Lean TPS 5S Thinking for Mixed-Model Human–Humanoid Production

A Quality System for Safe, Predictable, and Collaborative Human–Robot Work

5S Thinking creates stable, visible workplace conditions that protect Quality and support reliable human–humanoid work.

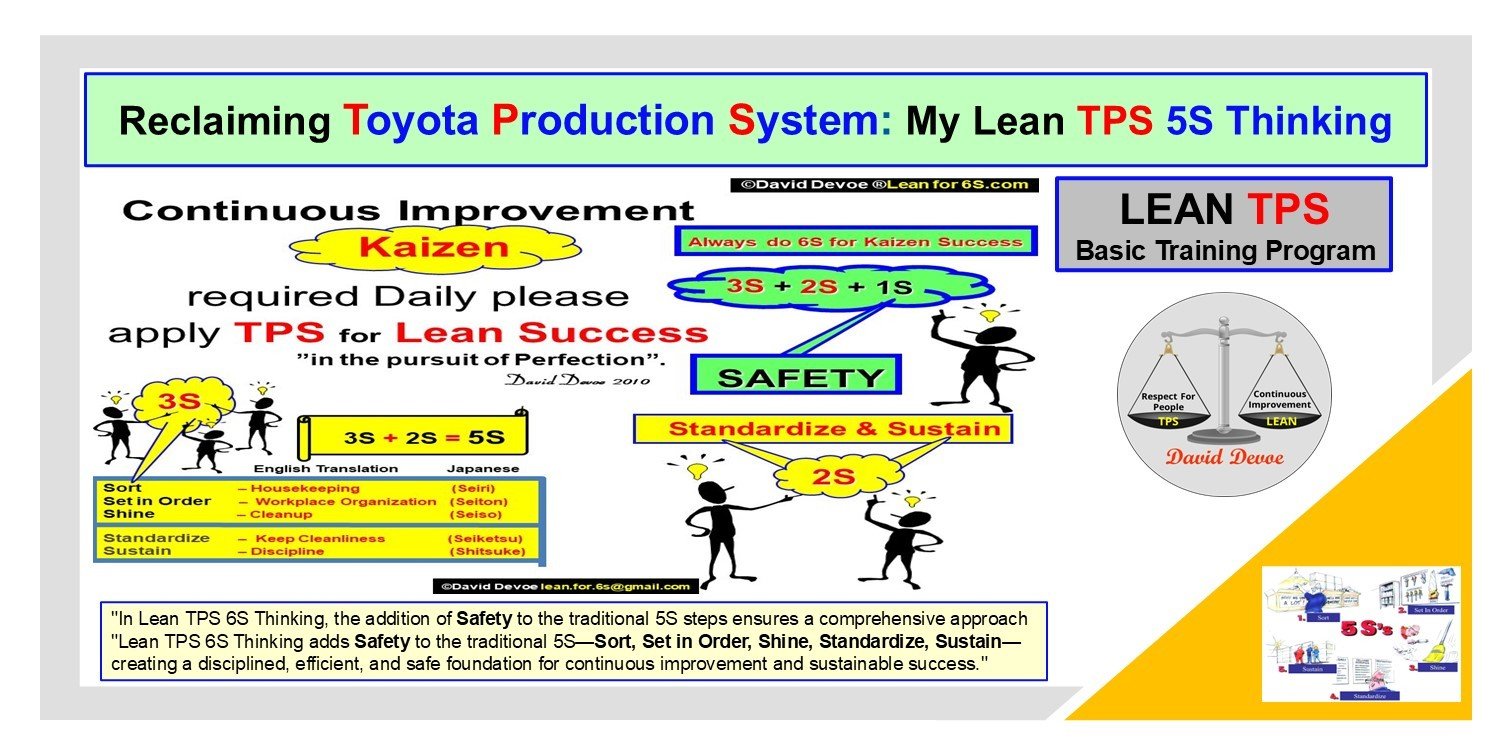

Lean TPS 5S Thinking establishes the workplace conditions required for consistent Quality, stable flow, and safe collaboration between humans and humanoid robots. In mixed-model environments, the workplace is a shared system. Humans and humanoid robots depend on the same physical layout, the same material presentation, the same surface conditions, and the same visual signals to perform work correctly. When these conditions are unstable, variation enters the process before work begins. When these conditions are controlled, Quality is built into the environment and protected every cycle. 5S Thinking is therefore not an improvement activity or a housekeeping practice. It is the structural discipline that makes reliable work possible.

At Toyota, 5S has always been treated as a Quality system. Its purpose is to ensure the workplace is ready for work at the start of every shift and remains ready throughout the day. Readiness means tools are in defined locations, materials are presented correctly, paths are clear, surfaces are clean, and abnormalities are visible the moment they appear. These conditions allow people to perform work consistently and allow machines and humanoid robots to operate within known, predictable boundaries. Without this stability, Standardized Work cannot be executed as designed, flow cannot be maintained, and Jidoka cannot function at the source.

Mixed-model human–humanoid production makes this requirement explicit. Humans can adapt to clutter, missing items, poor lighting, or shifting layouts. Humanoid robots cannot. Embodied intelligence relies on stable geometry, clear visual references, clean surfaces, and consistent spatial relationships to perceive the environment accurately and execute motion safely. Any deviation in these conditions increases the risk of misrecognition, incorrect movement, or unsafe interaction. 5S Thinking creates the baseline that prevents these risks by defining and maintaining the physical and visual order of the workplace.

This whitepaper positions 5S Thinking as the foundation of Lean TPS because it creates the conditions that protect Quality before work begins. It explains how workplace stability enables predictable human performance, reliable humanoid operation, and immediate detection of abnormality. 5S Thinking converts the environment itself into a control mechanism. Quality is not inspected after the fact. It is embedded in the way the workplace is designed, organized, and restored every day.

2. Why 5S Thinking Must Come First in Lean TPS

Workplace Stability as the Non-Negotiable Precondition for Quality

Lean TPS 5S Thinking must come first because no Toyota Production System method can function without a stable workplace. Before Standardized Work can be written correctly, before flow can be established, and before Jidoka can detect abnormality at the source, the physical environment must be controlled. An unstable workplace introduces variation before work begins. Tools move, materials accumulate, locations drift, and surfaces deteriorate. This instability prevents leaders from seeing the real condition of work, forces people to compensate through improvisation, and creates environments where Quality depends on individual effort instead of system design.

In Lean TPS, the workplace is treated as part of the production system, not as background. Uncontrolled processes create hidden waste in the form of excess motion, delays, errors, and breakdowns. They also hide problems. When items do not have defined locations, when inventory levels are unclear, and when work areas change unpredictably, abnormal conditions blend into daily work and go unnoticed. This prevents accurate observation, delays problem detection, and undermines the ability to maintain consistent performance. In mixed-model human–humanoid production, these conditions are unacceptable. Humanoid robots require predictable geometry, clear paths, stable material presentation, and consistent visual references. When the environment changes without control, robots cannot navigate reliably, interpret the workspace accurately, or execute tasks safely.

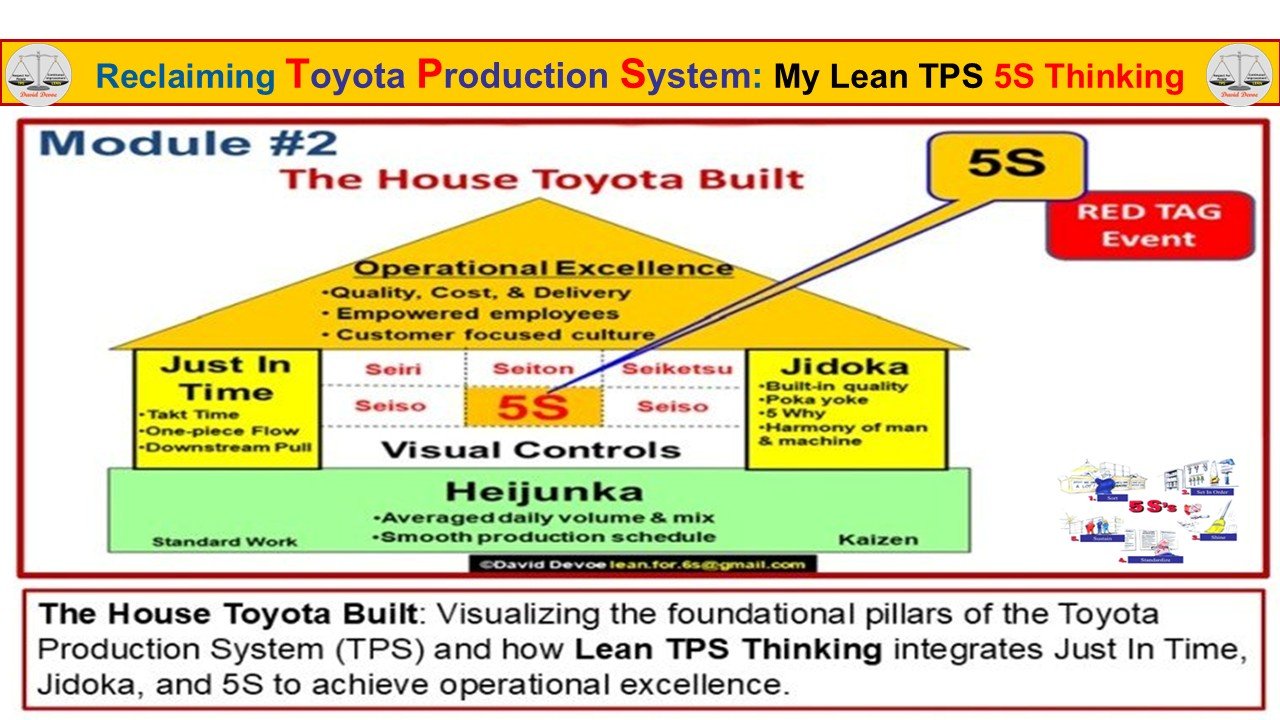

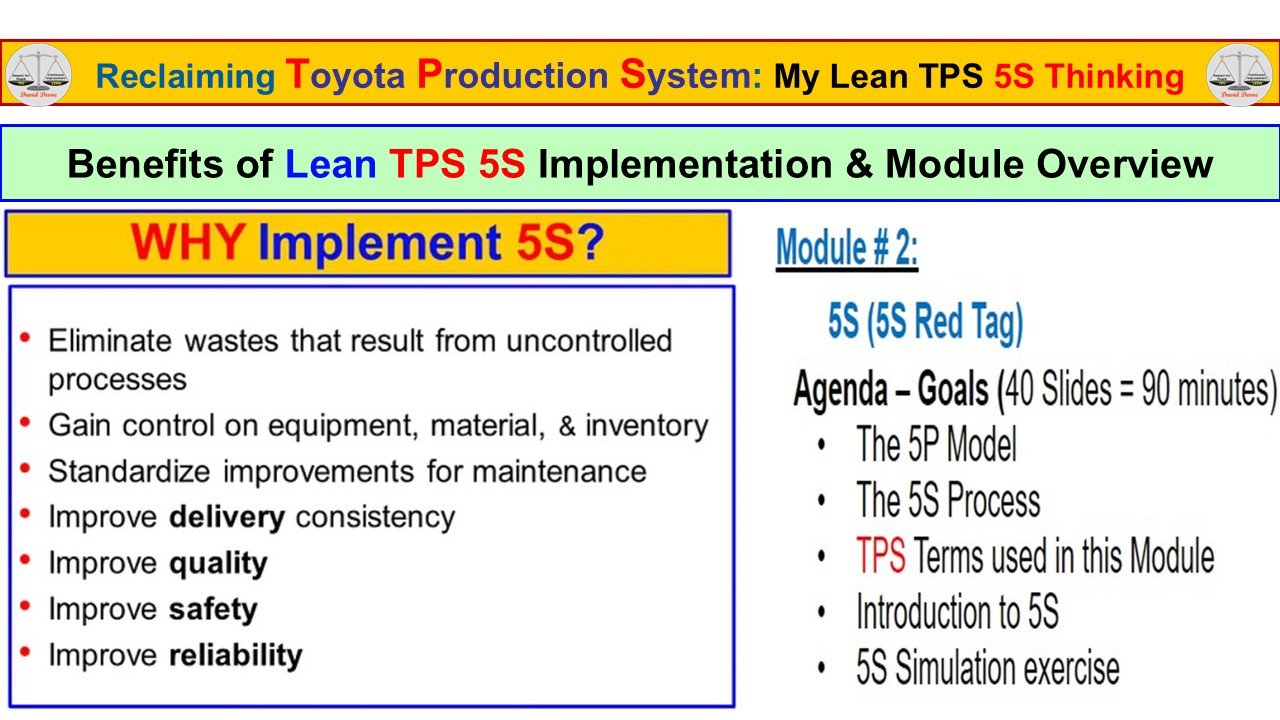

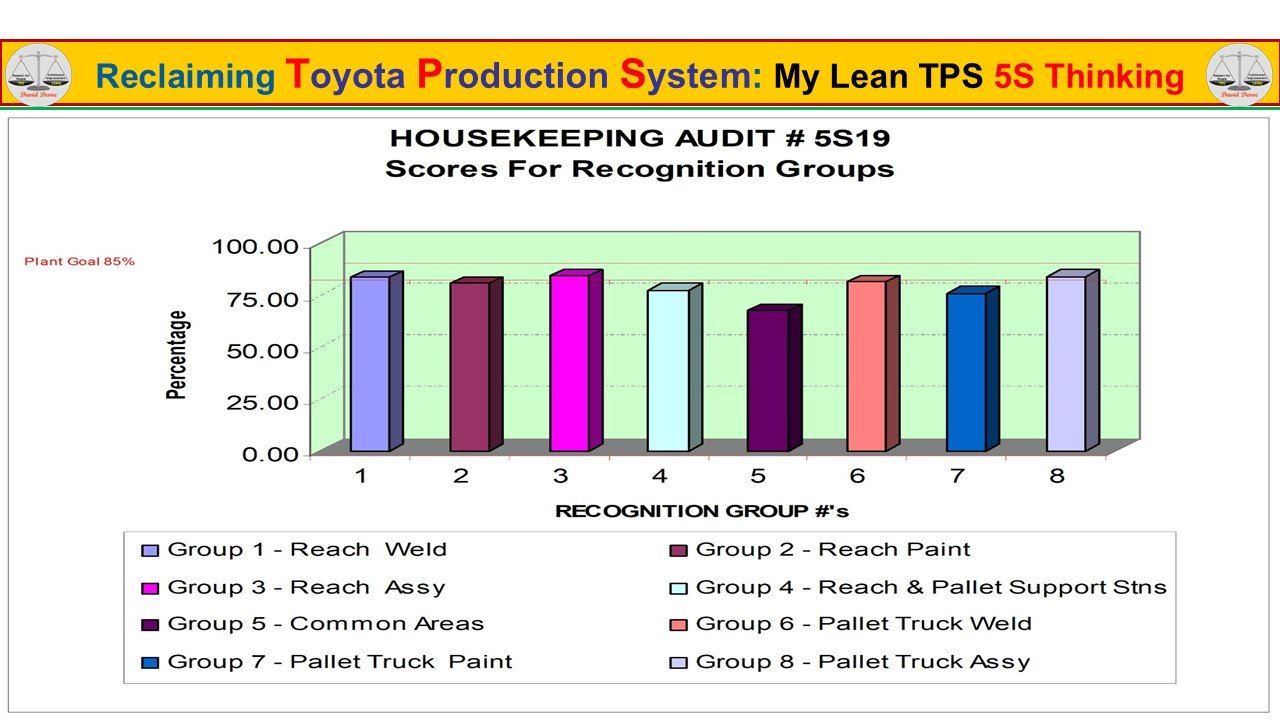

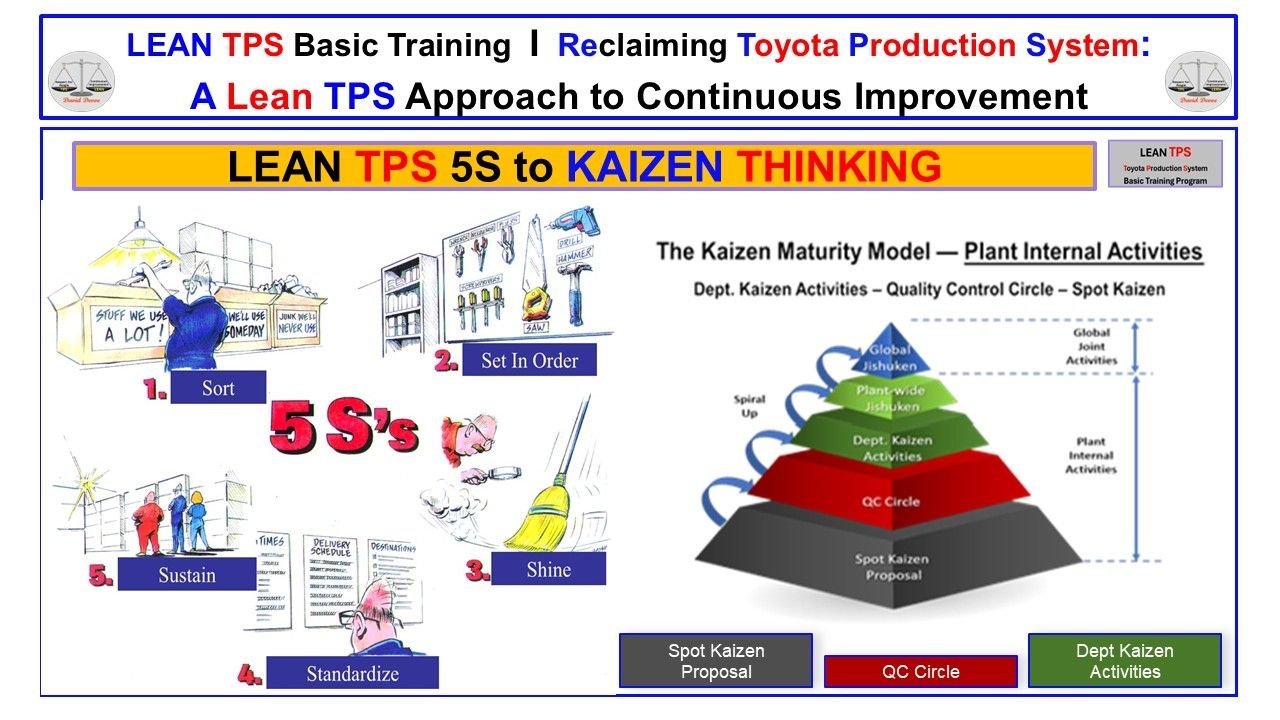

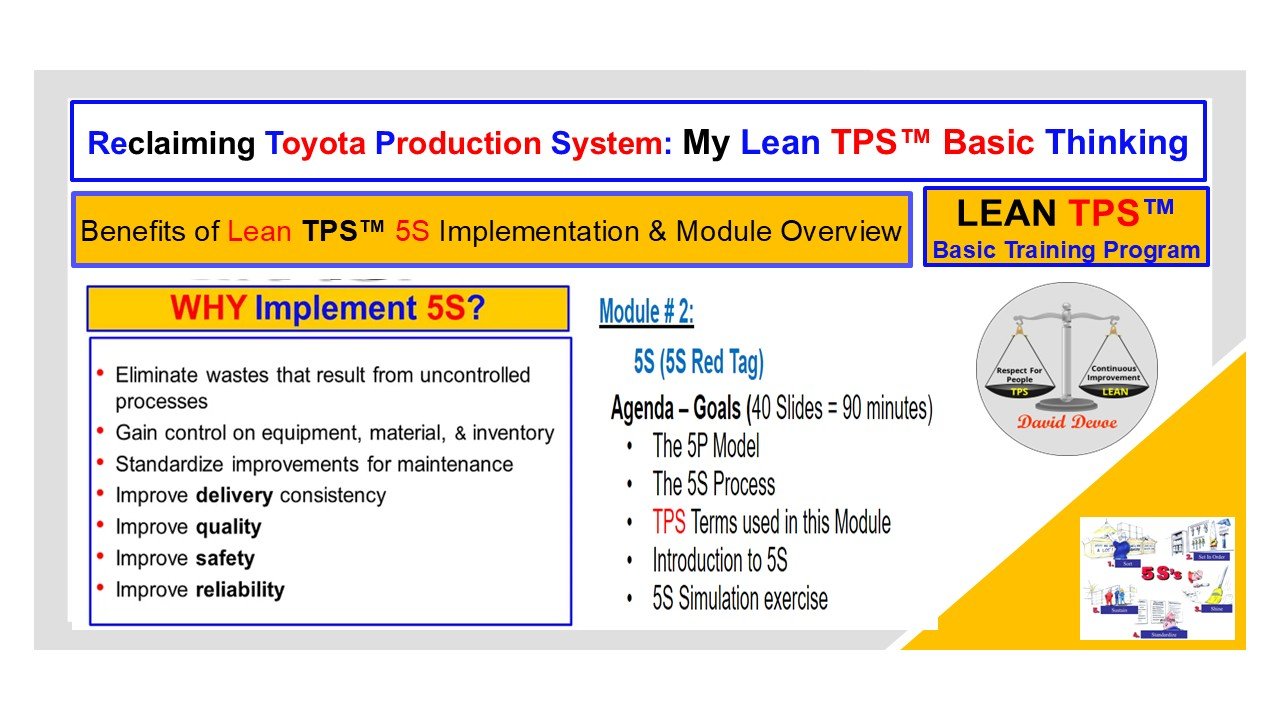

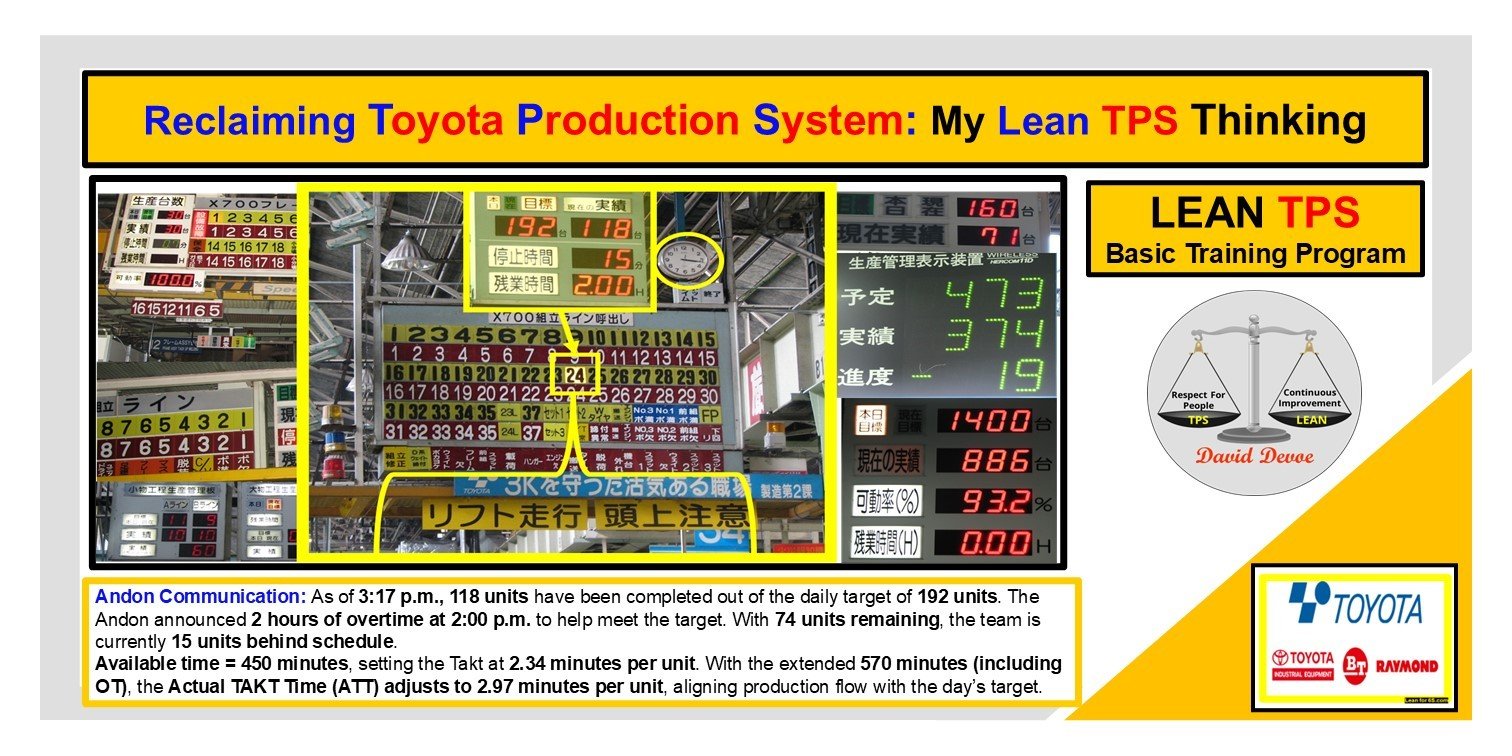

Figure 2. Why Implement 5S Thinking

5S Thinking creates stable work, clear visibility, and controlled materials so humans and humanoid robots can perform safely and consistently.

5S Thinking removes this instability by establishing control over the physical and visual environment. It creates the baseline conditions where work can be performed as designed and deviations become immediately visible. This is why 5S is not positioned as an improvement tool within Lean TPS. It is the prerequisite that allows all other methods to operate as intended. When workplace stability exists, Quality can be built into the process, flow can be sustained, and abnormality can be detected at the moment it occurs. Without this foundation, Lean TPS cannot function as a system.

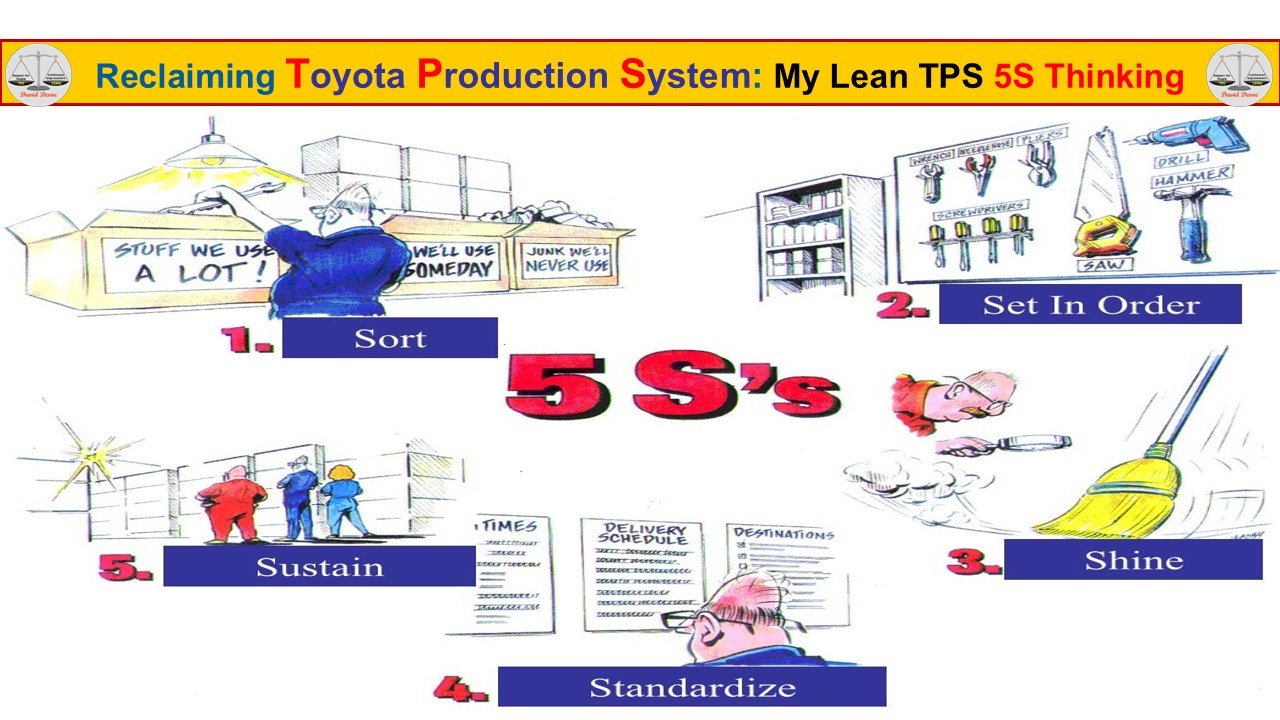

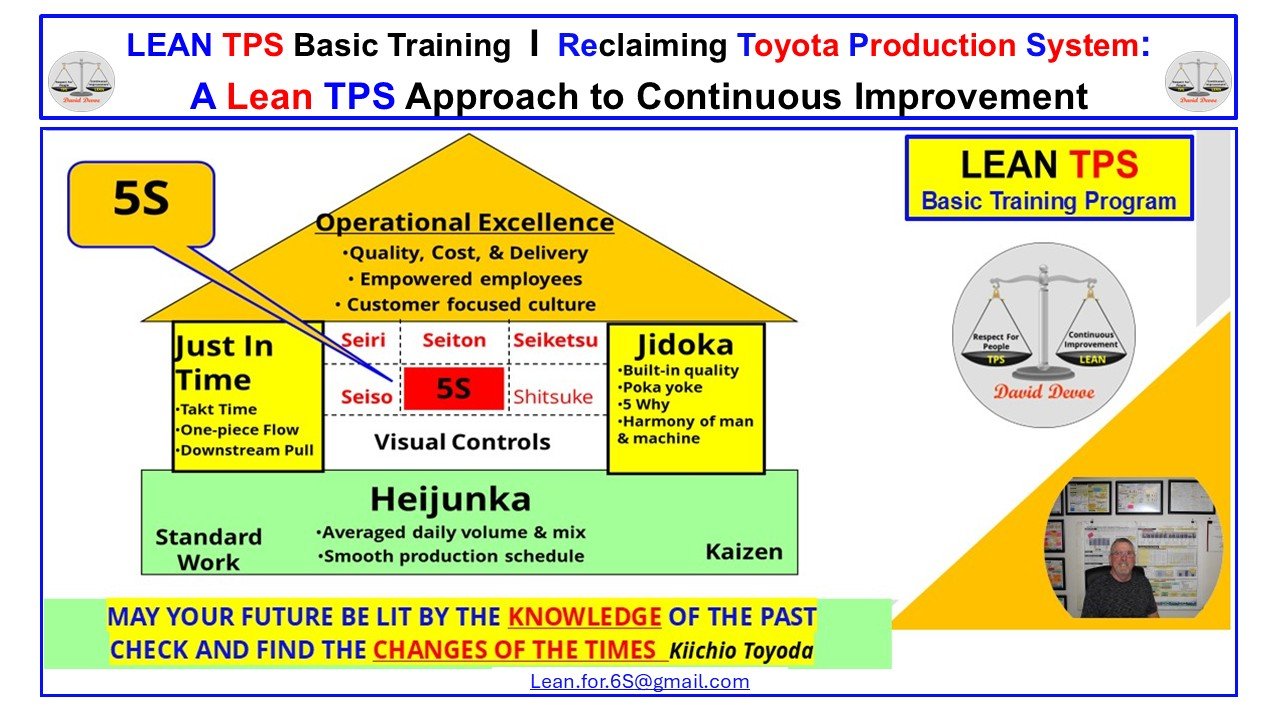

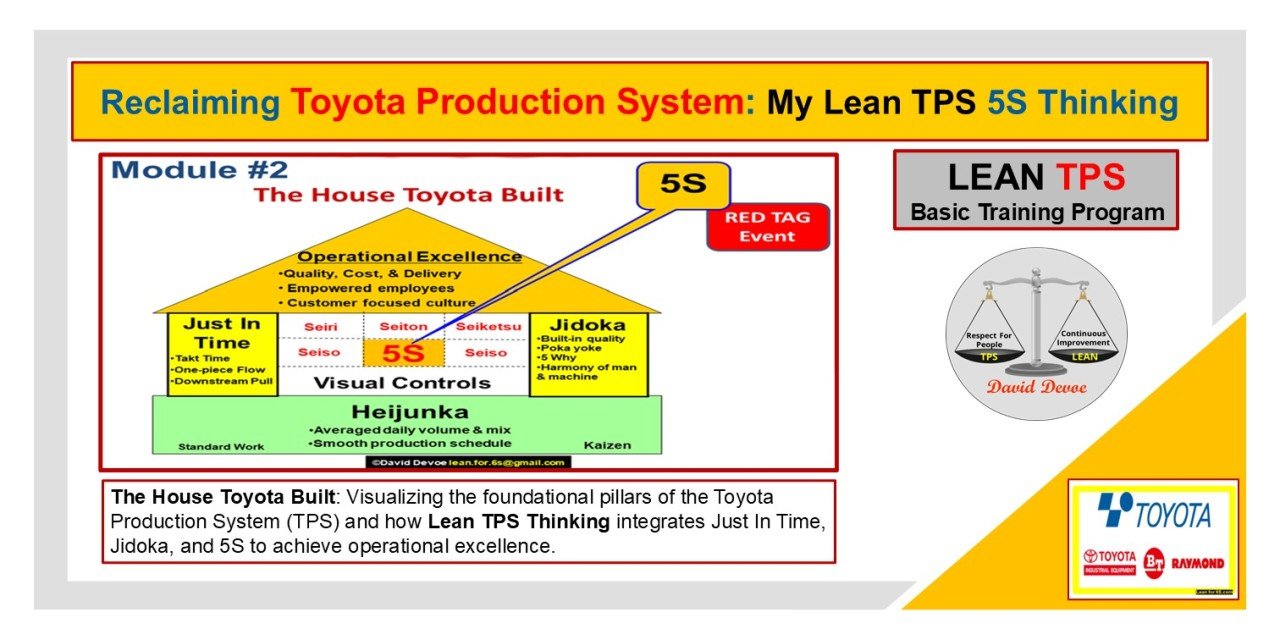

3. Understanding the Five Steps of 5S Thinking

How the Five Steps Create the Workplace Stability Required for Quality

The Five Steps of 5S Thinking define the structural sequence Toyota uses to create and maintain workplace stability. They are not independent activities and they are not interchangeable. Each step removes a specific form of instability that degrades Quality, hides abnormality, and disrupts flow. When performed in sequence, the five steps convert an uncontrolled workplace into a predictable environment where work can be performed consistently by people and supported reliably by systems and machines. When performed out of sequence or partially, instability remains embedded in the environment and problems continue to surface downstream.

In Lean TPS, the purpose of the Five Steps is not visual appeal. The purpose is reliability. A workplace that appears clean but does not support fast detection of abnormality, consistent material presentation, or stable motion paths is not a 5S workplace. The five steps exist to remove variation from the environment before it reaches the work. This is especially critical in mixed-model human–humanoid production, where environmental variation directly affects perception accuracy, motion planning, and safe interaction. Humans may compensate for instability. Humanoid robots cannot. The Five Steps create the minimum conditions required for both to perform work with predictable Quality.

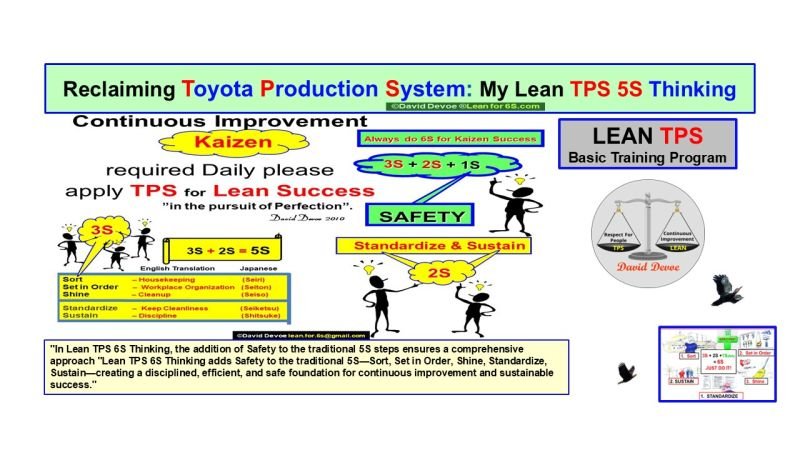

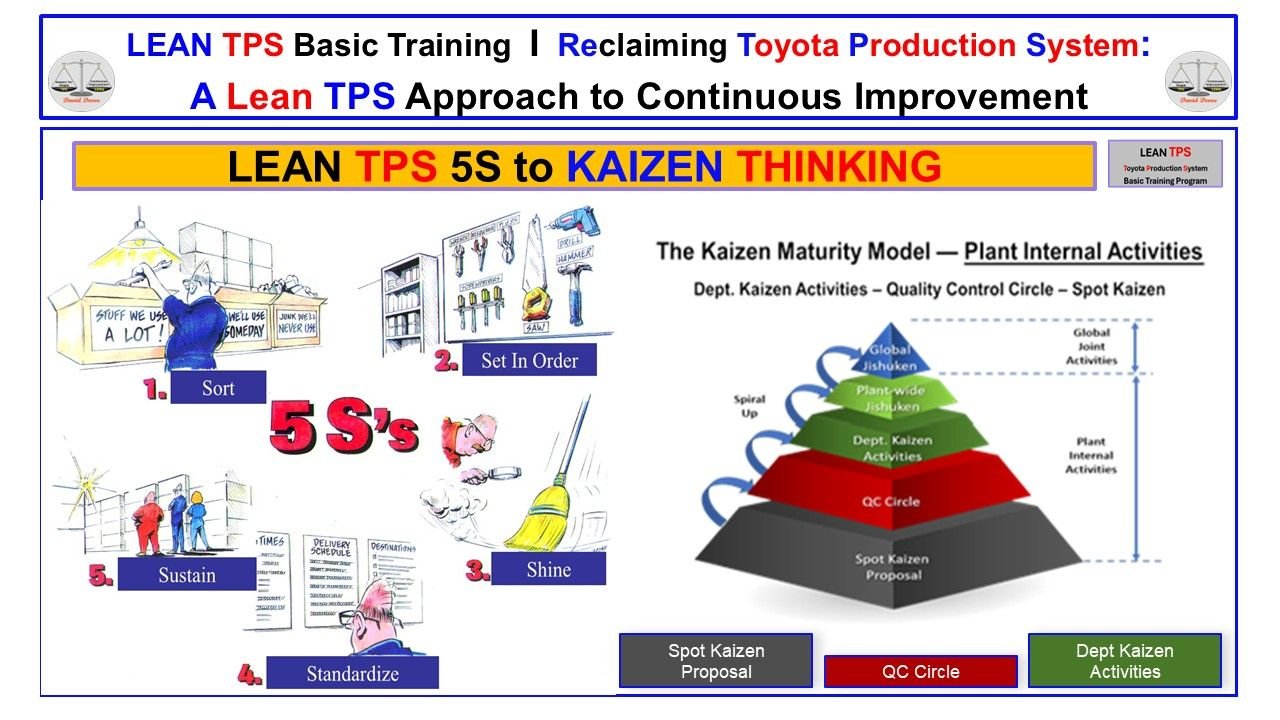

Figure 3: The Five Steps of 5S Thinking

The five steps create the organized, stable workplace needed for visual clarity and reliable mixed-model human–humanoid work.

The Five-Step Sequence as a Stability System

Sort removes what does not support current work. It limits the environment to only what is required, reducing visual noise, physical obstruction, and unnecessary decision making. This immediately exposes hidden problems and restores space needed for safe movement and clear observation. Without Sort, excess items absorb variation and mask abnormalities that should be addressed directly.

Set in Order defines the exact location, orientation, and quantity for every remaining item. It establishes a fixed relationship between people, tools, materials, and equipment. This removes searching, reduces motion, and ensures that every task begins from the same physical starting point. For humanoid robots, Set in Order is essential because even small shifts in location or orientation can cause recognition errors or unsafe motion.

Shine restores the physical condition of the workplace so abnormalities become visible. Cleaning is performed as inspection. Surfaces, tools, and equipment are returned to a known condition so leaks, wear, looseness, and contamination stand out immediately. Shine protects Quality by exposing deterioration early and by maintaining the environmental conditions required for accurate sensing and stable movement.

Standardize locks the first three steps into repeatable routines. It defines who does what, how often, and how correct conditions are verified. Without Standardize, improvements collapse under daily pressure and variation re-enters the system. Standardize ensures that stability is not dependent on individual effort but is maintained through defined expectations and confirmation.

Sustain ensures the discipline required to maintain stability over time. It is a leadership responsibility supported by observation, coaching, and accountability. Sustain prevents drift back into disorder and ensures that the workplace remains aligned with its designed condition. In human–humanoid environments, Sustain is non-negotiable because small lapses in 5S conditions can quickly create safety risk or operational failure.

Together, the Five Steps function as the first structural discipline of Lean TPS. They create a workplace where abnormalities are visible, flow is predictable, and Quality is protected before work begins. This sequence establishes the controlled environment required for Standardized Work, Jidoka, and continuous improvement to function as an integrated system rather than as isolated practices.

4. Sort as the First Act of Environmental Control

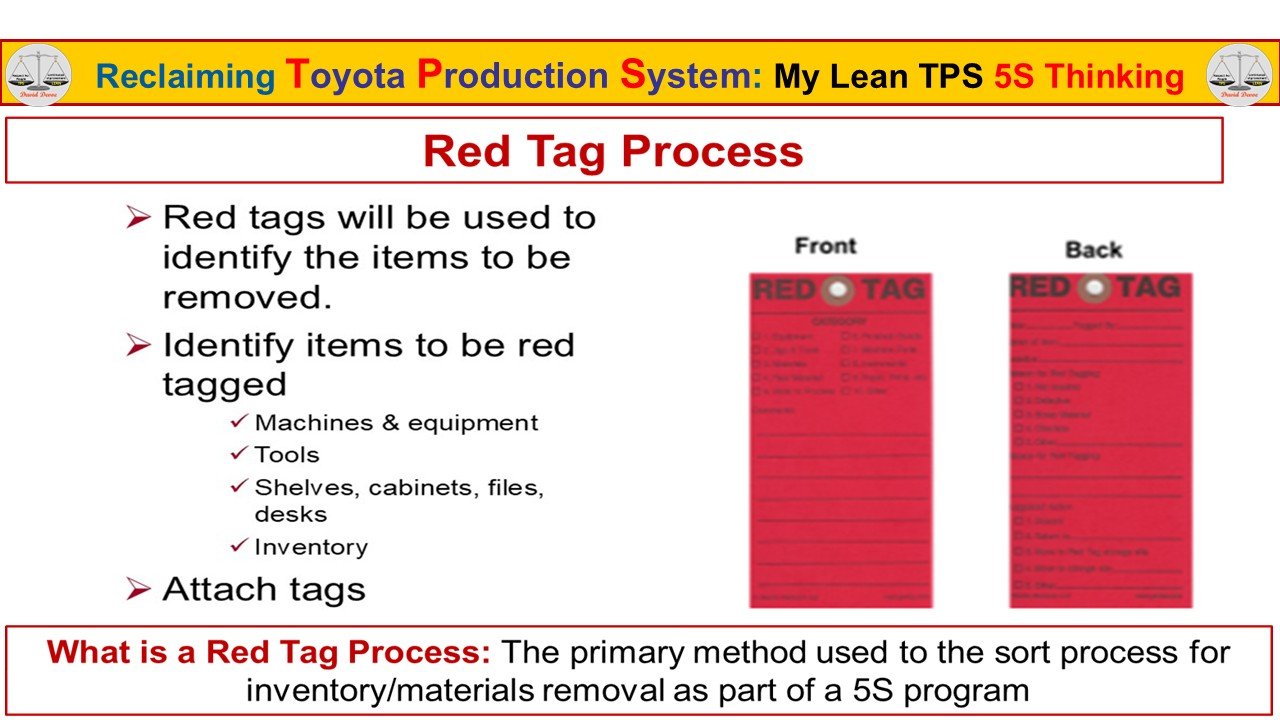

Removing Instability at the Source Through the Red Tag Process

Sort is the first step of 5S Thinking because it directly removes the physical causes of instability from the workplace. Before order, cleanliness, or standardization can be effective, the environment must be reduced to what is truly required to perform the work. Excess items create visual noise, obstruct movement, absorb variation, and hide problems. When unnecessary machines, tools, materials, and inventory remain in the work area, they distort the real condition of the process and force people to work around the environment instead of within a controlled system.

In Lean TPS, Sort is not a subjective cleanup activity. It is a deliberate act of environmental control designed to expose reality. Items that are rarely used, no longer required, duplicated, or incorrectly located introduce uncertainty into daily work. They make it difficult for leaders to see abnormalities, for operators to perform tasks consistently, and for systems to detect deviation. In mixed-model human–humanoid production, this instability is amplified. Humanoid robots depend on uncluttered spaces, defined boundaries, and consistent spatial relationships. Unnecessary items introduce collision risk, interfere with navigation, and degrade perception accuracy.

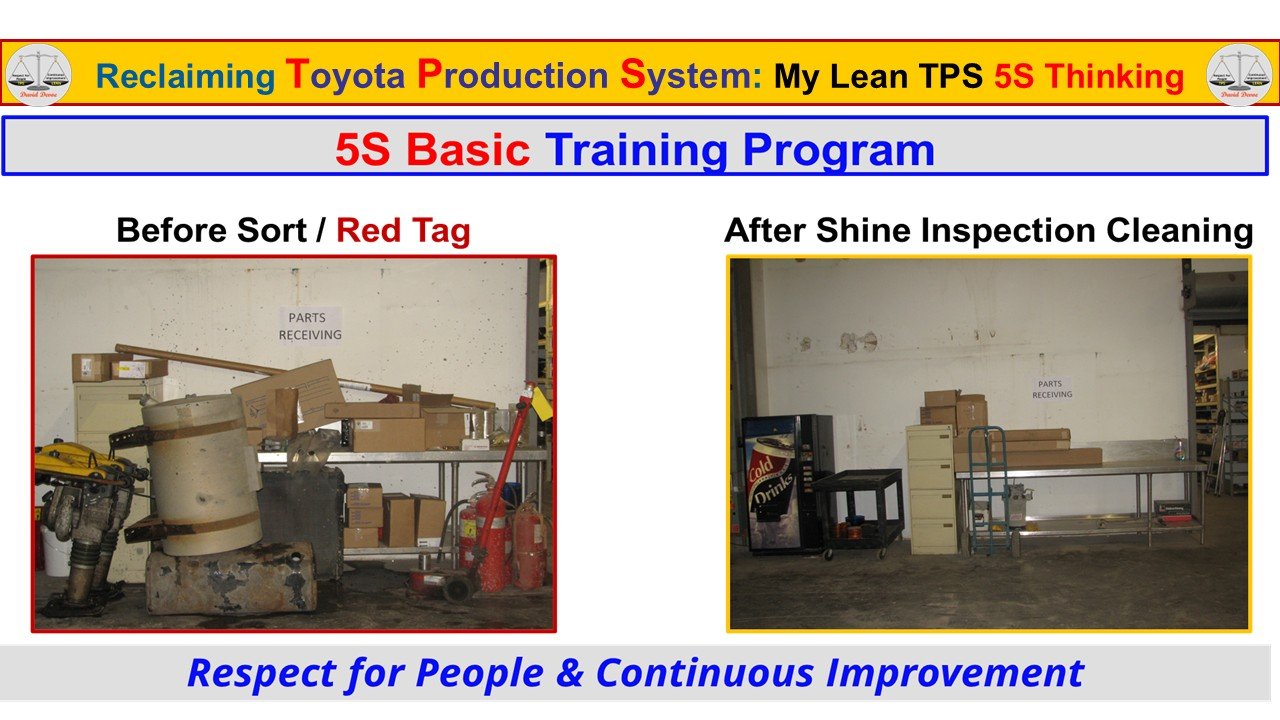

Figure 4: Red Tag Process

The Red Tag Process is the primary method used to identify and remove items that do not support current work, restoring visibility and environmental control.

Using Red Tags to Expose and Remove Hidden Instability

The Red Tag Process provides a structured method for making decisions about what belongs in the workplace. Rather than debating usefulness abstractly, items are physically identified, tagged, and evaluated based on actual need. This shifts discussion from opinion to evidence. Items that do not support current production are removed from the work area and placed in a designated evaluation zone, immediately freeing space and restoring clarity.

Red Tagging exposes sources of waste that are often normalized over time. Excess inventory, obsolete equipment, unused tools, and informal storage locations accumulate gradually and are rarely questioned. By tagging these items, Sort interrupts this drift and forces explicit decisions about retention, relocation, or removal. The result is a workplace that reflects real operational requirements rather than historical accumulation.

From a Quality perspective, Sort eliminates conditions that hide defects and delay detection. With fewer items present, abnormalities stand out quickly. From a safety perspective, removing excess items clears paths of travel and reduces collision risk. For humanoid robots, Sort establishes the clean spatial envelope required for reliable navigation and safe interaction with people.

Sort sets the foundation for all subsequent 5S steps. Without removing what is unnecessary, Set in Order cannot define stable locations, Shine cannot reveal true equipment condition, and Standardize cannot sustain control. The Red Tag Process is therefore the first act of discipline in Lean TPS 5S Thinking. It restores environmental truth and creates the controlled conditions required to protect Quality before work begins.

5. Identifying Uncontrolled Conditions That Require a Red Tag Event

Making Instability Visible Before It Damages Quality

Uncontrolled conditions develop gradually in most workplaces. Excess inventory accumulates, temporary storage becomes permanent, equipment is parked where space is available rather than where it belongs, and work areas absorb clutter as daily pressure increases. Over time, these conditions are normalized. What was once recognized as abnormal becomes accepted as part of daily work. This normalization hides instability, degrades Quality, and prevents leaders from seeing the true condition of the process. In Lean TPS, the Red Tag Event exists to interrupt this drift and reestablish environmental truth.

Uncontrolled conditions are not limited to obvious clutter. They include unclear ownership of space, undefined limits for inventory, equipment stored without purpose, and materials staged without a clear production requirement. These conditions distort flow, increase motion, and introduce safety risk. They also create environments where work cannot be performed consistently. In mixed-model human–humanoid production, such conditions are especially dangerous. Humanoid robots rely on stable layouts, clear boundaries, and predictable staging to navigate and interact safely. When these conditions are absent, perception errors and unsafe motion become likely.

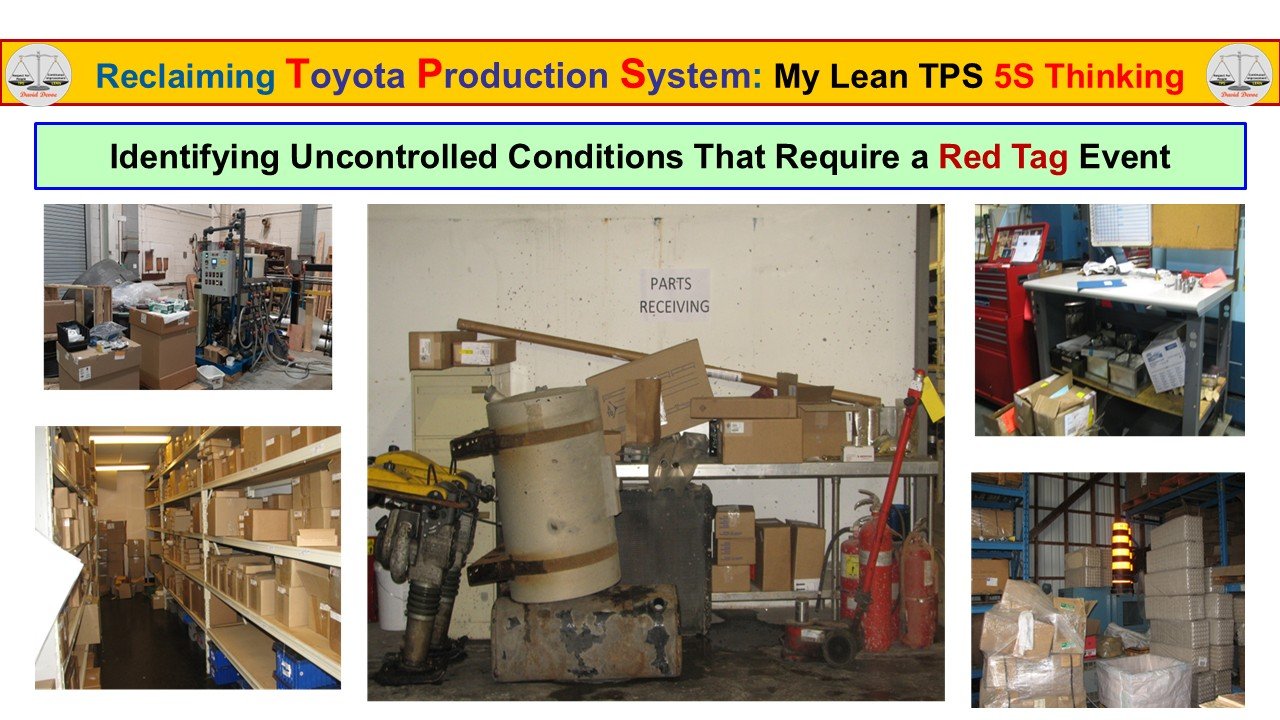

Figure 5: Identifying Uncontrolled Conditions That Require a Red Tag Event

Uncontrolled accumulation of equipment, materials, and inventory creates hidden instability that must be exposed before Quality and safety are compromised.

6. Defining the Elements of 5S Thinking

Recognizing Red Tag Conditions at the Source

A Red Tag Event begins with the ability to recognize instability where it exists. Visual cues such as blocked aisles, mixed materials, overflowing storage, unused equipment occupying prime space, and ad hoc staging areas all indicate loss of control. These conditions signal that decisions about what belongs in the workplace have not been made explicitly. Instead, items remain by default. Lean TPS treats this as a failure of the system, not of individual behavior.

By identifying these uncontrolled conditions, Red Tagging converts vague discomfort into actionable information. Items are no longer described as inconvenient or messy. They are identified as not supporting current work. This distinction is critical. It allows teams to separate what is required to produce Quality today from what is historical, speculative, or obsolete. Once identified, these items can be evaluated, relocated, or removed based on evidence rather than habit.

From a Quality perspective, exposing uncontrolled conditions restores the ability to detect abnormality. With excess items removed or isolated, deviations in equipment condition, material quality, and work execution become immediately visible. From a safety perspective, Red Tag identification clears paths of travel, reduces collision risk, and restores defined zones for people and machines. For humanoid robots, this process establishes the clean spatial envelope required for reliable navigation, accurate perception, and safe interaction.

Identifying uncontrolled conditions is therefore not an audit activity. It is an act of system recovery. It reasserts control over the environment and prepares the workplace for deliberate decisions about layout, material presentation, and flow.

Clarifying Meaning to Prevent Superficial Application

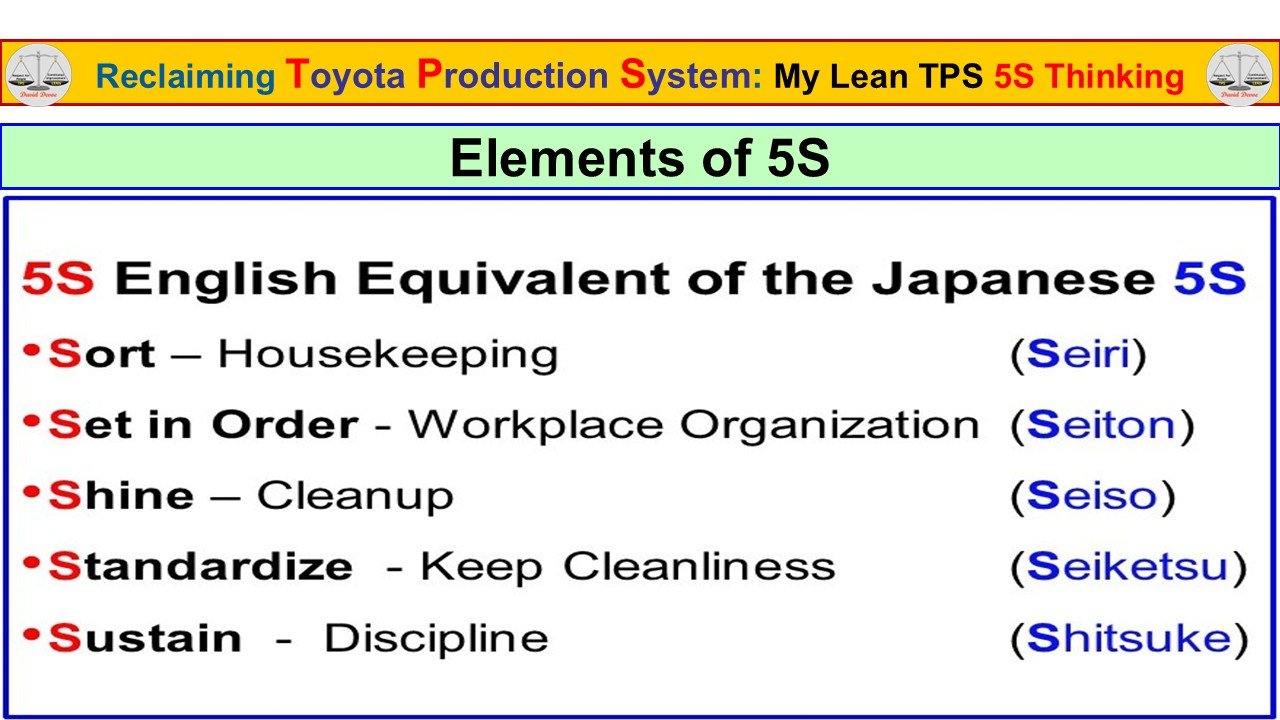

5S Thinking is often weakened when its elements are reduced to simplified translations or treated as housekeeping terms. In Lean TPS, the five elements are not labels for activities. They are precise definitions that describe how stability is created and maintained in the workplace. When these elements are misunderstood, 5S degrades into cosmetic cleanup, short-lived events, or compliance exercises that fail to protect Quality or sustain control. Clear definition is therefore required before execution.

The Japanese terms behind 5S describe intent, not appearance. Each element addresses a specific source of environmental variation that interferes with consistent work. When organizations rely on loose or inaccurate interpretations, the system loses discipline and the sequence collapses. In mixed-model human–humanoid production, this loss of precision has immediate consequences. Humanoid robots require unambiguous conditions. Vague standards and inconsistent interpretation introduce risk, reduce reliability, and undermine safe collaboration.

Figure 6: Elements of 5S

The five elements define the specific actions required to create and sustain a stable, controlled workplace.

Using Precise Definitions to Protect Quality

Sort defines the decision process for separating what is required from what is not. It is not housekeeping. It is a deliberate act of exclusion that limits the workplace to items that directly support current work. This definition prevents accumulation and restores visibility.

Set in Order defines exact location, orientation, and quantity. It is not general organization. It establishes fixed relationships between people, tools, materials, and equipment so work begins from a known condition every time.

Shine defines restoration of condition through cleaning as inspection. It is not cleanup. It ensures that deterioration, leakage, wear, and contamination are exposed early, protecting Quality at the source.

Standardize defines how the first three elements are maintained consistently. It is not documentation for its own sake. It establishes repeatable routines, clear ownership, and confirmation that conditions remain within defined limits.

Sustain defines the leadership discipline required to prevent regression. It is not personal motivation. It is the system of observation, coaching, and accountability that ensures stability is preserved under daily pressure.

When the elements of 5S are defined and applied with this level of precision, the workplace becomes predictable and transparent. Abnormalities stand out immediately. Flow stabilizes. Quality is protected before work begins. For humanoid robots, these definitions create the clear, repeatable environment required for accurate perception and safe execution. Defining the elements correctly is therefore not instructional detail. It is a prerequisite for 5S Thinking to function as a Lean TPS system rather than as a set of isolated activities.

7. Restoring Workplace Control Through Visual Standards

Making the Difference Between Normal and Abnormal Obvious

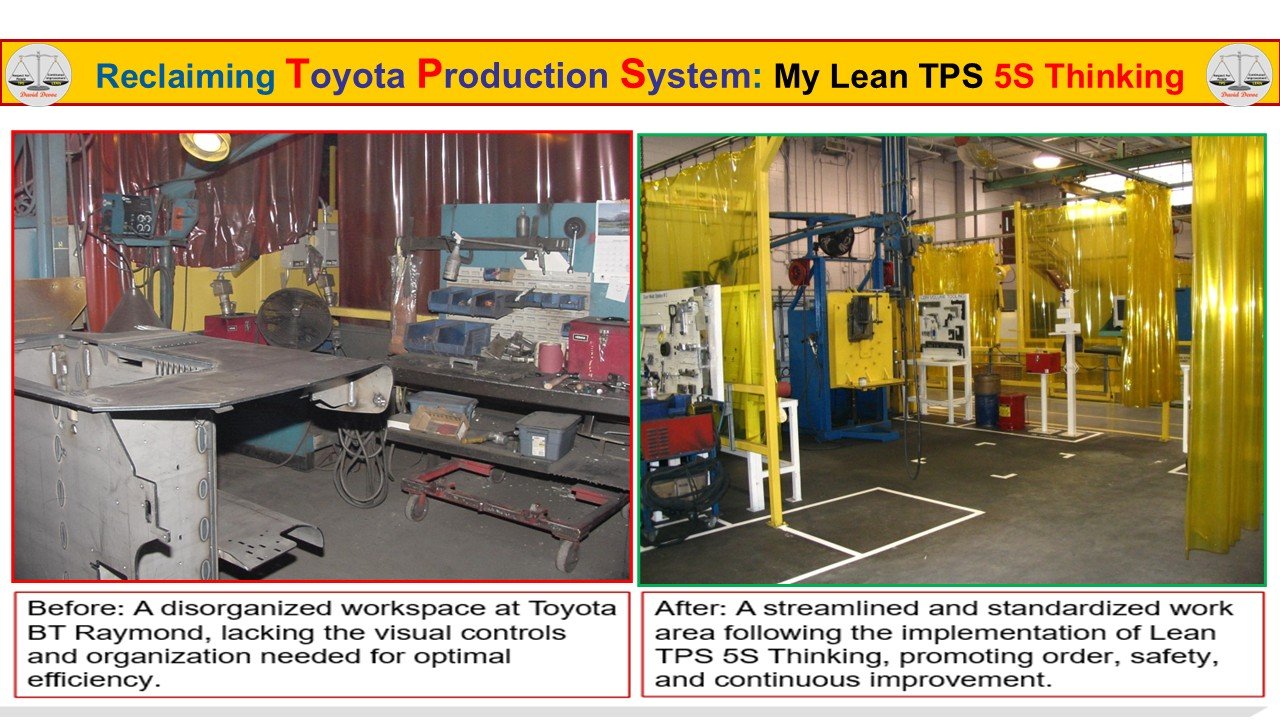

Workplace instability often persists because the difference between normal and abnormal conditions is unclear. When locations are undefined, boundaries are implicit, and storage is informal, disorder blends into daily work and becomes accepted. People adapt to the environment instead of correcting it. Over time, this adaptation erodes Quality, hides emerging problems, and creates dependence on individual judgment rather than system control. Lean TPS 5S Thinking addresses this failure by restoring workplace control through explicit visual standards.

In an uncontrolled environment, time is lost searching for tools, materials are staged wherever space is available, and equipment condition varies from shift to shift. These variations introduce inconsistency before work begins. Leaders cannot see whether work is being performed under normal conditions, and teams cannot detect abnormality without stopping production. In mixed-model human–humanoid production, such ambiguity is unacceptable. Humanoid robots require clear boundaries, fixed locations, and stable spatial references to operate safely. When these references are missing or inconsistent, risk increases immediately.

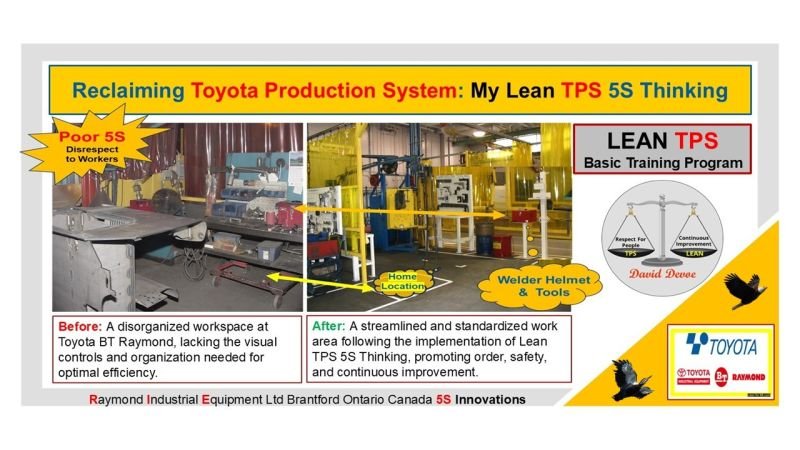

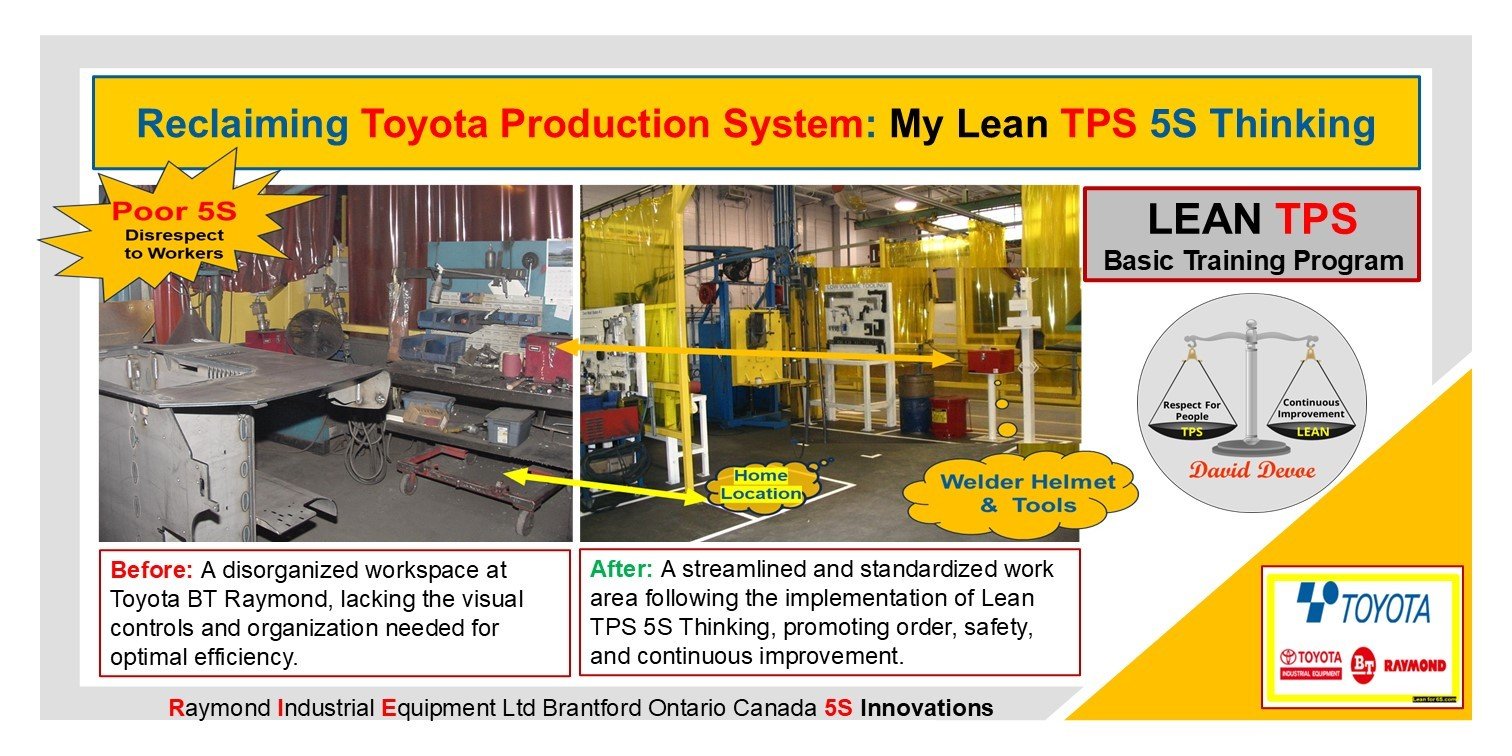

Figure 7: Before and After Workplace Control Using Lean TPS 5S Thinking

A visually controlled workplace makes normal conditions clear, exposes abnormalities immediately, and protects Quality through environmental stability.

Using Visual Control to Protect Quality at the Source

Visual standards convert the workplace itself into a control mechanism. Defined locations, marked boundaries, clear storage limits, and consistent presentation make it immediately obvious when something is missing, misplaced, or out of condition. This clarity reduces reliance on memory, experience, or personal judgment. Instead, the environment communicates the expected condition continuously.

In the controlled workplace, tools return to defined positions, materials are staged within visible limits, and equipment occupies clearly designated space. These conditions stabilize motion paths, reduce searching, and support predictable work execution. Abnormalities such as missing tools, excess inventory, or misaligned equipment stand out instantly. This immediate visibility allows problems to be addressed before they affect Quality or disrupt flow.

From a safety perspective, visual control establishes clear paths of travel and defined work zones, reducing collision risk for both people and machines. For humanoid robots, these visual standards provide the fixed references required for accurate perception, navigation, and task execution. Stable visual cues enable robots to distinguish work areas, identify objects reliably, and interact with humans without ambiguity.

Restoring workplace control through visual standards is not an aesthetic exercise. It is a Quality protection mechanism. By making normal conditions explicit and abnormalities unmistakable, Lean TPS 5S Thinking ensures that problems are exposed at the source and addressed before they propagate. This discipline transforms the workplace from a variable environment into a predictable system that supports consistent human performance and safe, reliable human–humanoid collaboration.

8. Using the A3 to Structure 5S Thinking as a System

Turning 5S from Activities into Shared Understanding

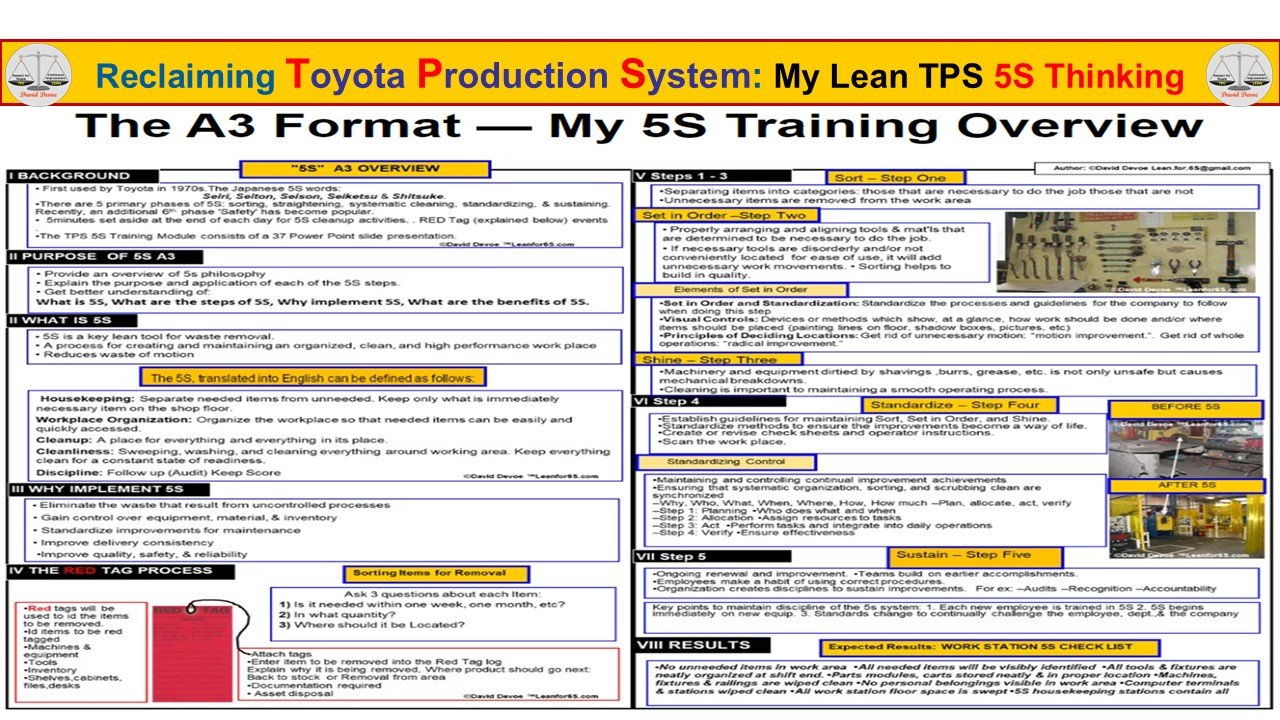

5S Thinking loses effectiveness when it is taught as a list of steps without structure or context. Teams may remember the sequence, but they do not understand how the elements connect, why decisions are made, or how stability is sustained over time. In Lean TPS, this gap is addressed by using the A3 format to organize thinking, not just to document results. The A3 provides a single, coherent structure that links purpose, conditions, actions, and outcomes into a shared system view.

Without a structured way to explain 5S, organizations fall back on fragmented training. Sort is taught separately from Set in Order. Cleaning is emphasized without connection to inspection. Standardization becomes paperwork. Sustain becomes reminders and audits. This fragmentation weakens Quality because people execute tasks without understanding how those tasks protect the system. In mixed-model human–humanoid environments, this lack of shared understanding increases risk. Humans may improvise based on experience. Humanoid robots depend on stable, explicitly defined conditions that must be designed intentionally.

Figure 8: A3 Format for 5S Thinking

The A3 organizes 5S Thinking into a single system view that connects purpose, conditions, actions, and results.

Using the A3 to Align Purpose, Conditions, and Results

The A3 format forces clarity. It begins by defining the purpose of 5S Thinking as a Quality system, not as housekeeping or waste removal alone. It then links each step of 5S to a specific condition that must be created or restored in the workplace. This makes the logic visible. Sort removes what does not support current work. Set in Order establishes fixed relationships. Shine restores condition through inspection. Standardize locks control into routine. Sustain ensures discipline over time. Each step exists for a reason, and the A3 makes those reasons explicit.

By placing the entire 5S system on a single page, the A3 prevents selective implementation. Teams can see immediately if a step has been skipped, rushed, or diluted. Leaders can verify whether the workplace conditions actually match the intended design. This visibility supports coaching, problem solving, and consistent deployment across areas. It also prevents 5S from becoming dependent on individual champions or isolated events.

From a Quality perspective, the A3 ensures that improvements are not disconnected from outcomes. Conditions are linked directly to results such as abnormality detection, stable flow, and safe operation. For humanoid robots, this structured clarity is essential. The A3-driven approach ensures that environmental conditions are defined, maintained, and verified consistently, providing the predictability required for reliable perception and safe interaction.

Using the A3 to structure 5S Thinking transforms training into system design. It aligns teams around a common understanding of why each element exists and how they work together to protect Quality. This discipline turns 5S from a collection of activities into a coherent Lean TPS system that can be taught, sustained, and scaled without loss of intent.

9. Using Evaluation to Confirm and Sustain 5S Conditions

Verifying Workplace Stability Through Observable Criteria

5S Thinking cannot be sustained through intention or awareness alone. Stability must be verified continuously through direct observation of workplace conditions. In Lean TPS, evaluation is not used to judge people or assign scores for compliance. It is used to confirm whether the environment continues to meet the conditions required to protect Quality, support flow, and expose abnormality. Without a clear method to evaluate 5S conditions, deterioration occurs gradually and remains unnoticed until problems surface downstream.

Evaluation criteria translate 5S Thinking from concept into observable reality. They define what stable conditions look like in daily work and provide a common reference for teams and leaders. When criteria are vague or inconsistent, evaluation becomes subjective and loses credibility. In mixed-model human–humanoid production, this ambiguity creates risk. Humanoid robots depend on stable layouts, clear paths, clean surfaces, and defined storage to operate safely. If these conditions are not verified routinely, reliability degrades and safety margins erode.

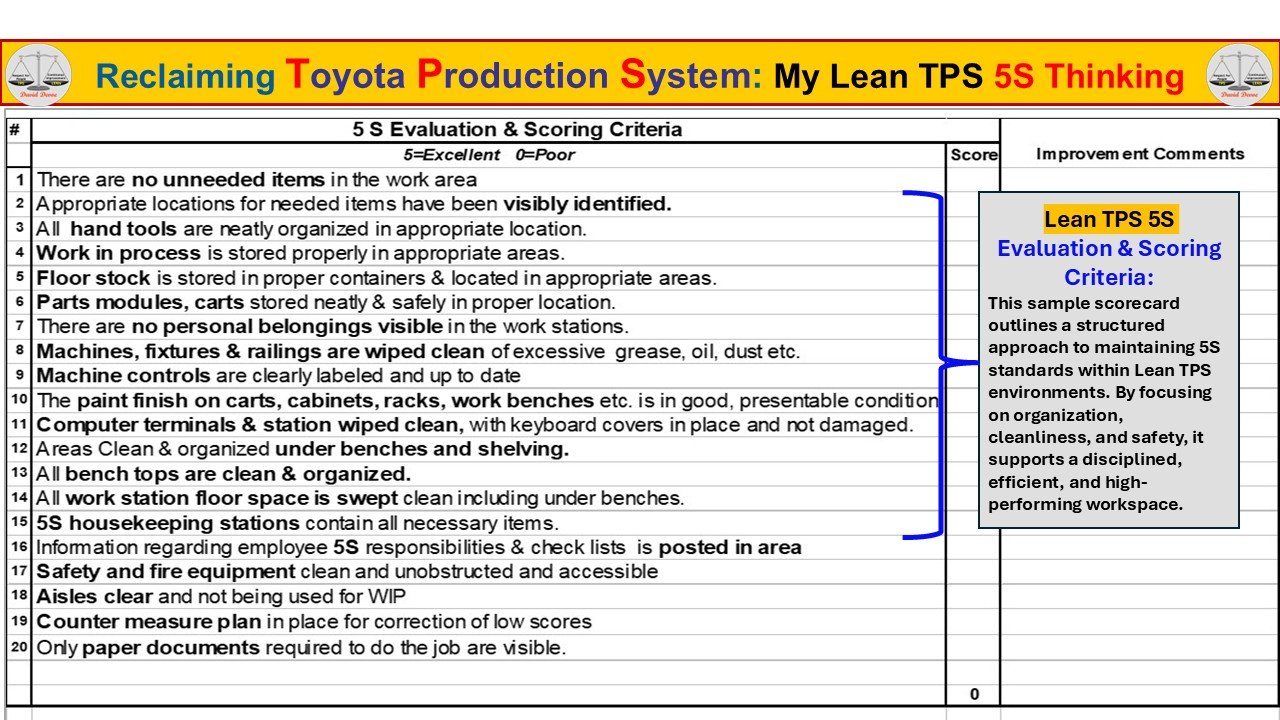

Figure 9: Lean TPS 5S Evaluation and Scoring Criteria

A structured evaluation checklist defines the observable conditions required to maintain 5S stability and protect Quality.

Using Evaluation to Prevent Drift and Protect Quality

Effective 5S evaluation focuses on conditions, not behavior. It asks whether unnecessary items are absent, whether locations are clearly defined, whether materials are stored within limits, and whether cleanliness reveals equipment condition. These checks confirm that the environment supports consistent work execution. They also make deterioration visible early, when correction is simple and low risk.

Evaluation criteria serve as an early warning system. Low scores or recurring findings indicate loss of control, not individual failure. This allows teams to respond with corrective action before instability affects Quality or delivery. Leaders use evaluation results to prioritize support, remove barriers, and reinforce standards through coaching rather than enforcement.

From a Quality perspective, structured evaluation ensures that abnormalities are detected at the source. From a safety perspective, it confirms that aisles remain clear, equipment is accessible, and hazards are controlled. For humanoid robots, evaluation verifies that spatial references, boundaries, and staging areas remain consistent with the environment assumed by control systems and perception algorithms.

When evaluation is applied consistently, 5S Thinking becomes self-correcting. Drift is identified quickly, countermeasures are applied deliberately, and stability is restored before problems propagate. Evaluation is therefore not an administrative layer added to 5S. It is a necessary mechanism for sustaining environmental control and ensuring that the conditions required for Quality, flow, and safe human–humanoid collaboration remain intact every day.

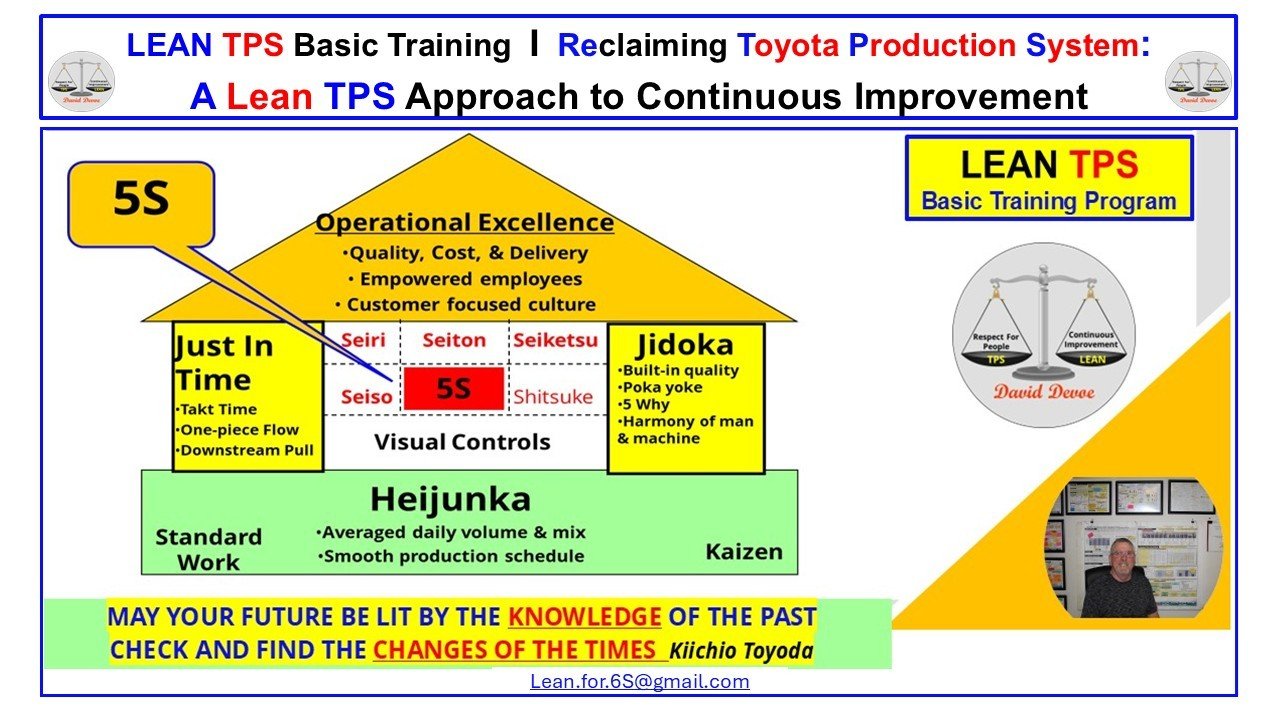

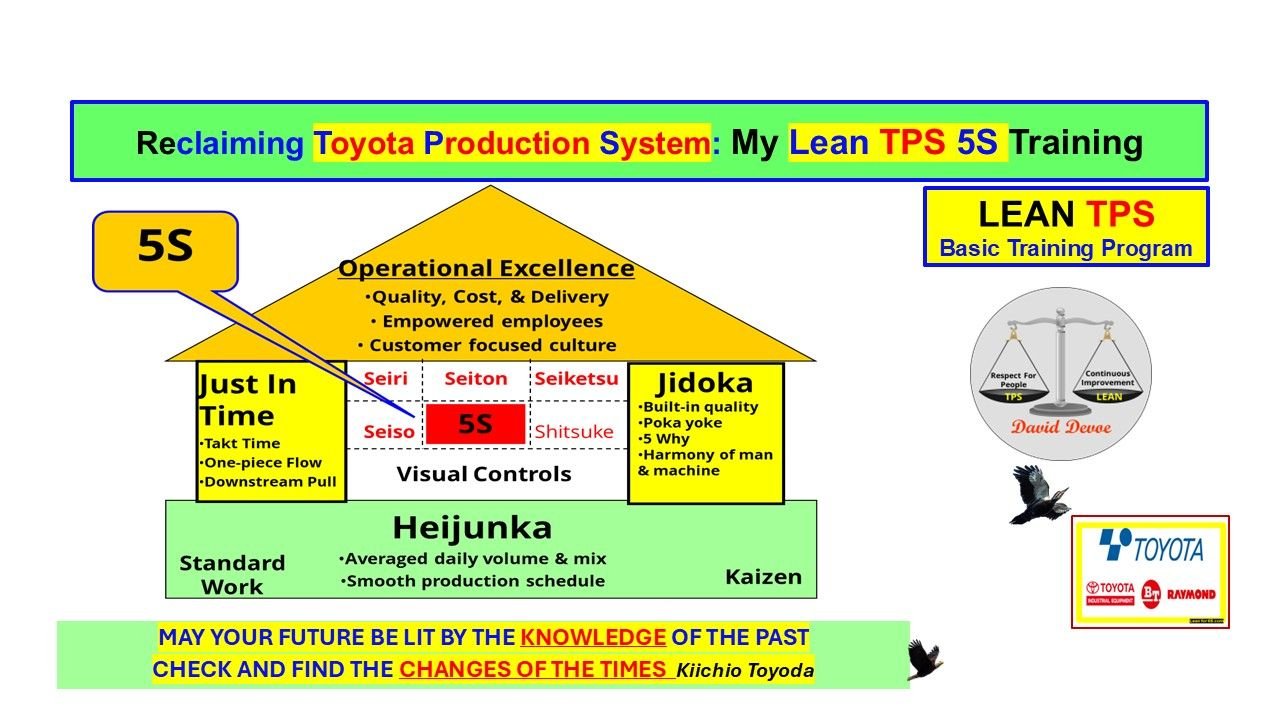

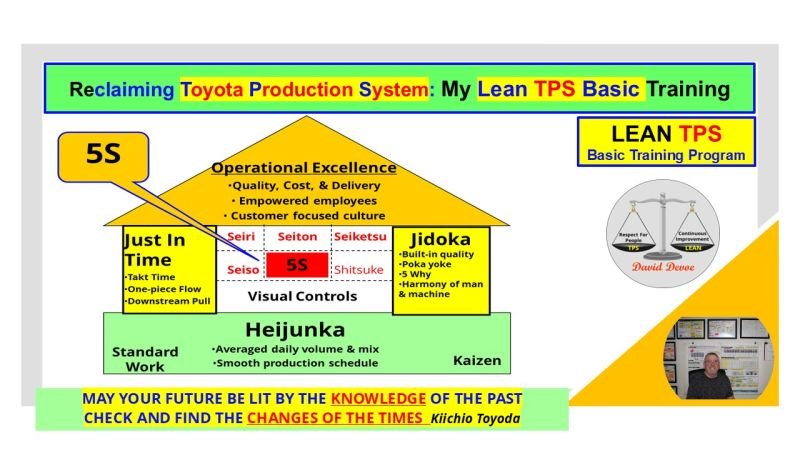

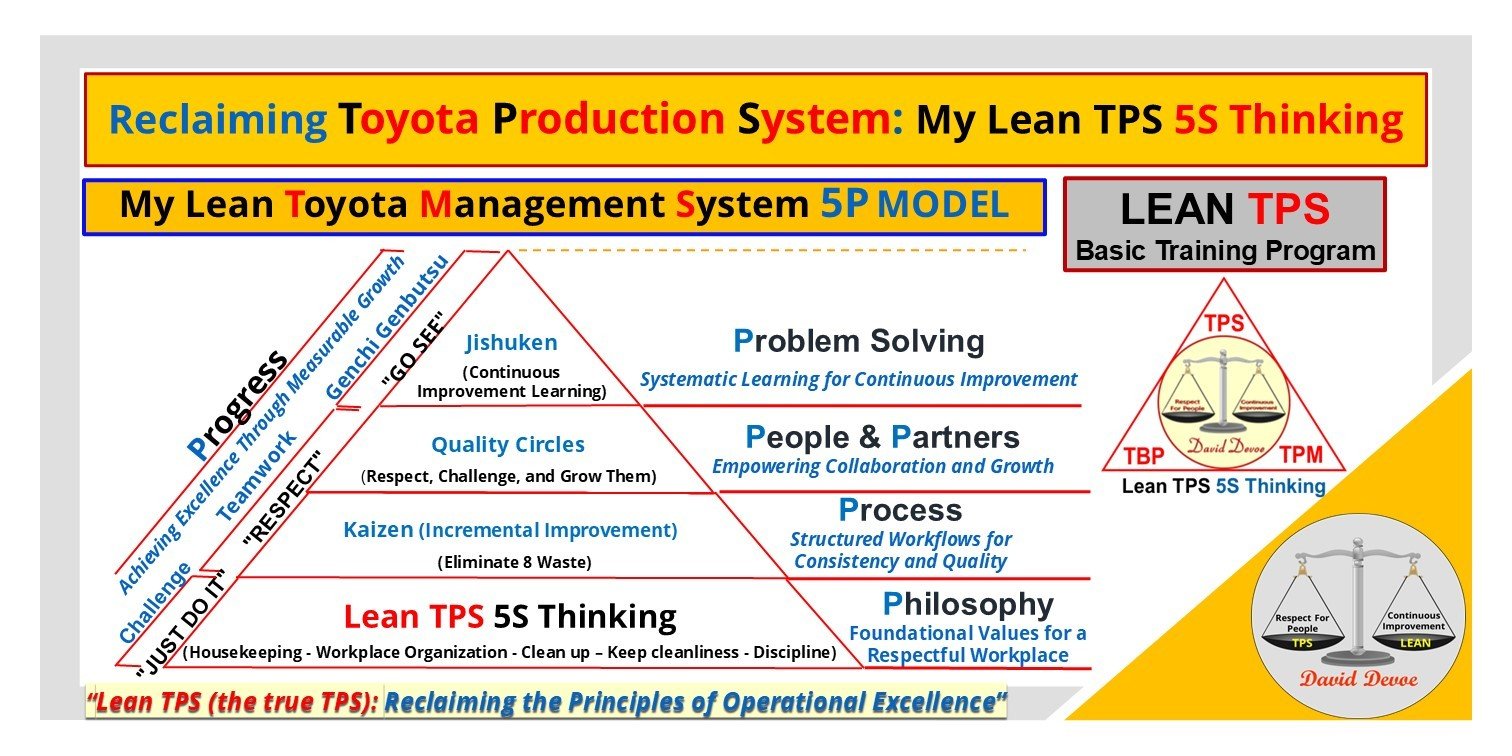

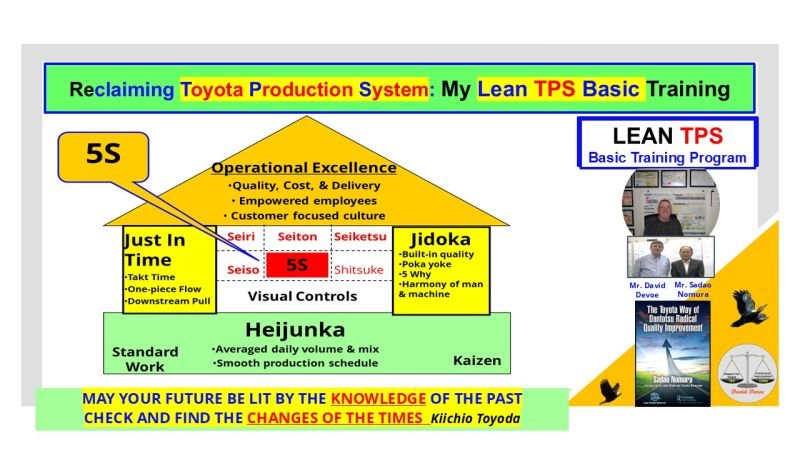

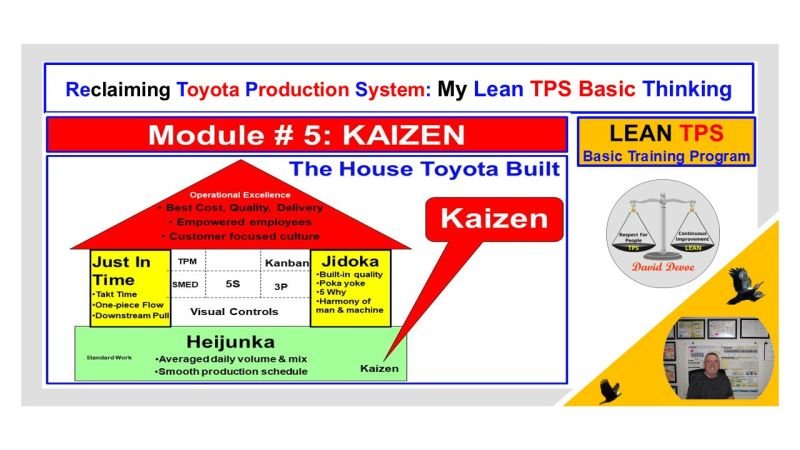

10. Positioning 5S at the Center of the Toyota Production System

5S as the Structural Link Between Stability, Flow, and Built-In Quality

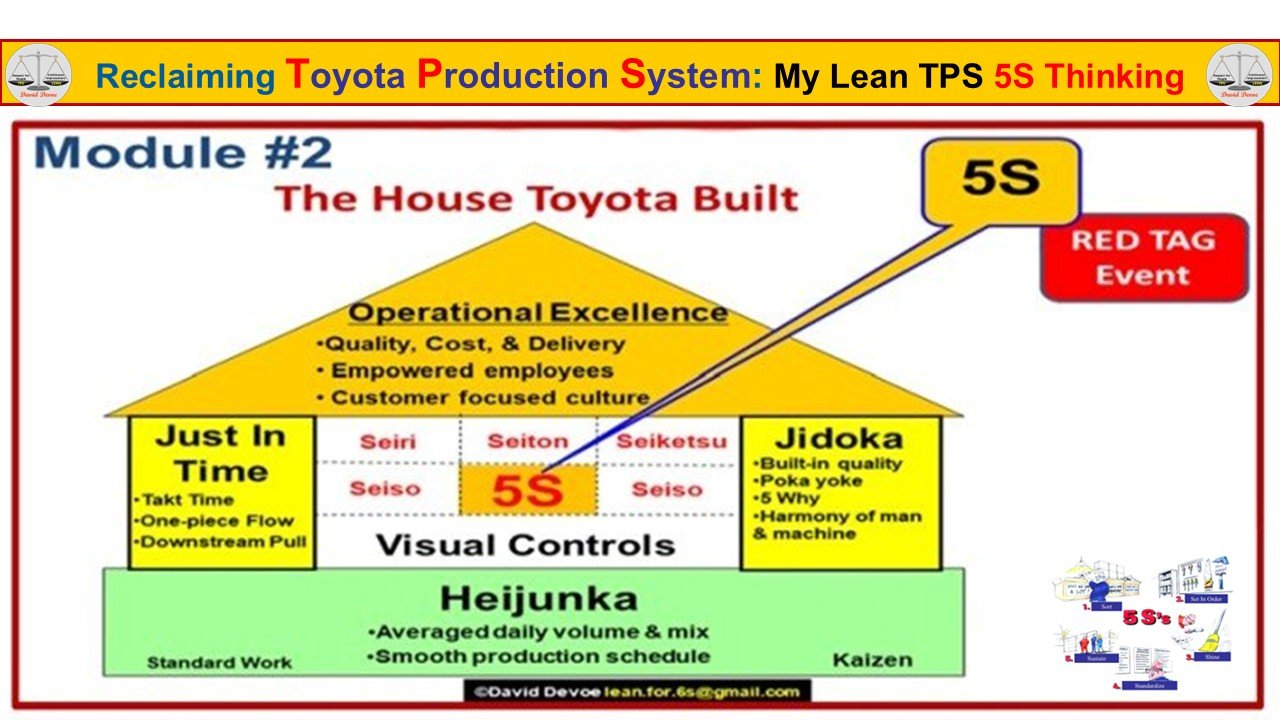

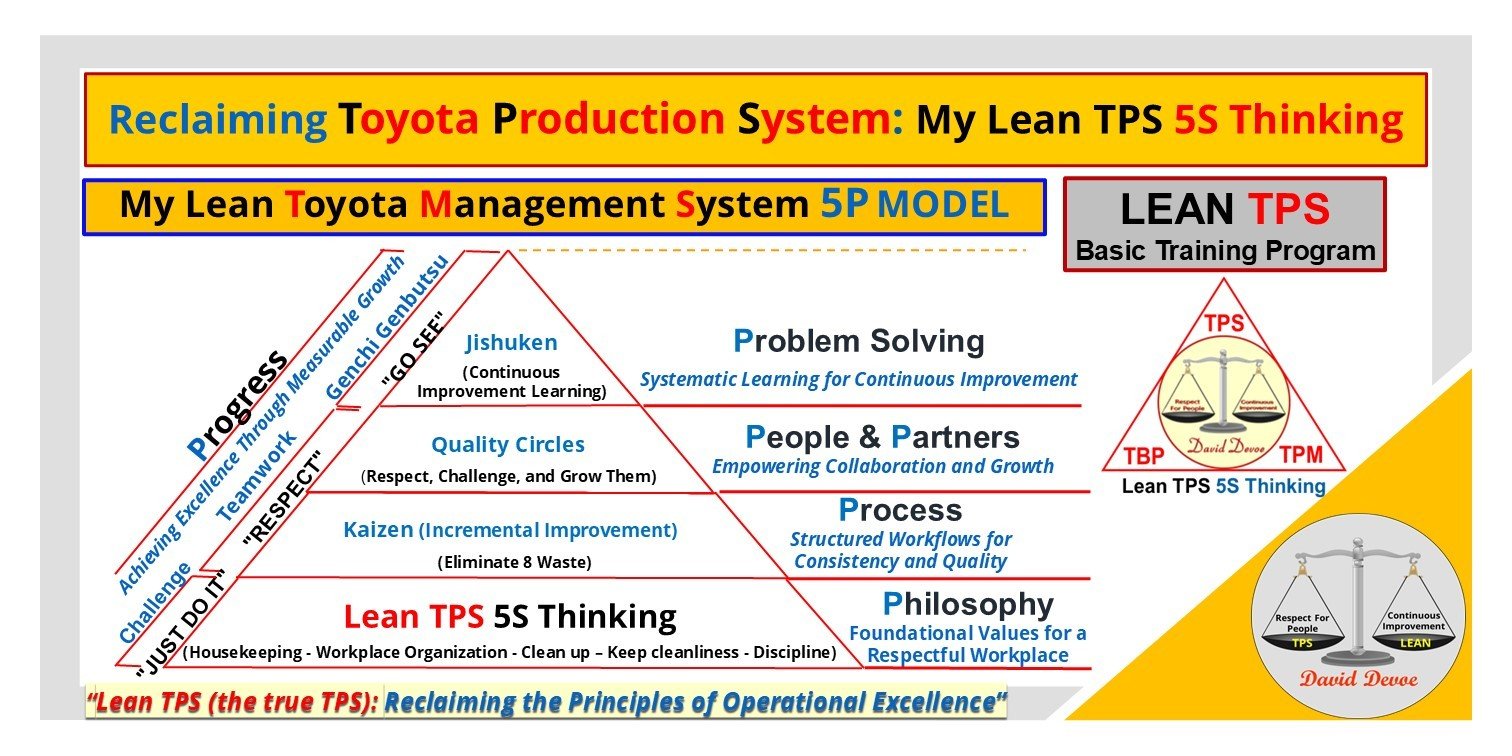

5S Thinking occupies a central position within the Toyota Production System because it creates the environmental stability required for every other element to function. It is not an isolated program layered onto TPS. It is the mechanism that connects daily work conditions to system performance. By controlling the physical and visual environment, 5S enables Just In Time, Jidoka, and Heijunka to operate as intended rather than as abstract concepts.

Within the TPS structure, 5S supports both pillars. Just In Time depends on predictable flow, defined locations, and clear material presentation. Without 5S, takt adherence breaks down, one-piece flow is disrupted, and downstream pull becomes unreliable. Jidoka depends on immediate detection of abnormality. Without stable, visible conditions, defects, equipment deterioration, and process variation remain hidden until they cause failure. 5S establishes the baseline that allows both pillars to function at the source.

Figure 10: 5S at the Center of the Toyota Production System

5S Thinking provides the environmental stability that enables Just In Time, Jidoka, and Heijunka to function as an integrated system.

Enabling System Behavior Through Environmental Control

The TPS house illustrates that system behavior is built on foundational conditions. Visual control, standardized placement, and disciplined restoration of condition allow work to be executed consistently across shifts and models. When these conditions are present, leaders can see problems immediately, teams can respond before defects propagate, and flow can be leveled and sustained.

From a Quality perspective, 5S ensures that defects are not created by environmental variation. Tools are where they are expected to be. Materials are presented correctly. Equipment condition is visible. These conditions prevent errors before they occur and support built-in Quality rather than inspection after the fact.

In mixed-model human–humanoid production, the central role of 5S becomes even more critical. Humanoid robots assume that the environment matches its defined state. Any deviation in layout, staging, or visual reference introduces risk. By positioning 5S at the center of the system, Lean TPS ensures that the workplace itself supports reliable perception, safe motion, and predictable interaction between humans and robots.

5S Thinking is therefore not preparatory work that can be rushed or delegated. It is the structural discipline that anchors the Toyota Production System in reality. When 5S is strong, the system behaves as designed. When it is weak, even well-designed processes degrade. Positioning 5S at the center ensures that stability, flow, and Quality remain aligned every day.

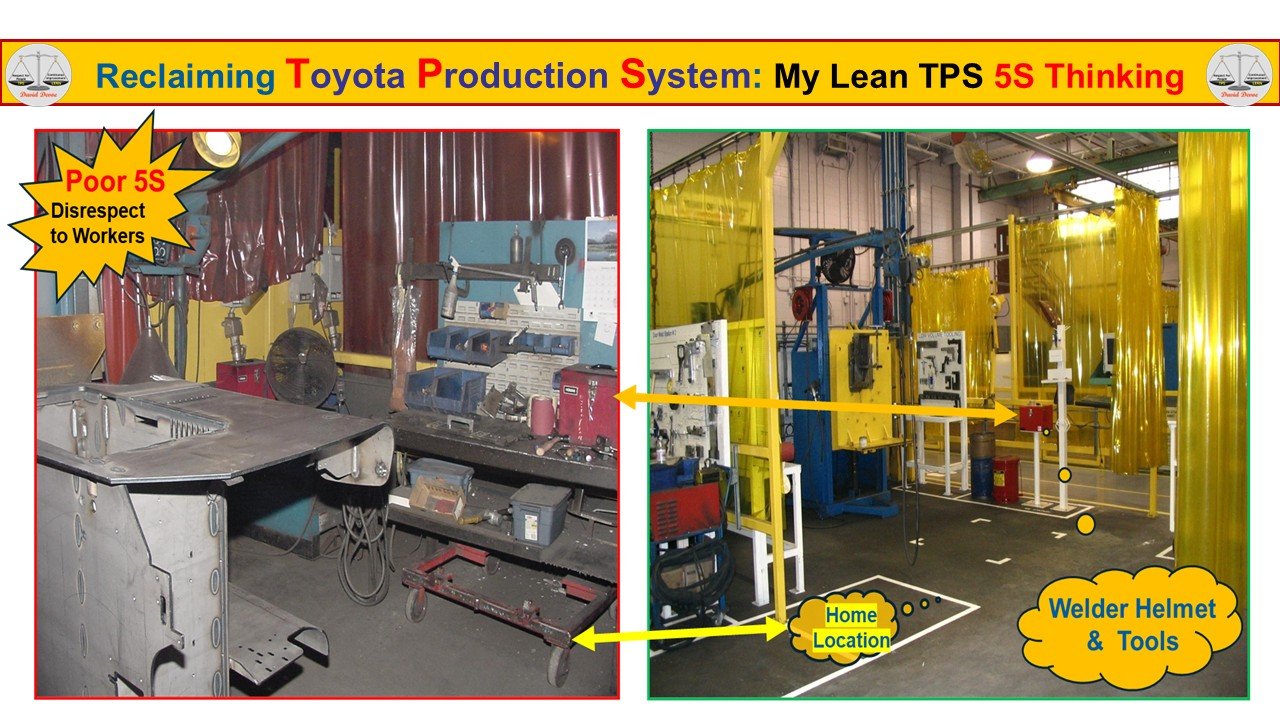

11. Demonstrating Respect Through Stable Workplace Design

How 5S Conditions Signal Expectations and Protect Quality

The condition of the workplace communicates expectations more clearly than any written policy. When work areas are cluttered, disorganized, or allowed to drift, the system signals that instability is acceptable and that people are expected to compensate. This places unnecessary burden on workers, increases variation, and degrades Quality. In Lean TPS, this is treated as a failure of system design, not of individual behavior. 5S Thinking restores respect by creating environments where people can perform work correctly without improvisation or unnecessary effort.

A poorly controlled workplace forces workers to search for tools, navigate obstacles, and work around hazards. These conditions consume attention and energy that should be applied to producing Quality. They also hide abnormality. When everything is out of place, nothing stands out. Leaders lose the ability to see problems, and corrective action is delayed. In mixed-model human–humanoid production, these conditions create immediate risk. Humanoid robots cannot interpret ambiguous layouts or compensate for missing or misplaced items. Instability becomes a safety issue as well as a Quality issue.

Figure 11: Workplace Conditions Before and After 5S Thinking

Clear locations, visual boundaries, and defined standards demonstrate respect for workers and create the stability required for Quality and safe operation.

Respect as a Function of Environmental Control

Respect in Lean TPS is expressed through design. When tools have defined home locations, when personal protective equipment is staged correctly, and when work zones are clearly marked, the system supports correct behavior without instruction. Workers are not forced to remember where items belong or negotiate space each shift. The environment itself reinforces the standard.

Stable workplace design also protects dignity. Clean, organized areas communicate that work is valued and that Quality matters. This encourages adherence to standards and reduces frustration. For humanoid robots, these same conditions provide the fixed references required for reliable perception and safe movement. Clear boundaries and consistent staging allow robots to operate predictably alongside people without conflict or confusion.

From a Quality perspective, stable design prevents errors caused by missing tools, incorrect setup, or environmental distraction. From a safety perspective, it reduces collision risk and ensures that protective equipment is accessible and used as intended. These outcomes are not the result of motivation or enforcement. They are the result of deliberate environmental control.

5S Thinking therefore functions as a visible expression of respect. It removes unnecessary obstacles, reduces cognitive load, and creates conditions where people and humanoid robots can perform work as designed. By stabilizing the environment, Lean TPS protects Quality at the source and establishes a workplace where expectations are clear and consistently met.

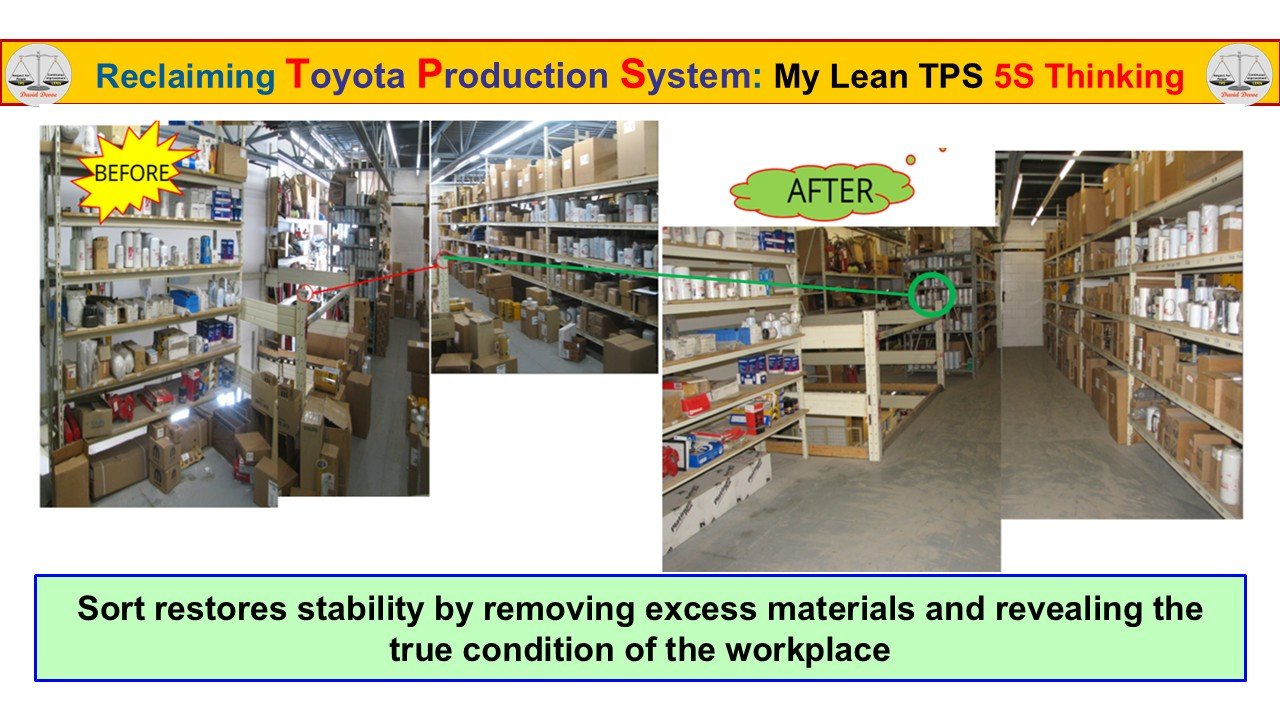

12. Restoring Flow and Visibility Through Sorting Excess Material

Revealing the True Condition of the Workplace

Excess material distorts the true condition of the workplace. When shelves are overfilled, aisles are narrowed, and inventory is staged without clear limits, the environment absorbs variation and hides problems. Flow appears constrained, but the root cause is not demand or capacity. It is loss of control. Lean TPS 5S Thinking uses Sort to remove this distortion and restore visibility so the real condition of the process can be observed and addressed.

In environments with excess material, movement becomes indirect and unpredictable. People detour around obstacles, carts are parked wherever space is available, and material is handled multiple times before use. These conditions introduce motion waste, increase handling damage, and delay detection of shortages or defects. Leaders cannot distinguish between normal and abnormal inventory levels because everything looks full. In mixed-model human–humanoid production, this lack of clarity creates immediate risk. Humanoid robots require defined aisles, clear staging zones, and consistent inventory presentation to navigate safely and execute tasks accurately.

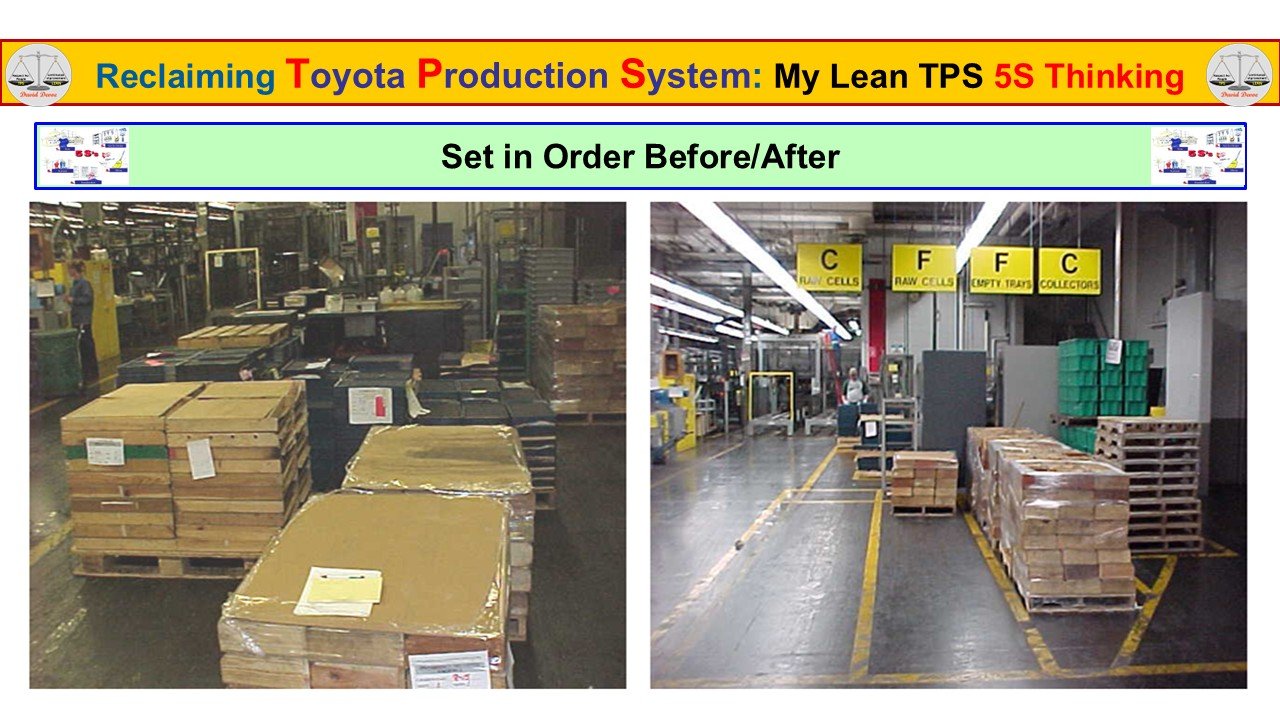

Figure 12: Sort Restores Stability by Removing Excess Materials

Removing excess inventory reveals the true condition of the workplace, restores flow, and makes abnormal conditions visible.

Using Sort to Protect Quality and Enable Flow

Sorting excess material is not about reducing inventory arbitrarily. It is about aligning material presence with actual production requirements. By removing items that do not support current demand, the workplace regains space, clarity, and predictability. Aisles become passable, storage locations become visible, and material levels can be evaluated against defined standards rather than guesswork.

From a Quality perspective, this clarity prevents damage caused by overstacking, improper storage, and repeated handling. It also exposes quality issues sooner. Defective or obsolete material no longer disappears into crowded shelves. Abnormal conditions stand out and trigger corrective action. From a flow perspective, defined paths and controlled staging reduce delays and support smooth material movement.

For humanoid robots, the benefits are decisive. Clear aisles and defined storage zones provide the fixed spatial references required for reliable navigation and collision avoidance. Consistent material presentation supports accurate recognition and handling. When excess material is removed, the environment aligns with the assumptions built into robotic perception and control systems.

Sorting excess material restores the workplace to a state where flow can occur and Quality can be protected. It replaces congestion with control and replaces hidden variation with visible conditions. This step is essential for transforming storage areas from passive accumulation zones into active components of a stable, predictable production system.

13. Using Shine to Restore Equipment Condition and Process Readiness

Cleaning as Inspection to Protect Quality

Shine is often misunderstood as an aesthetic activity, but in Lean TPS it is a method for restoring and confirming equipment condition. Cleaning is performed to expose abnormalities, not to improve appearance. Dirt, oil, residue, and clutter hide deterioration, leaks, looseness, and wear that directly affect Quality and reliability. Shine removes these masks so the true condition of equipment and the surrounding environment can be observed and addressed.

When areas are not cleaned routinely, problems accumulate silently. Small leaks become large failures. Wear progresses unnoticed. Temporary fixes become permanent. In such environments, work is performed under degraded conditions, and Quality depends on operator compensation rather than system stability. In mixed-model human–humanoid production, this degradation creates immediate risk. Humanoid robots rely on clean surfaces, clear visual references, and predictable physical interfaces. Contamination and disorder interfere with perception and motion, increasing the likelihood of error or unsafe interaction.

Figure 13: Before Sort and After Shine Inspection Cleaning

Shine restores visibility, reveals equipment condition, and reestablishes a work environment that supports Quality and continuous improvement.

Restoring Readiness Through Environmental Discipline

Shine establishes readiness by returning the workplace to a known condition. Equipment surfaces are cleaned so leaks, cracks, and abnormal wear become visible. Floors are cleared so hazards and contamination are detected immediately. Storage areas are wiped down so material condition can be verified at a glance. This discipline ensures that work begins from a stable baseline every shift.

From a Quality perspective, Shine prevents defects caused by contamination, equipment failure, and undetected deterioration. From a safety perspective, it reduces slip hazards, fire risk, and exposure to unsafe conditions. For humanoid robots, Shine ensures that sensors receive accurate visual input and that movement paths remain unobstructed and predictable.

Shine also reinforces respect for people. A clean, orderly environment signals that Quality matters and that the system supports correct work. It reduces frustration, increases confidence, and encourages adherence to standards. When combined with Sort and Set in Order, Shine completes the restoration of environmental control and prepares the workplace for standardization.

Shine is therefore not a periodic cleanup. It is a daily act of inspection that protects Quality at the source and sustains readiness for continuous improvement. By making problems visible early, Shine ensures that instability is addressed before it affects flow, safety, or human–humanoid collaboration.

14. Establishing Set in Order to Eliminate Searching and Variation

Creating Fixed Relationships Between Work, Material, and Space

Set in Order transforms a cleared workplace into a controlled one by defining exactly where items belong, how they are presented, and how much is required. After Sort removes excess, Set in Order prevents disorder from returning by fixing the relationship between people, materials, tools, and equipment. Without this discipline, space is gradually reoccupied based on convenience, and variation re-enters the environment before work begins.

In uncontrolled areas, materials accumulate temporarily and remain indefinitely. Carts are staged wherever space is available. Tools are placed where they were last used rather than where they belong. These conditions create searching, unnecessary motion, and inconsistent task execution. Leaders cannot tell whether the workplace is in a normal condition because there is no defined reference. In mixed-model human–humanoid production, this lack of definition creates immediate risk. Humanoid robots require fixed locations, consistent orientation, and predictable spacing to recognize objects and navigate safely.

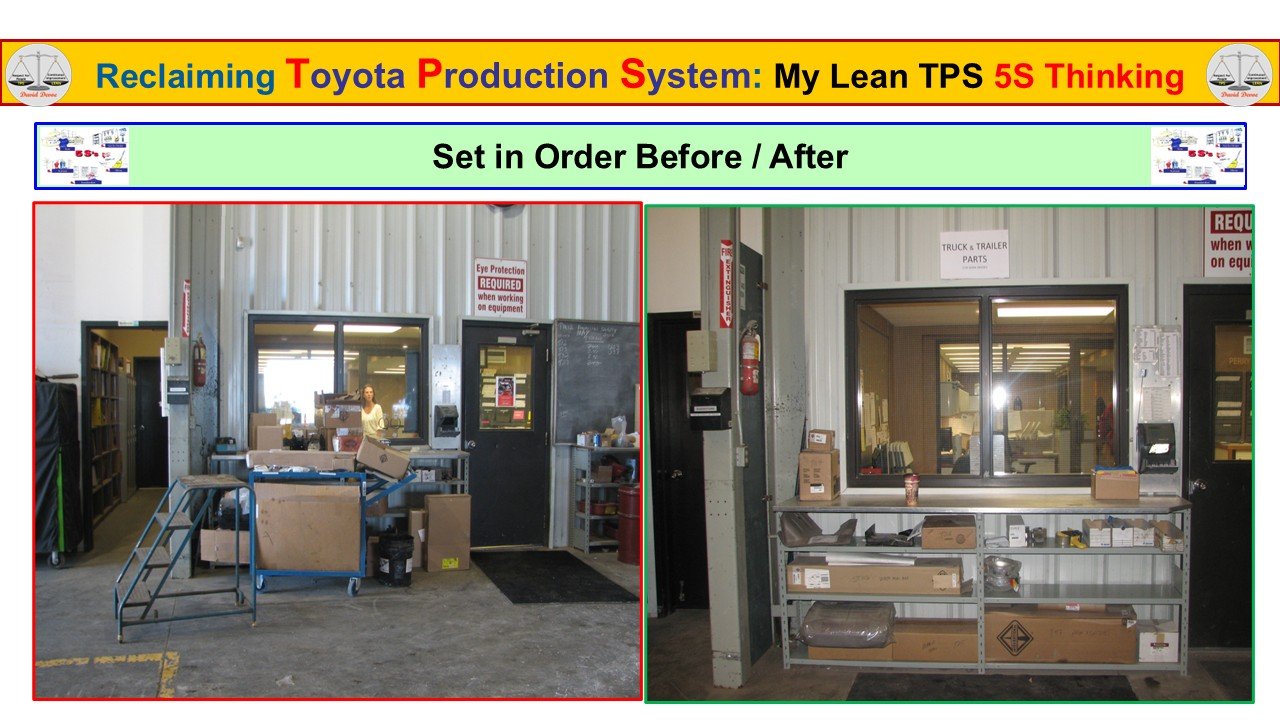

Figure 14: Set in Order Before and After

Defining locations and presentation restores control, reduces motion, and creates a stable environment for Quality and safe operation.

Using Defined Locations to Protect Quality and Flow

Set in Order establishes clear home locations for every required item. Storage is aligned to point of use. Quantities are limited to what is needed for current work. Visual cues such as shelving, labels, and boundaries communicate expected conditions without instruction. When something is missing or out of place, the abnormality is immediately visible.

From a Quality perspective, this clarity prevents errors caused by incorrect parts, missing tools, or inconsistent setup. Work begins from the same condition every cycle, reducing variation and supporting Standardized Work. From a flow perspective, defined locations eliminate searching and reduce handling, allowing work to progress smoothly and predictably.

For humanoid robots, Set in Order is essential system design. Fixed positions and consistent presentation provide the spatial references required for accurate perception and reliable motion planning. When locations drift or staging is informal, robotic systems cannot compensate. Stability must be designed into the environment.

Set in Order is not about neatness. It is about control. By fixing relationships between space, materials, and work, Lean TPS ensures that the environment supports consistent execution, visible abnormality, and protected Quality every day.

15. Defining Material Locations to Stabilize Flow

Preventing Congestion Through Clear Staging and Boundaries

Uncontrolled material staging is one of the fastest ways to disrupt flow and hide instability. When pallets, containers, and work-in-process are placed wherever space is available, aisles narrow, paths shift, and material handling becomes unpredictable. These conditions introduce delay, excess motion, and safety risk before work even begins. Lean TPS 5S Thinking uses Set in Order to prevent this drift by defining where materials belong and where they do not.

In uncontrolled environments, material presence becomes ambiguous. Operators cannot tell whether inventory levels are normal or excessive. Leaders cannot see whether flow is aligned with demand. Temporary staging becomes permanent, and congestion is treated as unavoidable. In mixed-model human–humanoid production, this ambiguity creates immediate risk. Humanoid robots require defined travel paths, clear staging zones, and stable spatial boundaries to navigate safely and coordinate movement with people.

Figure 15: Set in Order Before and After for Material Staging

Defined locations and visual boundaries stabilize material flow, restore aisle clarity, and protect Quality and safety.

Using Location Control to Protect Quality and Safety

Set in Order establishes explicit staging zones for materials based on production needs. Floor markings, signage, and container limits communicate where inventory is permitted and how much is acceptable. When materials exceed these limits, the abnormality is visible immediately. This prevents overproduction, reduces handling, and supports Just In Time flow.

From a Quality perspective, controlled staging prevents damage caused by stacking, congestion, and repeated movement. Materials are stored correctly and accessed consistently, reducing variation at the point of use. From a safety perspective, clear aisles and defined zones reduce collision risk and ensure safe interaction between people, equipment, and robots.

For humanoid robots, location control is essential system design. Fixed staging zones and predictable aisle geometry provide the spatial references required for reliable navigation and collision avoidance. When material placement is disciplined, robotic systems can operate within known boundaries without relying on complex exception handling.

Defining material locations through Set in Order transforms flow from reactive to predictable. It replaces congestion with control and ambiguity with visibility. By stabilizing material placement, Lean TPS protects Quality, supports flow, and creates the conditions required for safe, reliable human–humanoid collaboration.

16. Applying Set in Order at the Point of Use

Designing Tool and Part Presentation for Consistent Work

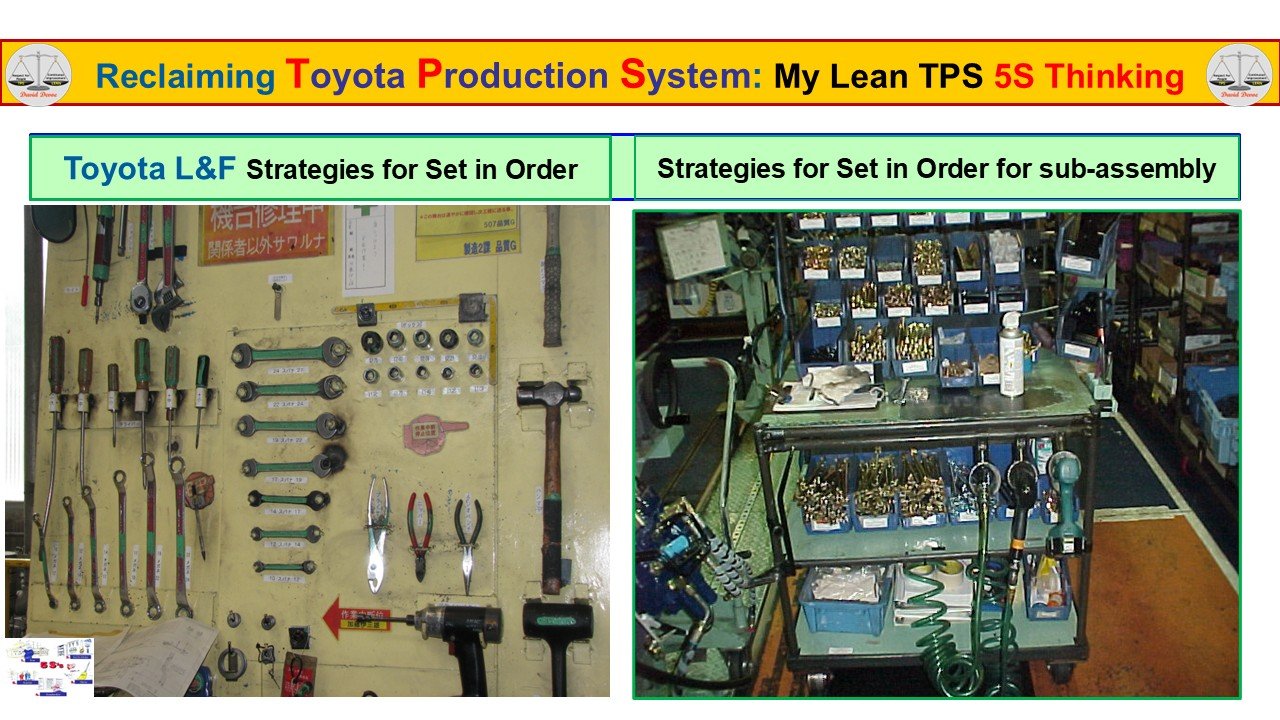

Set in Order reaches its full purpose when tools and parts are positioned exactly where and how they are used. At the point of use, layout decisions directly affect motion, timing, and Quality. When tools are stored generically or parts are grouped without regard to sequence, operators compensate through searching, reaching, and repositioning. These compensations introduce variation into every cycle. Lean TPS 5S Thinking eliminates this variation by designing presentation to match the work.

In Toyota environments, Set in Order is not driven by convenience or personal preference. It is driven by task sequence. Tools are oriented to the hand that uses them. Parts are staged in the order they are consumed. Quantities are limited to what is required for the cycle or short interval. This discipline reduces motion, shortens cycle time, and ensures that work begins from the same physical condition every time. In mixed-model human–humanoid production, this precision is essential. Humanoid robots require fixed positions, consistent orientation, and repeatable access paths to perform tasks reliably.

Figure 16: Toyota Strategies for Set in Order at the Point of Use

Tool and part presentation designed around the work sequence reduces variation, supports Quality, and enables reliable human–humanoid interaction.

Using Presentation Design to Protect Quality

Proper Set in Order design prevents errors before they occur. When tools have defined locations and parts are staged in controlled quantities, missing or incorrect items are immediately visible. This protects Quality by stopping work before defects are created. It also supports Standardized Work by ensuring that each task begins from a known, repeatable condition.

From a flow perspective, point-of-use presentation reduces handling and eliminates unnecessary transport. Operators spend time performing value-added work rather than managing the environment. For humanoid robots, these same conditions provide the spatial certainty required for accurate perception and safe motion. Fixed presentation removes ambiguity and reduces the need for complex sensing or exception handling.

Set in Order at the point of use also reinforces discipline. When every item has a purpose and a place tied directly to the task, deviation is obvious and correction is immediate. This clarity supports coaching, continuous improvement, and stable system behavior.

Applying Set in Order at the point of use transforms workstations from storage areas into controlled execution zones. By aligning presentation with task requirements, Lean TPS creates the conditions required for consistent Quality, predictable flow, and safe collaboration between humans and humanoid robots.

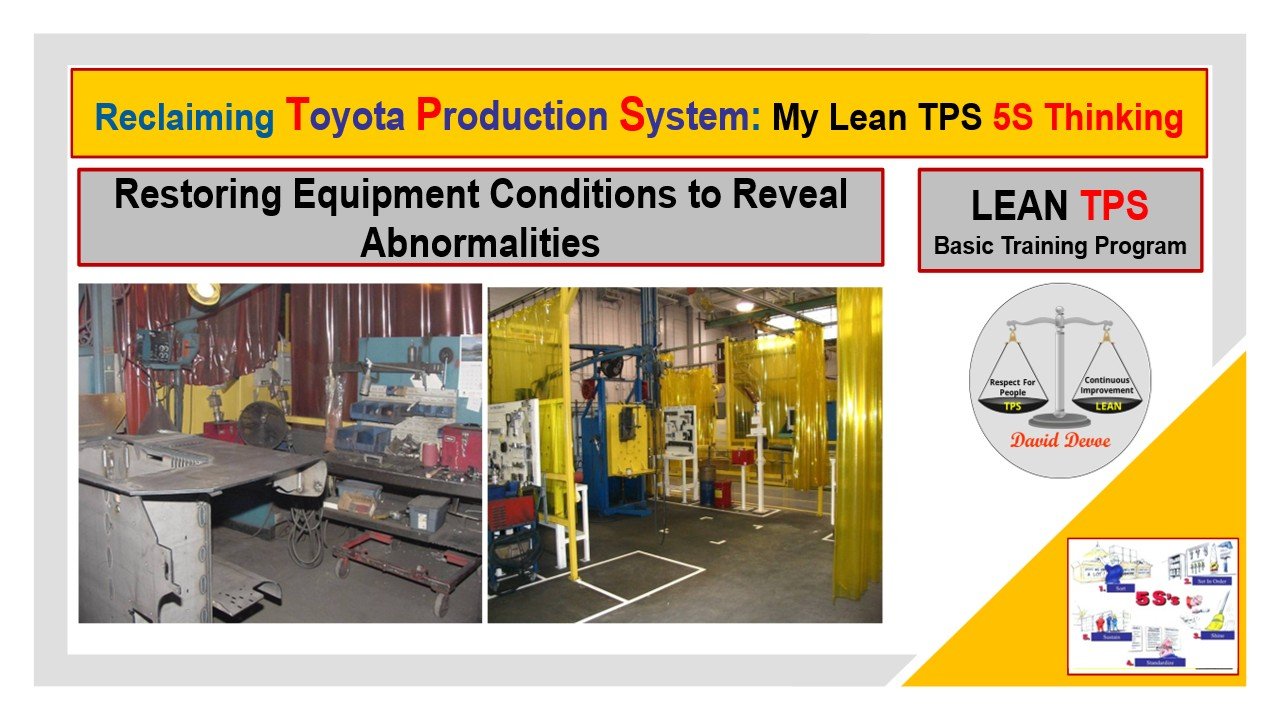

17. Restoring Equipment Conditions to Reveal Abnormalities

Making Equipment Health Visible Through 5S Discipline

Equipment cannot communicate its condition when it is covered by dirt, clutter, or unmanaged attachments. When surfaces are obscured and access is restricted, deterioration progresses unnoticed and failures appear sudden. Lean TPS 5S Thinking restores equipment conditions so abnormality becomes visible early, when correction is simple and risk is low. This is a core Quality function, not a maintenance preference.

In poorly controlled environments, equipment condition is masked by accumulated materials, temporary fixtures, and informal storage. Oil leaks blend into grime. Wear goes unnoticed. Loose components remain hidden. Operators learn to work around these conditions, and breakdowns are treated as unavoidable events. In mixed-model human–humanoid production, this lack of visibility introduces immediate risk. Humanoid robots rely on stable interfaces, clear access zones, and predictable equipment condition. When abnormalities are hidden, safe operation cannot be assured.

Figure 17: Restoring Equipment Conditions to Reveal Abnormalities

Clean, organized equipment surfaces expose deterioration, enable early detection, and protect Quality at the source.

Using 5S to Support Built-In Quality

Restoring equipment condition begins with removing what does not belong. Excess tools, temporary mounts, unused fixtures, and accumulated materials prevent clear observation and interfere with access. Once removed, Shine restores surfaces so leaks, cracks, looseness, and wear are immediately apparent. This transforms cleaning into inspection and shifts detection upstream.

From a Quality perspective, visible equipment condition prevents defects caused by unstable machines and degraded tooling. From a safety perspective, clear access and defined zones reduce exposure to hazards during operation and inspection. For humanoid robots, restored equipment condition ensures that physical interfaces, sensor reference points, and motion envelopes remain consistent with system assumptions.

This discipline also supports Jidoka. When equipment condition is visible, abnormalities can be detected and addressed before defects propagate. Operators and leaders can see problems directly rather than relying on alarms or failures. This strengthens problem solving and reinforces accountability at the source.

Restoring equipment conditions through 5S Thinking is not periodic cleanup. It is a daily discipline that protects Quality by ensuring machines operate within known, observable limits. By revealing abnormality early, Lean TPS prevents failure, supports stable operation, and creates the conditions required for safe, reliable collaboration between humans and humanoid robots.

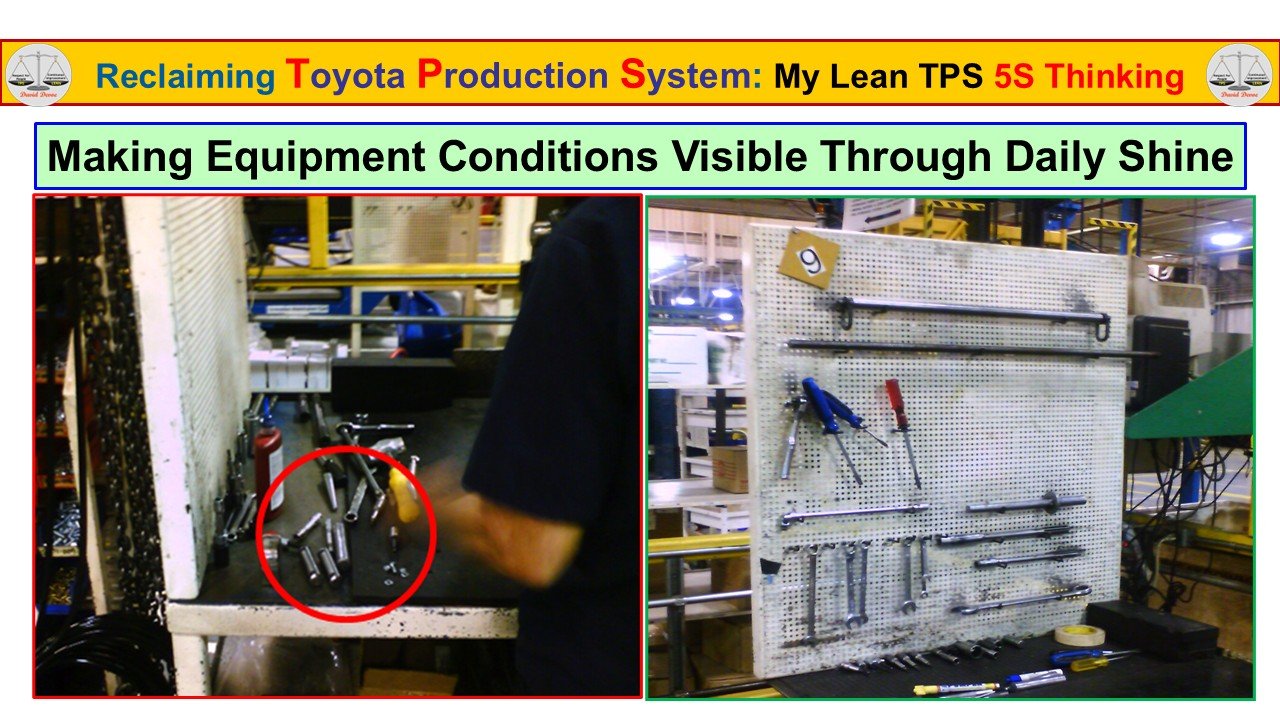

18. Making Equipment Conditions Visible Through Daily Shine

Using Daily Inspection to Prevent Hidden Deterioration

Equipment condition degrades gradually, not suddenly. Dirt accumulates, fasteners loosen, wear progresses, and minor leaks begin without immediate impact. When these changes are hidden by clutter or neglected cleaning, problems advance until failure occurs. Lean TPS 5S Thinking uses daily Shine to prevent this by making equipment condition visible and abnormalities unmistakable. Cleaning is not performed for appearance. It is performed to reveal reality.

In workplaces without daily Shine, tools are left where they were last used, surfaces are not restored, and abnormal conditions blend into the background. Operators adapt by working around issues rather than correcting them. This adaptation hides deterioration and increases the likelihood of defects, breakdowns, and safety incidents. In mixed-model human–humanoid production, this risk is amplified. Humanoid robots rely on clean reference surfaces, clear interfaces, and predictable equipment condition. Contamination and disorder interfere with perception and motion, increasing the probability of error.

Figure 18: Making Equipment Conditions Visible Through Daily Shine

Daily cleaning restores visual clarity, exposes abnormal conditions, and protects Quality before defects occur.

Daily Shine as a Quality Control Mechanism

Daily Shine establishes a routine where equipment is returned to a known condition at the end of each shift or cycle. Tools are returned to their defined locations. Surfaces are wiped so leaks, wear, and damage stand out immediately. This routine creates a clear baseline against which change can be detected quickly.

From a Quality perspective, daily Shine prevents defects caused by unstable equipment and unnoticed deterioration. It supports Jidoka by enabling early detection and response at the source. From a safety perspective, it reduces hazards associated with slippery surfaces, obstructed access, and unexpected equipment behavior.

For humanoid robots, daily Shine ensures that sensors receive accurate visual input and that physical interfaces remain consistent with programmed assumptions. Clean, ordered environments reduce noise in perception systems and support reliable execution.

Daily Shine also reinforces discipline. It builds habit, not dependency on audits or periodic events. When performed consistently, it prevents drift and sustains environmental control over time.

Making equipment conditions visible through daily Shine is essential for maintaining readiness. It protects Quality by exposing problems early, supports safe operation, and ensures that both humans and humanoid robots can perform work in a stable, predictable environment.

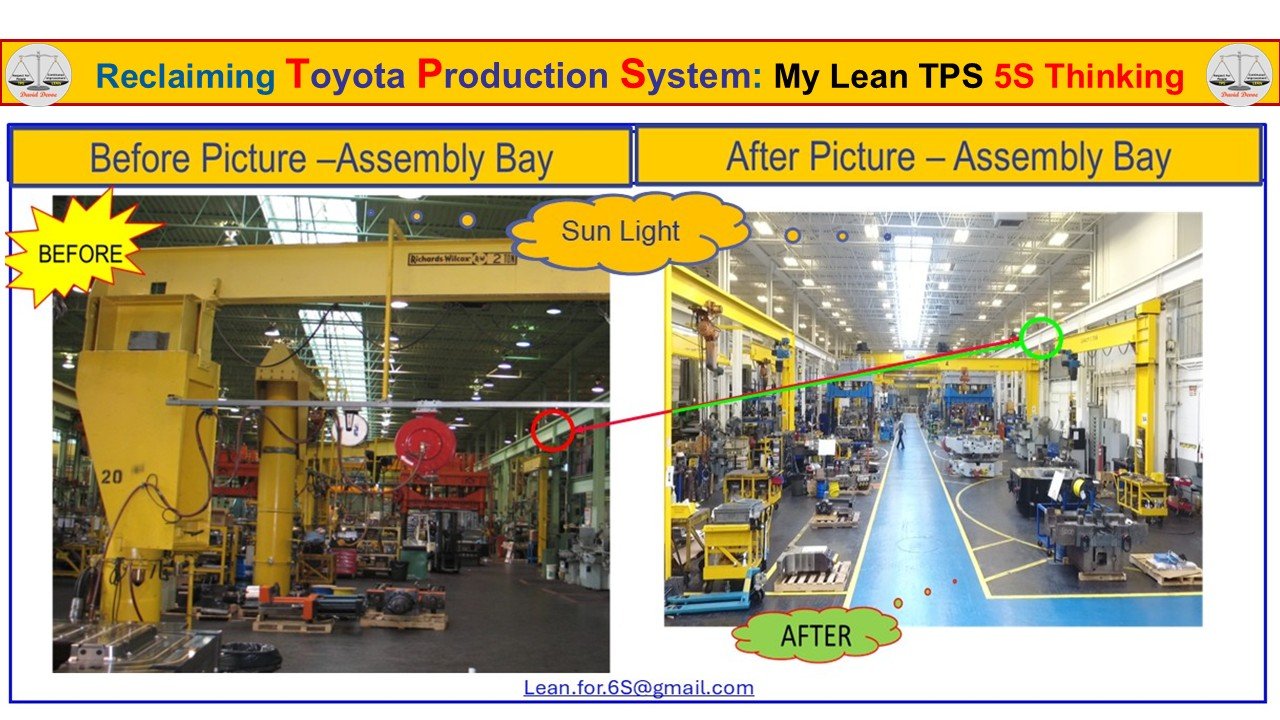

19. Restoring Flow and Visibility Through Set in Order

Making Space, Direction, and Abnormality Immediately Obvious

Set in Order restores the workplace so that space, direction, and purpose are visually obvious. The before condition in assembly environments typically reflects uncontrolled growth. Equipment accumulates, temporary placements become permanent, aisles narrow, and visual depth is lost. As a result, leaders and operators lose the ability to see flow, detect congestion, or recognize abnormal conditions in real time.

In Lean TPS, Set in Order is not about neatness. It is about restoring the physical logic of the production system. When equipment, materials, and travel paths are deliberately positioned, the workplace itself communicates how work should move. Clear aisles, consistent orientation, and defined boundaries allow anyone entering the area to immediately understand direction, priority, and status.

Figure 19: Restoring Flow and Visibility Through Set in Order

Deliberate layout, clear travel paths, and visual depth restore flow and make abnormal conditions visible at a distance.

Visibility as a Requirement for Flow and Quality

The after condition demonstrates how Set in Order restores visual depth and line of sight across the assembly bay. Natural and artificial lighting now reach deeper into the workspace. Equipment no longer blocks aisles or sightlines. Floor markings define travel paths and working zones, preventing drift and encroachment over time.

This visibility is essential for Quality. When flow paths are clear, congestion becomes immediately obvious. When equipment is positioned consistently, misplacement and obstruction stand out. Leaders can observe from a distance without interrupting work, enabling faster response to emerging problems.

In mixed-model human–humanoid production, these conditions are mandatory. Humanoid robots require predictable travel corridors, consistent spatial references, and unobstructed visual fields. Set in Order provides the geometric stability that allows robots to move safely while enabling humans to maintain situational awareness across the system.

Set in Order also reinforces discipline. Once space and direction are clearly defined, deviation becomes visible and correctable. This prevents gradual erosion of flow and protects the system from reverting to uncontrolled conditions.

Restoring flow and visibility through Set in Order enables stable operation, protects Quality, and ensures that both humans and humanoid robots can work within a system that is readable, predictable, and resilient.

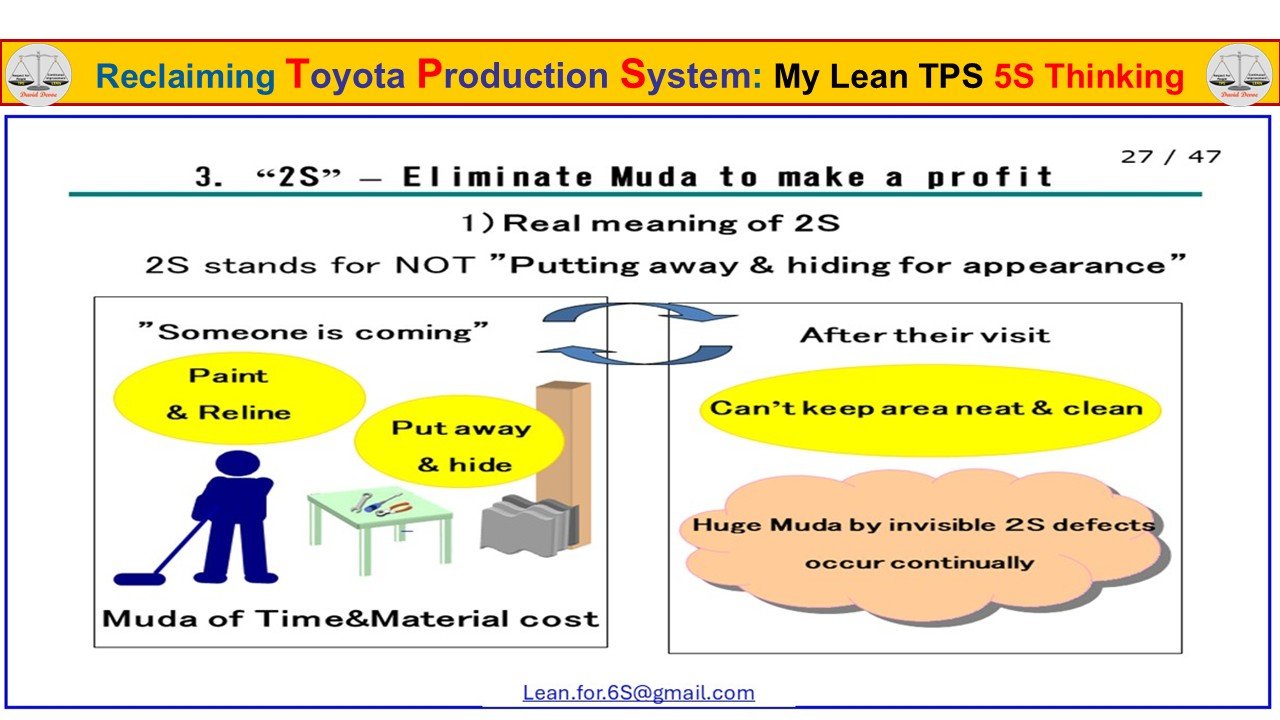

20. The Real Meaning of 2S: Eliminating Hidden Muda, Not Creating Appearance

Why Set in Order Is Not “Put Away and Hide”

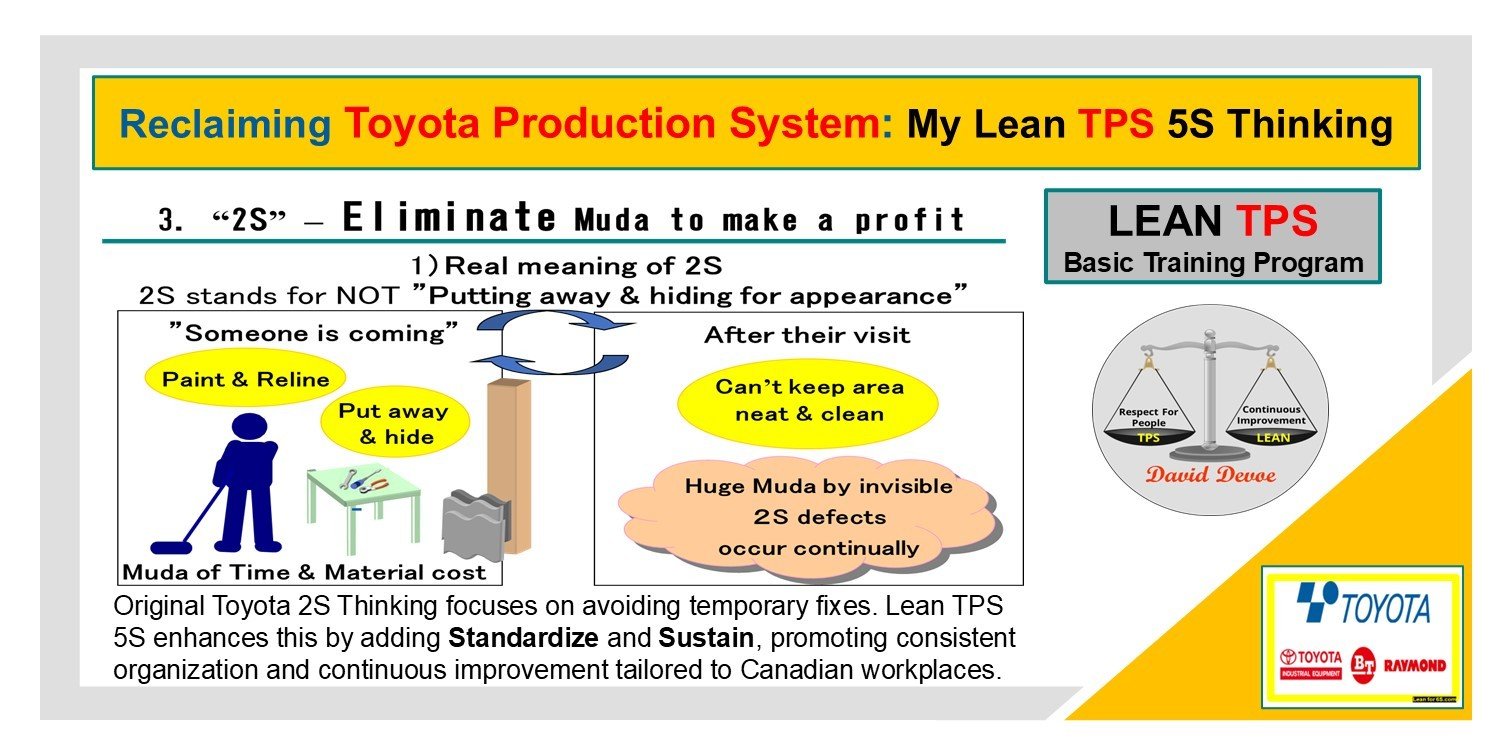

The image makes a critical distinction that is often lost in 5S deployments. The real meaning of the first two S steps is not cleaning up for visitors or restoring appearance temporarily. In Lean TPS, 2S is not “put away and hide.” When teams react to an upcoming visit by painting, relining, and hiding items, they are not practicing Set in Order. They are creating a short-lived illusion that masks the true condition of the workplace.

This behavior introduces direct waste. Time and materials are consumed repainting and rearranging without changing the underlying system. Tools are hidden instead of given defined homes. Materials are moved instead of addressed. The result is Muda that provides no lasting improvement to Quality, safety, or productivity.

Figure 20: The Real Meaning of 2S

Temporary cleanup for appearance hides problems and creates recurring waste, while true Set in Order exposes issues and eliminates Muda at the source.

Visibility Versus Concealment

The right side of the image shows the inevitable outcome of appearance-based 2S. Once the visit is over, the workplace quickly returns to disorder. The organization cannot sustain cleanliness because nothing structural has changed. Locations are undefined, quantities are unclear, and responsibilities are ambiguous. As a result, invisible defects accumulate continuously. This hidden Muda is far more damaging than visible disorder because it prevents early detection and correction.

Lean TPS treats visibility as non-negotiable. Set in Order exists to make problems obvious, not to make spaces look good. When items have fixed locations, when quantities are defined, and when layouts support the work, abnormality stands out immediately. This allows teams to correct causes instead of repeatedly treating symptoms.

In mixed-model human–humanoid production, concealment is especially dangerous. Robots depend on stable locations, predictable geometry, and consistent visual references. Hiding items or temporarily rearranging the environment introduces instability that compromises safety and Quality. Humans also lose trust in the system when order cannot be sustained without constant cleanup events.

True 2S eliminates Muda by designing order that holds every day. It replaces appearance-driven behavior with system discipline. When Set in Order is practiced correctly, the workplace remains stable before, during, and after any visit, and Quality becomes a property of the system rather than an act of preparation.

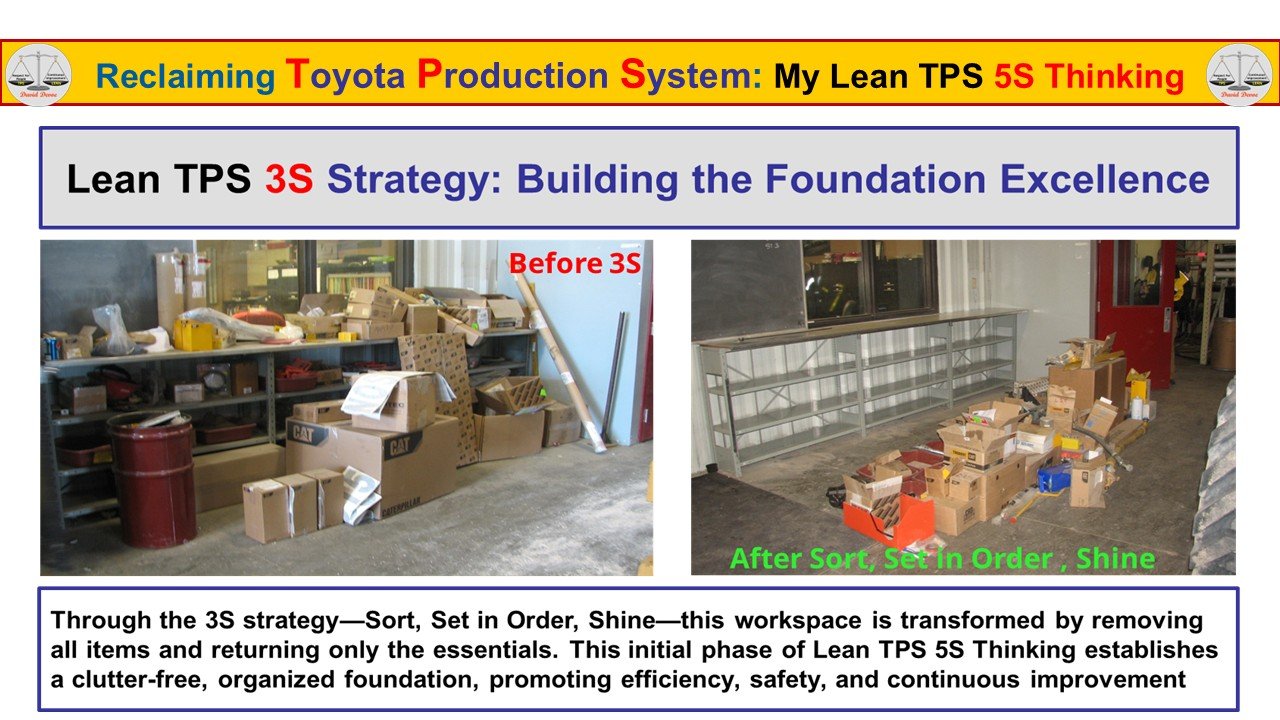

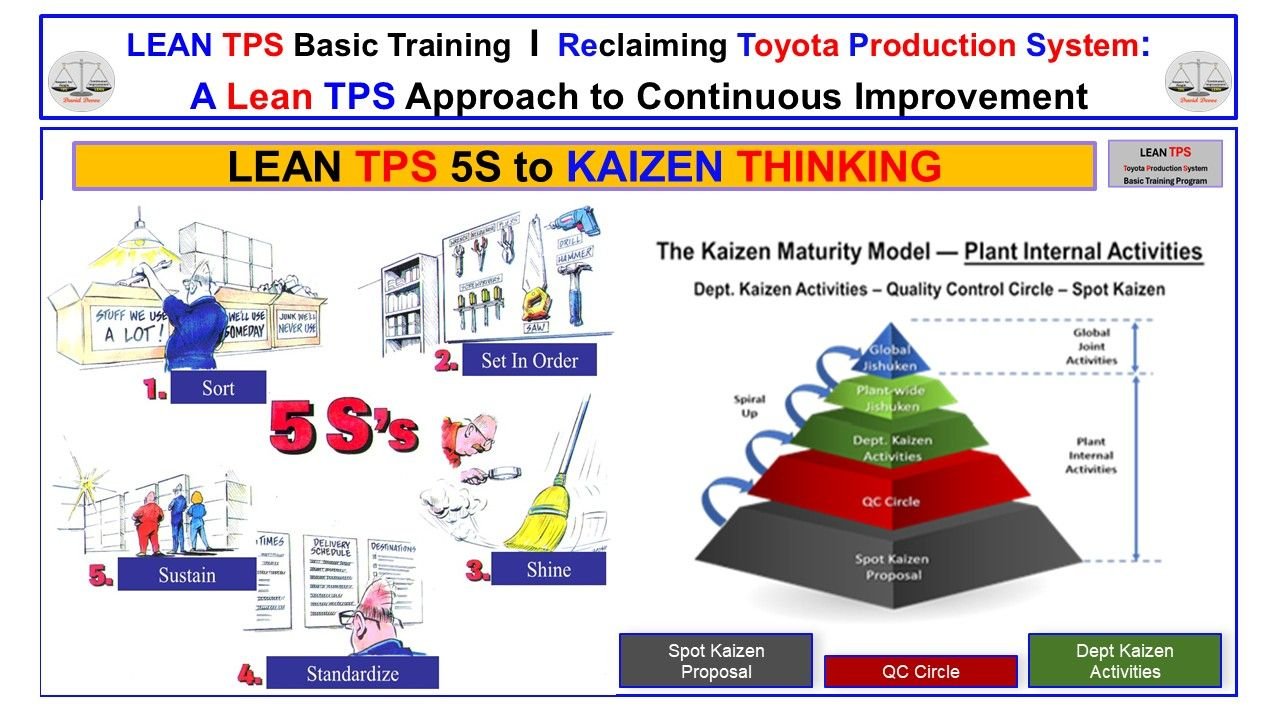

21. Lean TPS 3S Strategy: Building the Foundation for Excellence

Why 3S Comes Before Everything Else

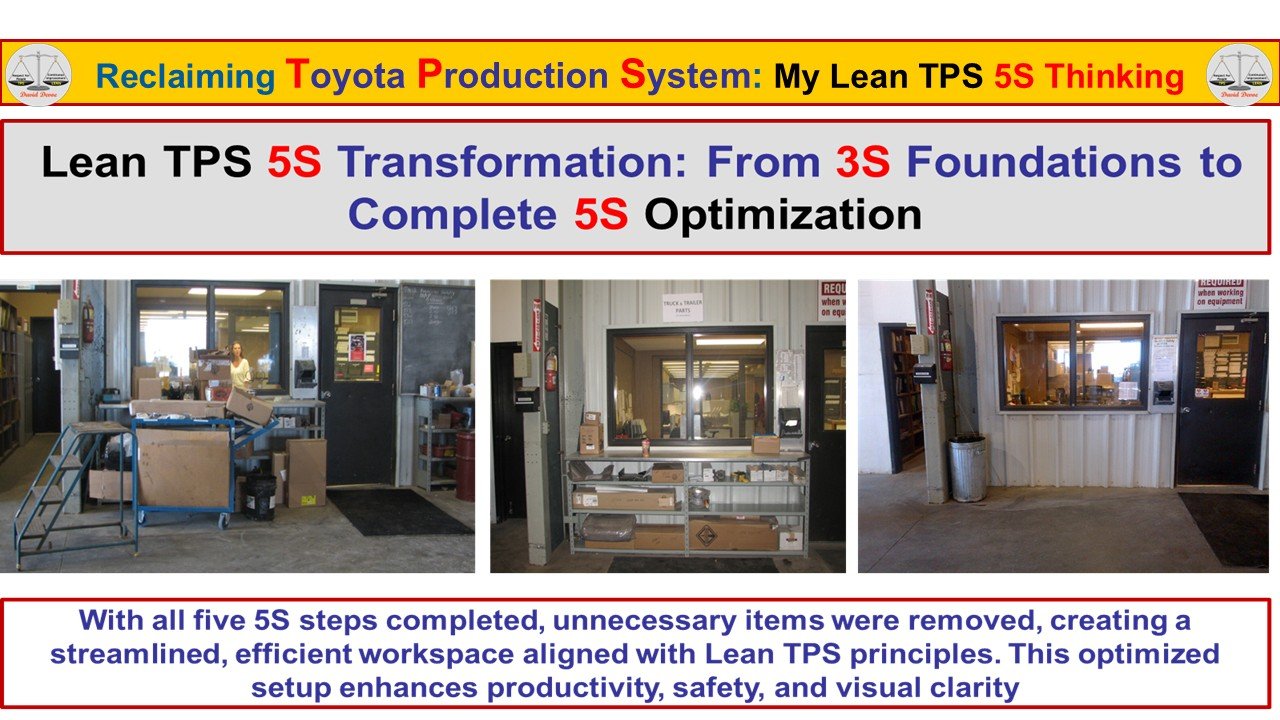

This image captures the role of 3S as the foundation of Lean TPS, not as a cleanup exercise but as a deliberate system reset. Sort, Set in Order, and Shine are applied together to remove accumulated clutter, restore basic conditions, and expose the true state of the workplace. Until this foundation is established, higher-level improvement activity is built on instability.

Before 3S, the workspace is overloaded with mixed materials, unknown inventory, and unclear ownership. Items accumulate because no decision has been made about what is truly required for daily work. This condition hides problems, slows response, and erodes Quality. People compensate by searching, stepping around obstacles, and improvising, which normalizes waste and risk.

3S interrupts that cycle by forcing decisions.

Figure 21: Lean TPS 3S Strategy

Sort, Set in Order, and Shine remove all nonessential items and reintroduce only what is required, creating a stable and visible foundation for Quality and continuous improvement.

Restoring Stability Before Improvement

The after condition shown in the image is not yet a finished system. That is intentional. What matters at this stage is that the space is empty enough to think, see, and design. By removing everything and returning only essential items, teams regain control over the environment. Locations can now be defined logically. Quantities can be set intentionally. Cleaning becomes inspection rather than janitorial work.

Lean TPS treats 3S as a prerequisite for Standardized Work, flow, and visual management. Without this reset, standards are written to accommodate disorder instead of eliminating it. With 3S in place, abnormalities stand out immediately, and maintaining order requires far less effort.

In mixed-model human–humanoid environments, this foundation is even more critical. Robots require predictable space, clear boundaries, and stable layouts. Humans require clarity, safety, and confidence that the system supports their work. 3S provides both by removing ambiguity and restoring baseline conditions.

3S is not about making the workplace look better. It is about making the workplace governable. Once this foundation exists, improvement becomes systematic, Quality becomes repeatable, and continuous improvement can progress without constantly fighting the same underlying chaos.

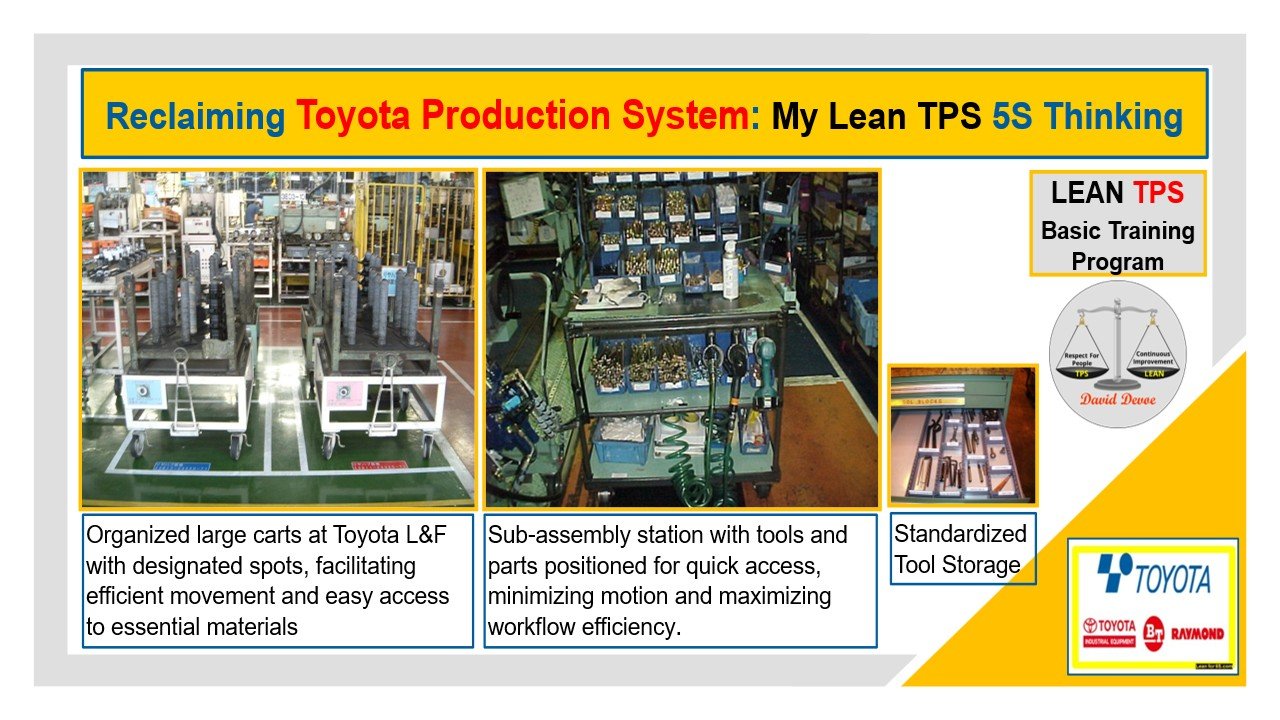

22. Set in Order as System Design, Not Visual Decoration

How Physical Arrangement Protects Quality and Reduces Motion Waste

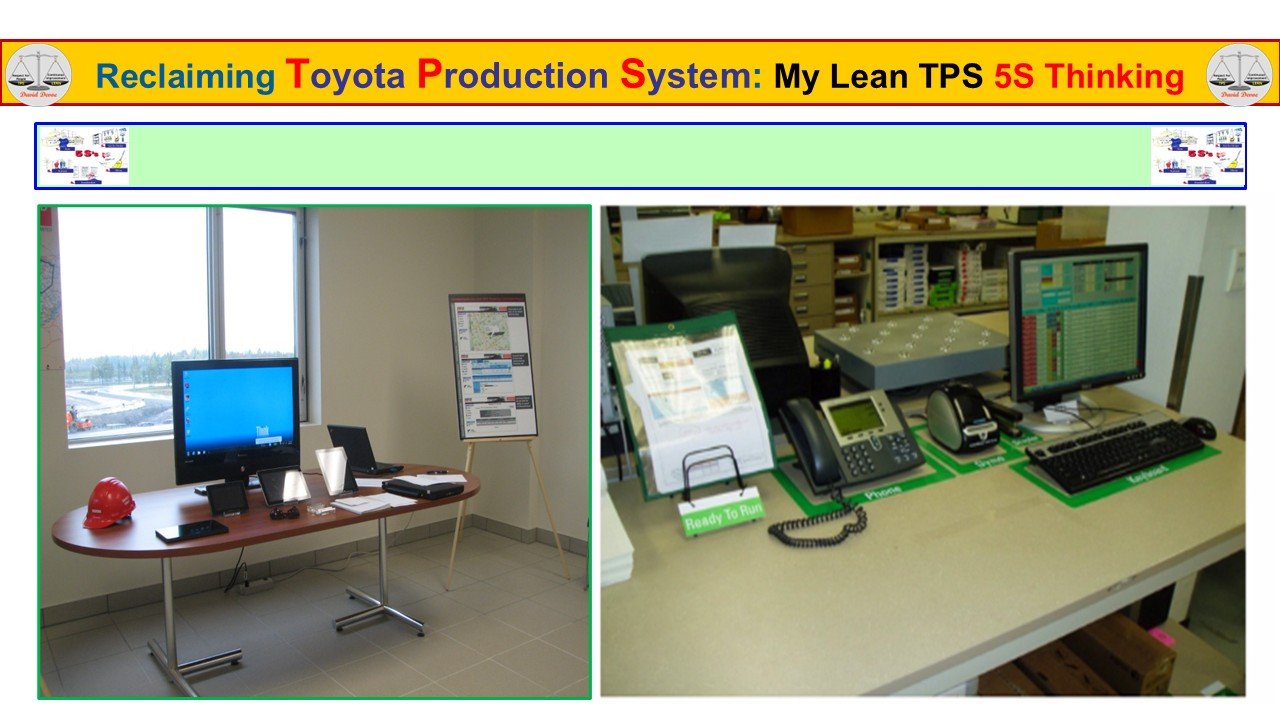

Set in Order is often misunderstood as a labeling or shadow board activity. In Lean TPS, Set in Order is the deliberate design of the physical system so that work can be performed correctly, repeatedly, and safely without reliance on memory or personal habit. The objective is not visual appeal. The objective is protection of Quality through stable locations, defined quantities, and predictable access.

The images in this section show Set in Order applied as system design. Carts, tools, and sub-assembly materials are positioned based on how the work is performed, not where space happens to be available. This distinction matters. When locations are designed around the work sequence, motion is reduced, errors are prevented, and abnormal conditions become immediately visible.

Set in Order establishes the physical rules of the workplace. When those rules are clear, both people and systems can operate without constant adjustment, searching, or workaround behavior.

Figure 22: Set in Order as System Design

Carts, tools, and sub-assembly materials are positioned in defined locations to support flow, minimize motion, and make abnormal conditions visible at a glance.

Designing Order That Holds Under Daily Use

The examples shown are not staged improvements. They represent working conditions that can be sustained every shift. Large carts are given designated home positions with clear orientation and boundaries. Sub-assembly stations position parts and tools within reach, eliminating unnecessary motion and reducing the risk of selection errors. Standardized tool storage ensures that missing or misplaced tools are immediately obvious.

This is where Set in Order directly supports Quality. When tools return to the same location every time, wear, damage, and loss are detected early. When parts are staged in defined quantities, shortages and overproduction are exposed before they affect downstream processes. When carts have fixed positions, flow paths remain clear and safety risks are reduced.

Lean TPS treats Set in Order as a control mechanism, not a cleanup activity. It replaces reliance on individual discipline with system discipline. People no longer need to remember where things belong. The system tells them.

In mixed-model human–humanoid production, this principle becomes non-negotiable. Robots require fixed geometry, repeatable access points, and stable reference locations. Humans require clarity, reach efficiency, and confidence that the environment will not change unexpectedly. Set in Order satisfies both by locking physical relationships into the system.

When Set in Order is designed correctly, the workplace maintains itself. Order does not collapse under pressure, and Quality is protected without additional effort. This is the role of Set in Order within Lean TPS. It is not decoration. It is system architecture.

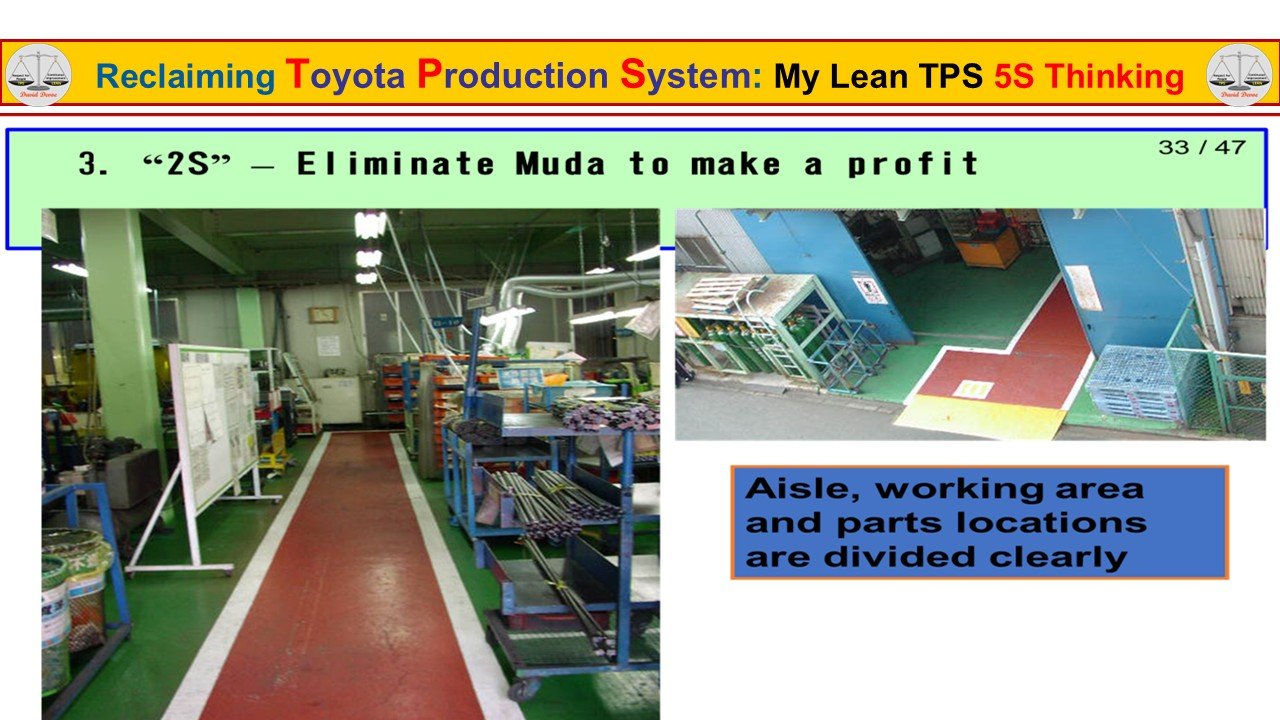

23. Set in Order Eliminates Muda by Physically Separating Functions

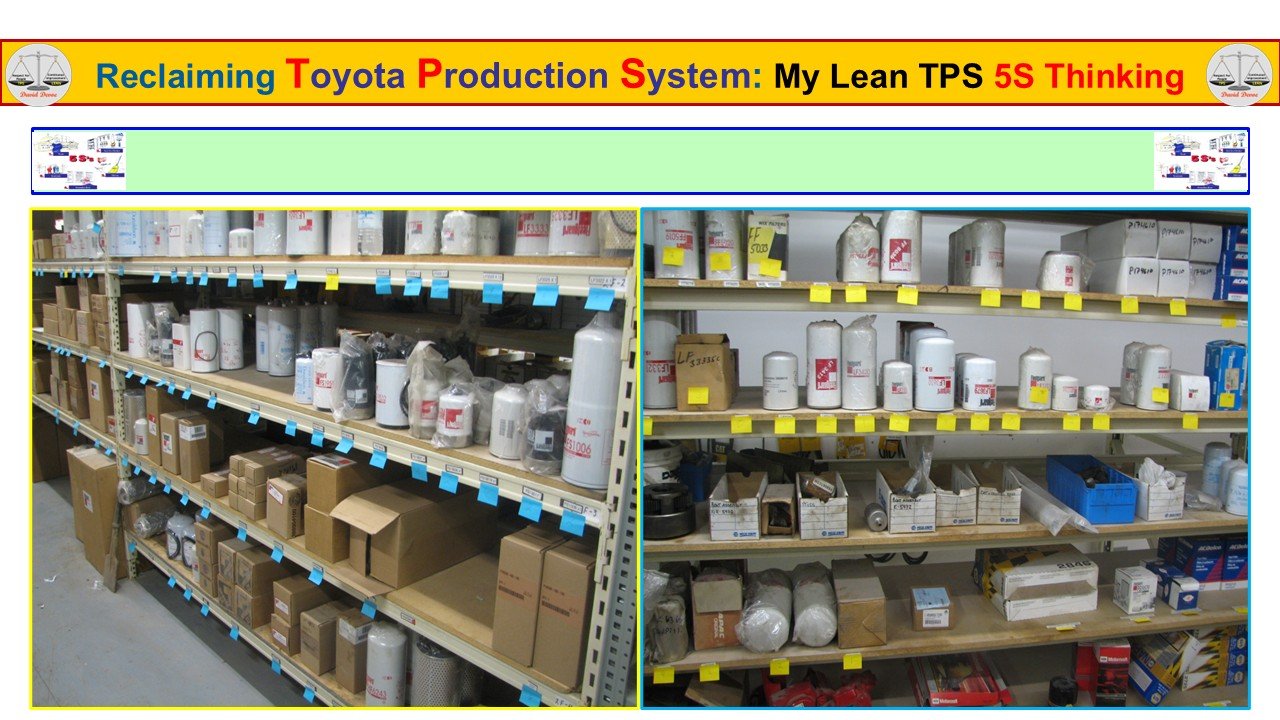

Clear Division of Aisles, Work Areas, and Parts Locations

Set in Order reaches maturity when physical space itself enforces correct behavior. In Lean TPS, this means aisles, working areas, and parts locations are not only identified but unmistakably separated. Without this separation, even a clean and organized workplace will slowly degrade as functions overlap and boundaries erode. The image below shows how clear physical division removes ambiguity and prevents Muda from re-entering the system.

Figure 23: Physical Separation of Aisles, Work Areas, and Parts Locations

Clear visual boundaries prevent interference, protect flow, and eliminate waste caused by mixed-use spaces.

One of the most common sources of recurring Muda is mixed-use space. When aisles double as storage, when parts creep into work areas, or when work expands into walking paths, waste becomes embedded in daily operations. Extra motion is required to navigate obstacles. Safety risks increase. Material flow becomes unpredictable. Over time, these conditions are normalized, and the organization loses the ability to distinguish normal from abnormal.

Lean TPS uses Set in Order to prevent this erosion by assigning each area a single, unmistakable purpose. Aisles exist only for movement. Work areas exist only for value creation. Parts locations exist only for defined quantities of material. Floor markings, color coding, and physical boundaries make these roles visible at a glance. When an item appears in the wrong zone, the problem is immediately obvious without discussion or inspection.

This separation directly protects Quality. When parts remain confined to designated locations, the risk of mixing, damage, or incorrect usage is reduced. When work areas remain clear of intrusion, operators can perform Standardized Work without compensation or workaround. When aisles remain unobstructed, material delivery and removal occur predictably, supporting flow and takt adherence.

Clear separation also stabilizes behavior. Operators do not need to make judgment calls about where to place items or how to navigate space. The system makes the correct action obvious. This reduces cognitive load, shortens reaction time, and increases consistency across shifts. Over time, discipline is sustained not through enforcement but through design.

In environments involving mixed-model human–humanoid production, this discipline becomes critical. Humanoid robots rely on fixed paths, stable work zones, and predictable material presentation. Any encroachment into aisles or work areas introduces instability that cannot be safely absorbed. Clear physical separation protects both humans and machines by eliminating uncontrolled interaction at the source.

Set in Order, when executed correctly, eliminates Muda by design rather than by effort. By clearly dividing aisles, working areas, and parts locations, Lean TPS prevents disorder from reappearing, protects flow, and ensures that Quality is maintained through structure rather than constant intervention.

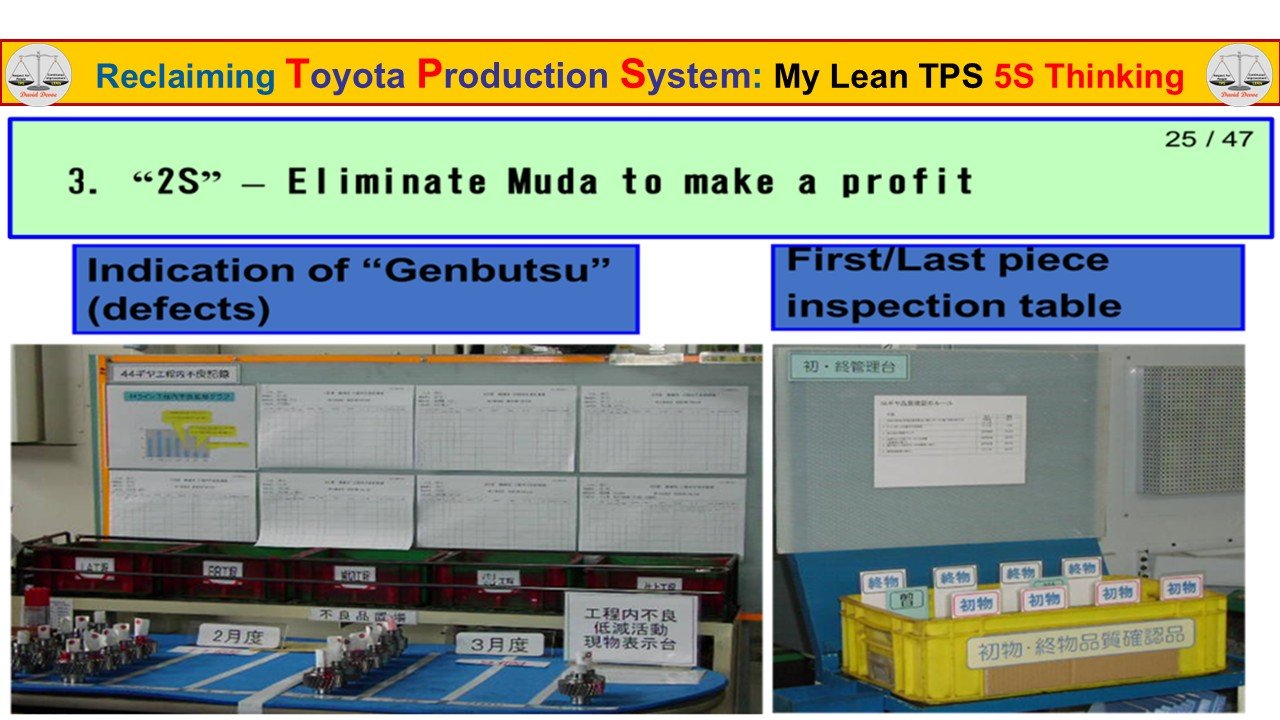

24. Set in Order Makes Defects Visible at the Point of Use

Using Physical Location to Expose Genbutsu and Quality Abnormalities

Set in Order is not limited to organizing tools and materials. In Lean TPS, it is also used to make Quality conditions visible in real time. By assigning fixed locations for inspection, defects, and first and last pieces, the system prevents problems from being hidden, delayed, or normalized. The image below shows how physical arrangement exposes genbutsu and supports built-in Quality.

Figure 24: Set in Order for Genbutsu Visibility and First/Last Piece Inspection

Dedicated locations for defects and inspection prevent concealment and force immediate recognition of Quality abnormalities.

Quality problems persist when defects are allowed to disappear into the flow of work. When nonconforming parts are placed temporarily on benches, mixed with good parts, or moved without a defined process, the organization loses the ability to see the true condition of production. Lean TPS uses Set in Order to prevent this by giving defects and inspection activities a fixed, unmistakable place in the workplace.

The image illustrates two critical applications. On the left, defects are indicated and collected in a clearly defined area associated with genbutsu. Abnormal parts are not hidden, reworked quietly, or delayed for later discussion. Their presence is visible to operators, leaders, and support functions. This visibility creates immediate pressure to understand cause rather than simply manage symptoms.

On the right, the first and last piece inspection table establishes a clear Quality checkpoint within the flow of work. By assigning a fixed location for initial and final verification, the system ensures that inspection is not skipped, rushed, or performed inconsistently. The physical presence of the inspection area reinforces the expectation that Quality is confirmed deliberately, not assumed.

Set in Order plays a critical role here by removing discretion. Operators are not left to decide where to place defective items or when to inspect. The system dictates the correct action through layout and location. When a defect appears outside its designated area, or when inspection materials are missing, the abnormality is immediately obvious.

This design supports Jidoka by making problems visible at the moment they occur. Defects do not travel downstream unnoticed. Leaders do not need reports or metrics to know there is a Quality issue. The condition of the workplace itself communicates the status of production.

In mixed-model human–humanoid environments, this visibility becomes even more important. Robots cannot compensate for ambiguous Quality signals. Fixed locations for inspection and defects provide predictable reference points that support safe interaction and consistent decision-making. Humans benefit equally by gaining confidence that the system will not allow problems to be ignored or buried.

Set in Order, when applied to Quality, transforms inspection from an activity into a condition. By using physical location to expose genbutsu and control first and last piece verification, Lean TPS ensures that defects are addressed immediately, Quality is protected at the source, and Muda associated with delayed detection is eliminated.

25. Fixed Locations and FIFO Prevent Hidden Inventory and Scheduling Muda

Set in Order as a Control Mechanism for Intermediate Flow

Set in Order is the mechanism Lean TPS uses to control intermediate inventory and prevent silent buildup of Muda. By deciding fixed locations, defining capacity, and enforcing FIFO discipline, the system makes flow interruptions, overproduction, and delay immediately visible instead of allowing them to accumulate unnoticed.

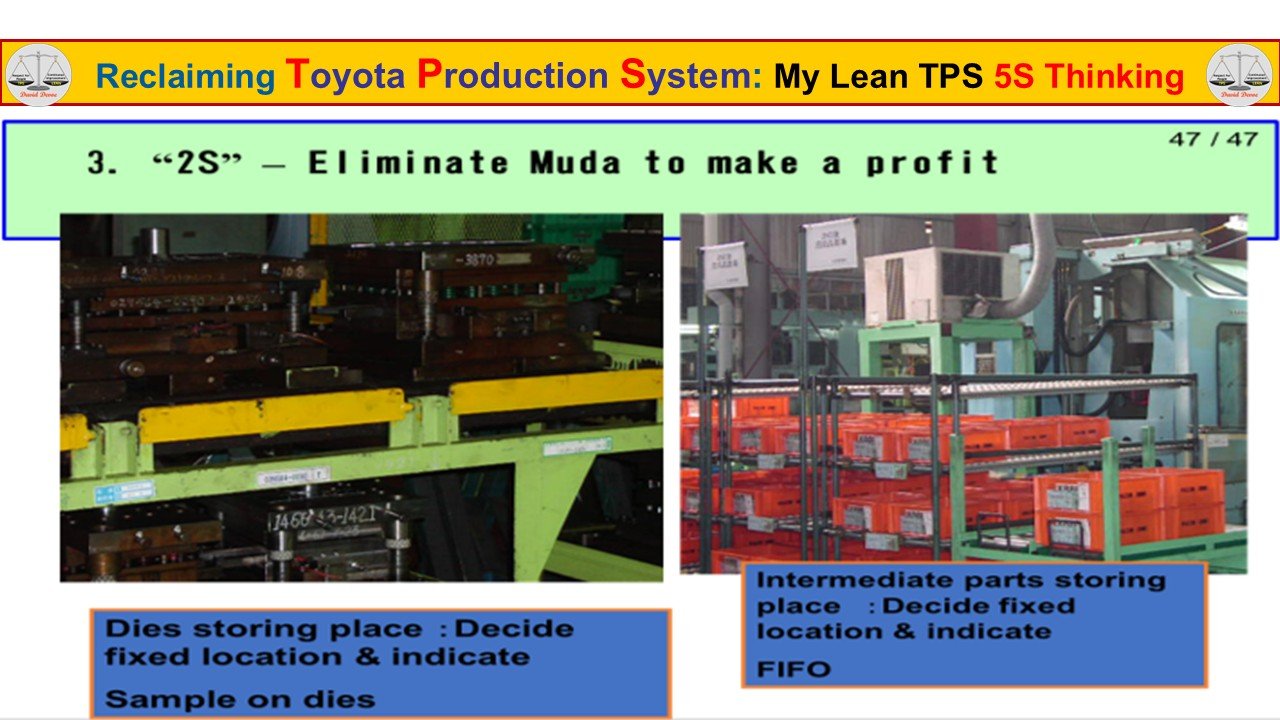

Figure 25: Fixed Locations and FIFO for Dies and Intermediate Parts

Decided locations and FIFO lanes control inventory flow, prevent concealment, and expose abnormalities in production rhythm.

Intermediate inventory is one of the most common sources of hidden waste in production systems. When parts, dies, or subcomponents are allowed to sit wherever space is available, problems disappear from view. Excess inventory masks imbalance, delays feedback, and creates the illusion of stability while performance erodes underneath.

The image illustrates how Lean TPS uses Set in Order to prevent this condition. On the left, dies are stored in a fixed, clearly indicated location. Their position is not arbitrary and not flexible. The location itself becomes part of the control system. When a die is missing, misplaced, or stacked incorrectly, the abnormality is visible without discussion. Leaders do not need to ask where the die is. The workplace answers the question immediately.

On the right, intermediate parts are stored in a defined FIFO lane. Location and sequence are decided in advance. Parts enter from one side and exit from the other. This design prevents cherry-picking, batching, and schedule-driven shortcuts that destroy flow. When FIFO is broken, the violation is obvious. When inventory exceeds its defined capacity, the overflow signals a problem upstream or downstream that requires correction.

Set in Order functions here as a governor on behavior. Operators are not relied upon to remember FIFO rules or inventory limits. The physical layout enforces them. This removes variation caused by individual judgment and replaces it with system discipline. As a result, flow problems are surfaced early instead of being absorbed by excess inventory.

This approach directly supports Just-in-Time. By fixing locations and limiting space, the system restricts how much inventory can exist between processes. Overproduction cannot hide because there is nowhere for it to go. Delays cannot be ignored because FIFO lanes stop moving. Each abnormal condition demands a response.

Quality is also protected. When parts wait too long, are mixed out of sequence, or are handled repeatedly, defect risk increases. FIFO reduces aging, handling damage, and confusion about production status. Fixed locations ensure that abnormal parts or delays stand out instead of blending into the background.

In mixed-model human–humanoid environments, this discipline is essential. Robots depend on predictable locations and sequence to operate safely and accurately. Humans depend on clarity to manage exceptions without improvisation. Fixed locations and FIFO provide both by stabilizing flow and eliminating ambiguity.

Set in Order, when applied to intermediate inventory, is not about storage efficiency. It is about flow integrity. By deciding locations, enforcing FIFO, and limiting capacity, Lean TPS eliminates hidden Muda, restores visibility, and ensures that production problems are addressed at the source rather than buffered away by excess inventory.

26. From Isolated 2S Examples to System Stability

Why 2S Must Transition From Technique to System Control

Up to this point, the focus has been on the practical execution of 2S. Fixed locations, visual separation, FIFO discipline, and clear identification of abnormalities remove waste and stabilize daily work at the point of use. These controls eliminate conditions that allow instability to persist unnoticed.

2S is often misunderstood as tidying or visual enhancement. In Lean TPS, 2S removes hidden instability from the system. When locations are not fixed, ownership is unclear, and abnormal conditions blend into daily work, waste becomes normalized. Motion increases, response is delayed, inventory grows, and management shifts from prevention to reaction. Quality deteriorates before work begins.

Figure 26: Transition from Isolated 2S Practices to System-Level Stability

Individual 2S controls evolve into integrated system stability, shifting Lean TPS 5S Thinking from localized organization to sustained control of Quality, flow, and daily work conditions.

From Visible Order to Sustained Stability

When order is established correctly, problems surface immediately. Flow becomes visible. Decisions move closer to the work. Operators no longer compensate for poor layout, missing standards, or unclear expectations. Stability is enforced by the workplace itself rather than by individual effort.

As pressure increases, isolated controls are insufficient. Without reinforcement, even well-executed 2S conditions decay. Tools drift, locations blur, and abnormalities lose their signal. Stability erodes quietly.

Sustained stability requires physical definition, visual control, and daily confirmation. Correct conditions must be obvious and incorrect conditions unacceptable. Only then can Quality, safety, and flow be protected consistently.

27. Standardize: Making Order Repeatable

Why Standards Are the Only Way 5S Holds

Standardize converts improvement into normal work. Without standardization, even well-executed 5S conditions depend on memory, habit, and personal judgment. That dependence introduces variation before work begins and allows instability to re-enter the system quietly over time.

In an unstandardized environment, equipment placement, orientation, and setup differ by operator or shift. Even when the area appears orderly, the condition cannot be reproduced consistently. Each reset requires thinking, adjustment, and negotiation. This variability erodes Quality because work no longer starts from a known, controlled condition.

Figure 27: Standardized Equipment Home Locations

Defined footprints and fixed locations make deviation visible immediately and ensure repeatable setup across shifts and operators.

Standardized locations remove that variability by physically defining the expected condition. Each item has a fixed home position, orientation, and footprint. The workplace itself communicates what is correct. When an item is missing, misplaced, or incorrectly oriented, the abnormality is immediately visible without explanation or inspection.

In Lean TPS, Standardize is not documentation. It is physical definition. Standards exist first in the workplace, not in binders. Visible, physical standards eliminate reliance on memory and experience to maintain order. Deviation becomes obvious, and correction becomes immediate.