Quality as a Governed System, Not a Cultural Value

Respect for People is often described as a value or cultural principle. In many organizations, it is treated as a belief to be promoted, reinforced, or modeled through behavior.

In practice, Respect for People is a system outcome created by Quality-first design and enforced standardization. Where systems are well designed, people are not required to compensate for ambiguity, instability, or weak decision structures. Where systems are weak, Respect for People is reduced to intention rather than reality.

At Toyota, Quality-first thinking was never dependent on identical work sequencing. Work varied from cycle to cycle, yet a common Quality structure remained intact. That structure determined whether people produced value or were forced to compensate for weak systems. Quality was governed through structure, standardization, and daily confirmation rather than motivation or slogans.

This distinction matters. When Quality is governed by system design, people are protected from the need to guess, improvise, or absorb defects. When Quality is left to interpretation, people carry the burden through overwork, rework, and constant adjustment.

Quality as a Single System

Quality at Toyota is not treated as a set of independent stages or departmental responsibilities. It operates as a single, integrated system. Weakness in one area does not remain isolated. It forces compensation elsewhere, often far from the original decision point.

Four interrelated forms of Quality support this structure.

1. Planning Quality

Planning Quality establishes clarity before work begins. Product concepts are defined to satisfy customer needs at the outset, before downstream commitments are made. This stage determines whether later work will be executed with confidence or correction. Clear intent at the planning stage prevents downstream guessing and late-stage trade-offs that people are otherwise required to absorb. When planning is weak, ambiguity migrates downstream and becomes human effort.

2. Design Quality

Design Quality translates intent into explicit requirements. Reliability is built into the product and process through deliberate design decisions rather than inspection or adjustment after the fact.

Design intent must be concrete and testable. Engineers and operators should not be required to interpret what “good” looks like. When design intent is unclear, people compensate by making judgment calls that should have been resolved upstream.

3. Manufacturing Quality

Manufacturing Quality protects execution. Products and processes are built as designed, and deviations surface immediately instead of being absorbed by people.

Standardized methods play a critical role at this stage. They prevent Quality from depending on memory, individual effort, or heroics. When deviation is hidden or tolerated, people absorb instability through extra work, workarounds, and informal fixes.

4. Sales and Service Quality

Sales and Service Quality extends responsibility across the full product life cycle. Customers can withdraw maximum performance from the product because upstream decisions were made correctly and verified early.

Service issues often reveal weaknesses in planning, design, or manufacturing that were never fully closed. Treating service as part of the Quality system prevents those weaknesses from being normalized.

The Human Cost of Weak Quality Systems

These four elements operate as a single Quality system. Weakness in any one area forces compensation elsewhere, and that compensation consistently appears in human terms. Frustration increases as people deal with recurring problems. Overburden becomes normal as effort shifts from value creation to recovery. Learning time disappears as work becomes reactive.

Respect for People is not lost through intent. It is lost through system design.

Standardization as Governance

Standardization enables this system to function by defining a method that can be followed, verified, and improved where the work is performed, rather than serving as documentation for compliance.

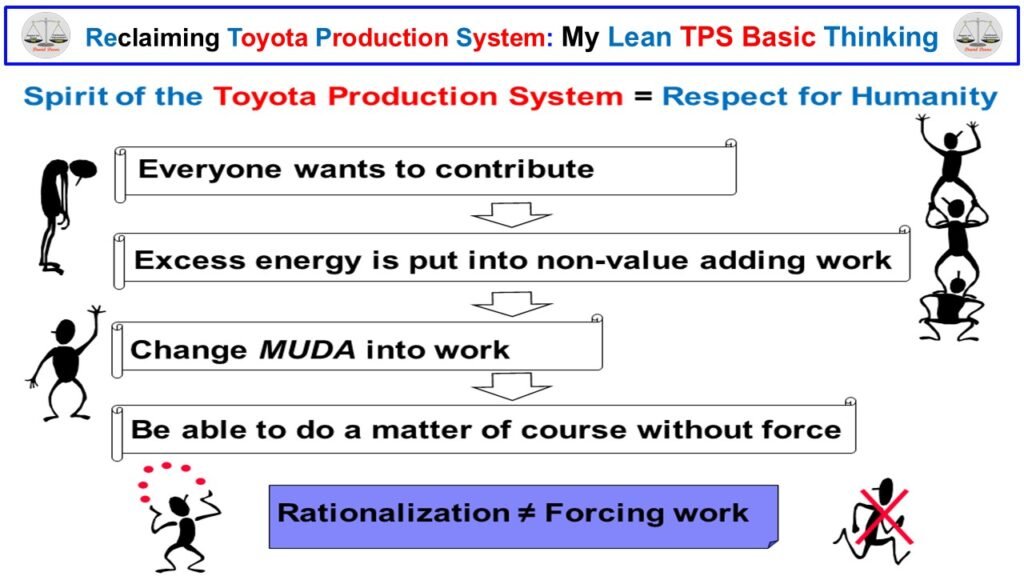

Standardization in Lean TPS is not about prescribing identical motion. It establishes a stable method that makes abnormalities visible and learning possible. Without standardization, problems remain ambiguous and responsibility becomes negotiable.

Effective standards must work in real conditions. Methods must be followed as written. Improvements must replace the existing method rather than becoming exceptions. Daily use matters more than periodic review.

When standards are used daily, energy stops flowing into compensation work. Effort shifts from recovery to improvement. Quality becomes predictable rather than heroic.

Respect for People as an Outcome

Respect for People does not come from motivation or messaging. It emerges when systems are designed so people are not required to compensate for structural weakness.

When Quality is planned, designed, built, and sustained through governed systems, people are allowed to focus on meaningful work. Ambiguity is reduced. Judgment is applied where it adds value, not where it fills gaps.

This is Respect for People in practice.

Lean TPS as Applied Work

Lean TPS represents my applied work documenting and operating these principles beyond Toyota. The focus is not interpretation or adoption, but system operation. Quality, standardization, and governance are treated as inseparable.

This work, including ongoing writing on Mixed-Model Human–Humanoid environments, is published at LeanTPS.ca. The same system logic applies as execution environments evolve. Human capability must be protected through design, not expectation.

For continued examination of system design, Quality, and leadership accountability, follow the newsletter Lean TPS: The Thinking People.