

At Toyota BT Raymond, the implementation of Lean TPS 6S Thinking created a visible and measurable change in shopfloor behavior. Visual cues, defined walkways, and ergonomic layouts reduced motion waste while improving safety performance. Standardized inspection routines ensured that unsafe conditions were corrected immediately rather than after incidents occurred.

By starting every Kaizen with safety in mind, improvement activities became more focused, stable, and sustainable. The result was not only fewer risks but also stronger teamwork, clearer communication, and faster problem-solving.

A Complete System for Sustainable Success

Lean TPS 6S Thinking connects people, process, and environment in a way that ensures improvement does not compromise safety or quality. It represents the maturity of Lean TPS practice—where technical improvement and human development advance together.

Leaders who practice 6S Thinking reinforce Toyota’s principle of Respect for People. They demonstrate that safety and efficiency are not competing priorities but interdependent requirements for excellence.

A true Lean TPS workplace is built on structure, discipline, and care for those who perform the work. By integrating Safety into 5S, organizations create the foundation for sustainable improvement and prepare for the next level of Kaizen maturity.