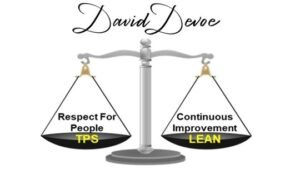

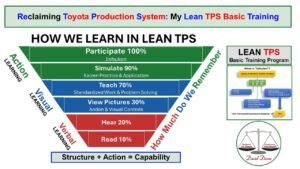

Lean TPS support is available for plant teams, regional operations, and leadership development. Support focuses on structured improvement, capability building, and systems-based problem solving grounded in Toyota Production System methods.

Services include:

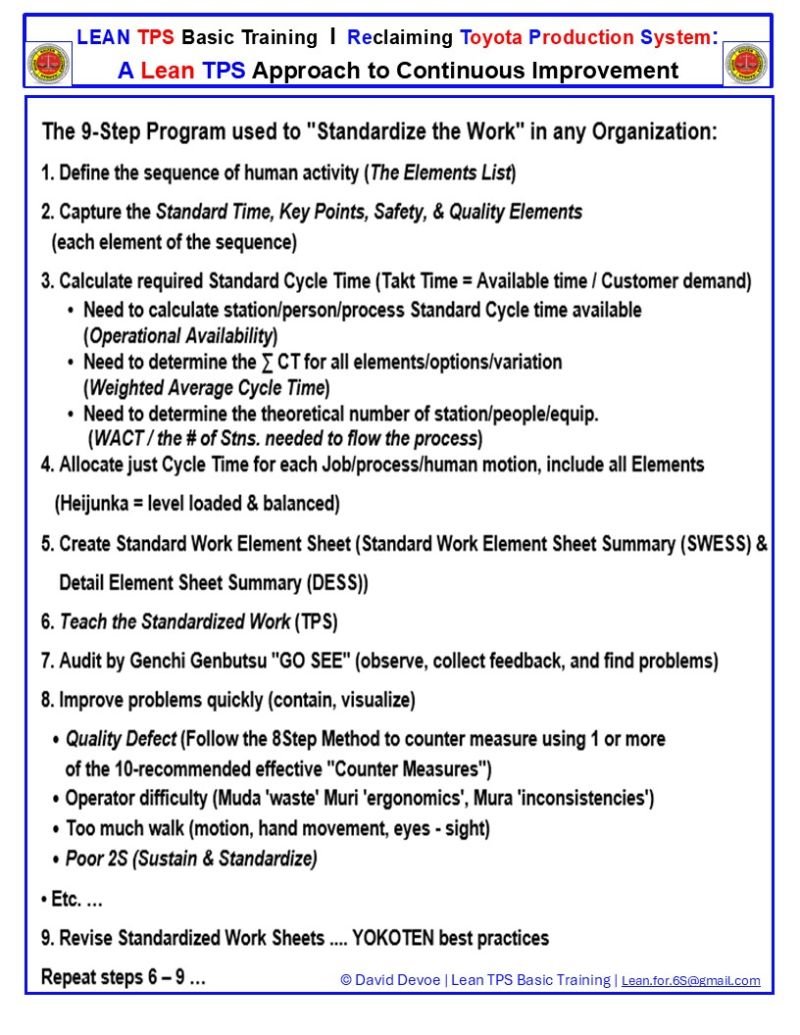

Continuous Improvement Facilitation

Structured guidance to stabilize flow, expose abnormalities, and strengthen daily management through Standardized Work.

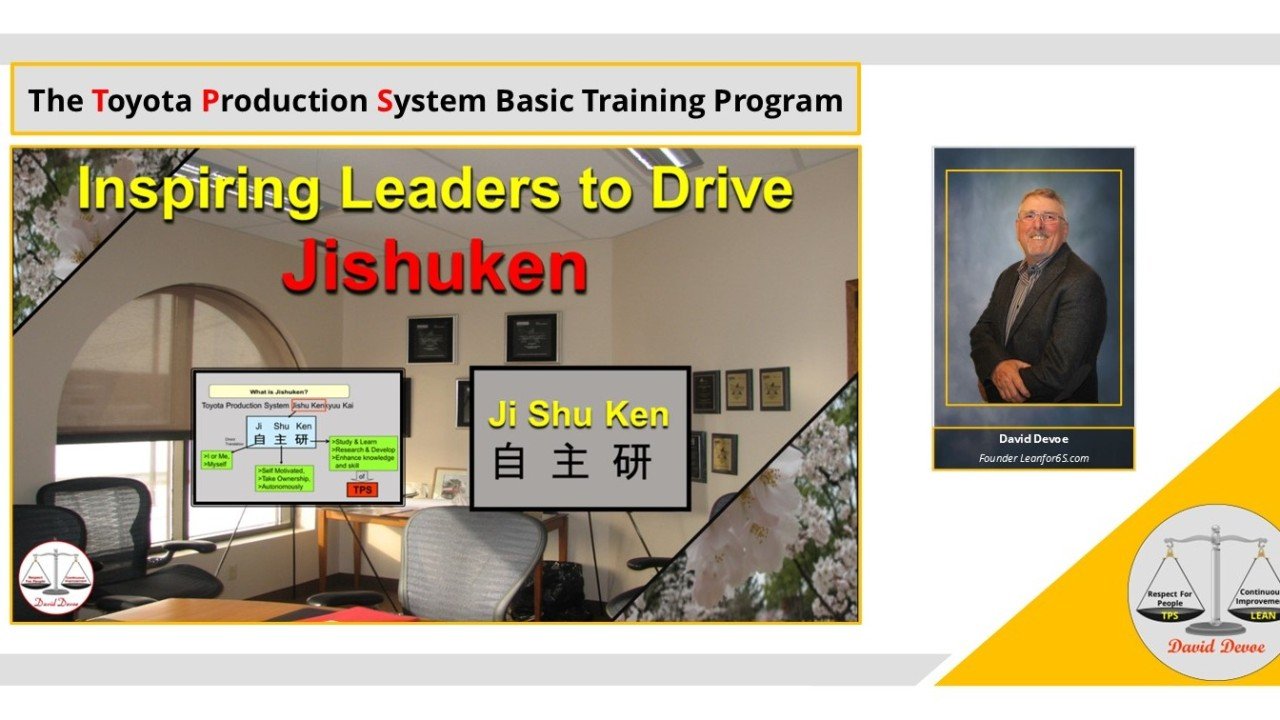

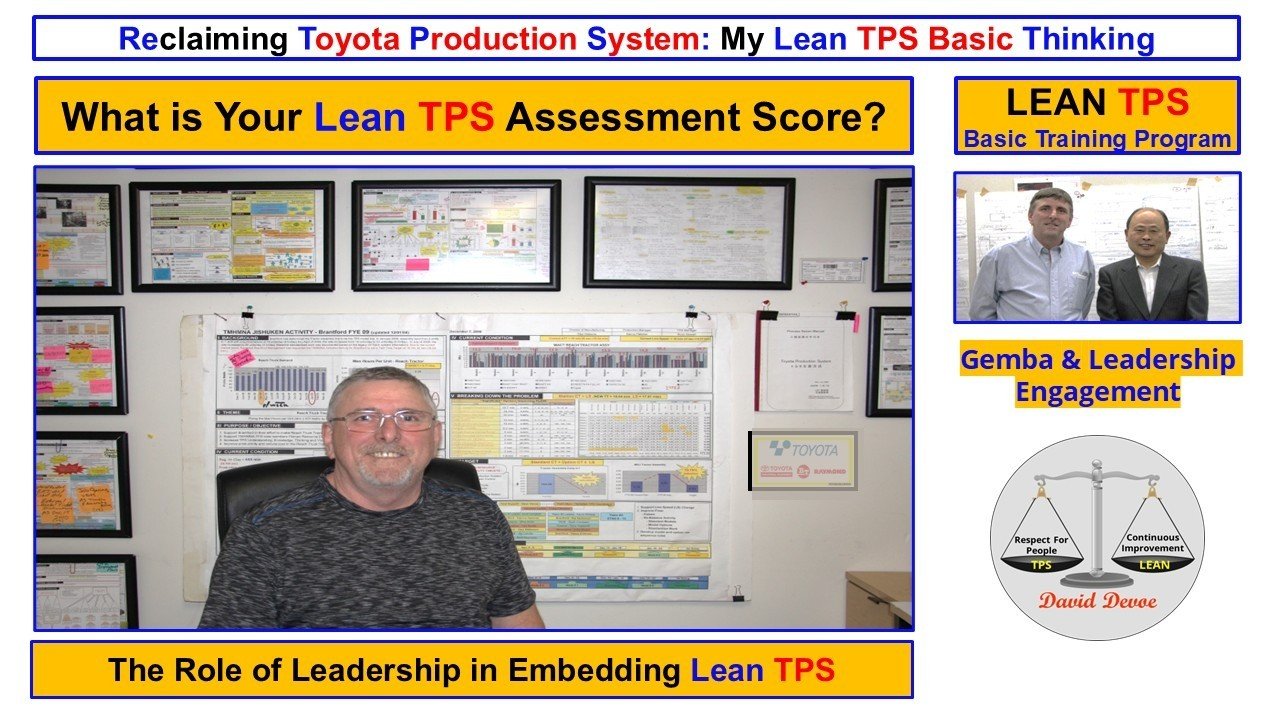

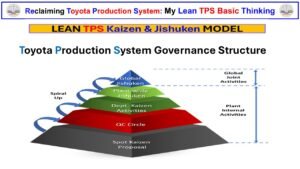

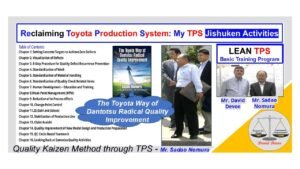

Jishuken Leadership Development

Hands-on improvement cycles that build leadership capability through participation, observation, and accountability at the Gemba.

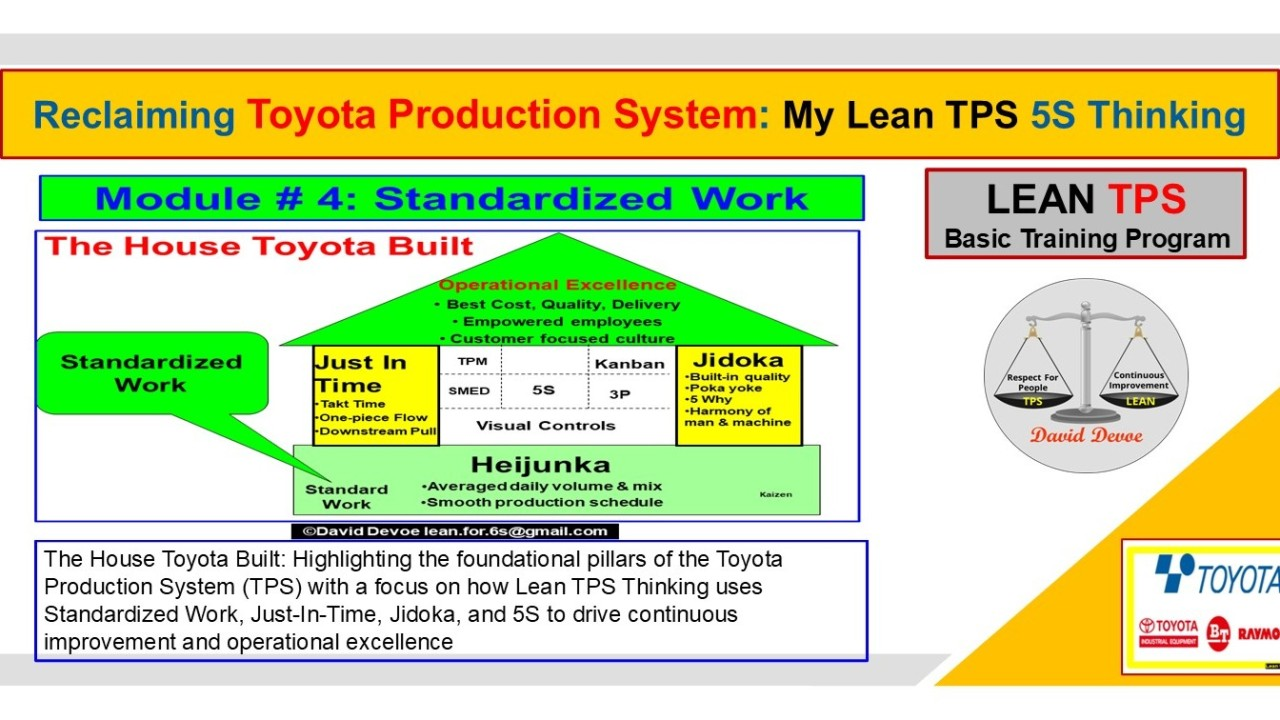

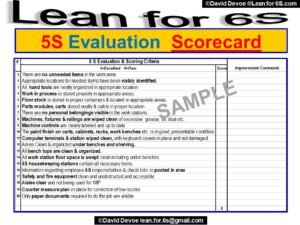

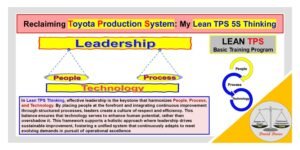

Lean TPS 5S Thinking and Workplace Organization

Establishing structure, visual control, and discipline to protect flow and create the conditions for Kaizen.

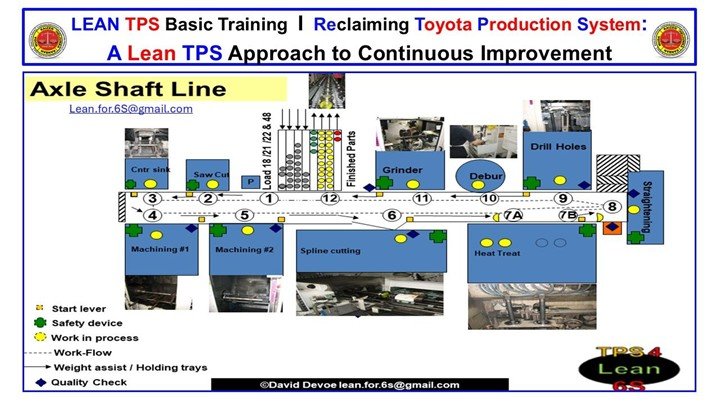

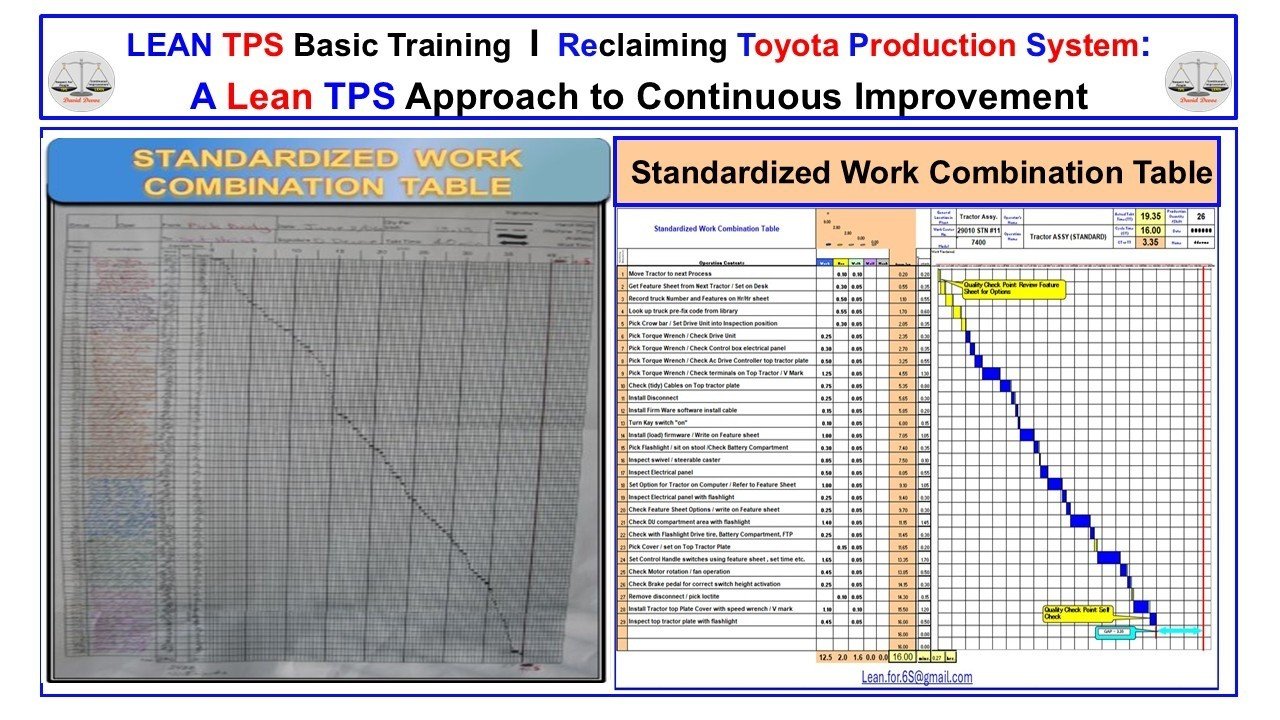

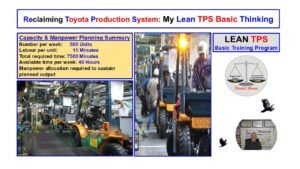

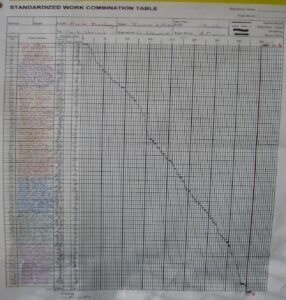

Standardized Work Design and Audit Support

Defining the best known method, connecting people to process, and sustaining improvement through leader observation and verification.

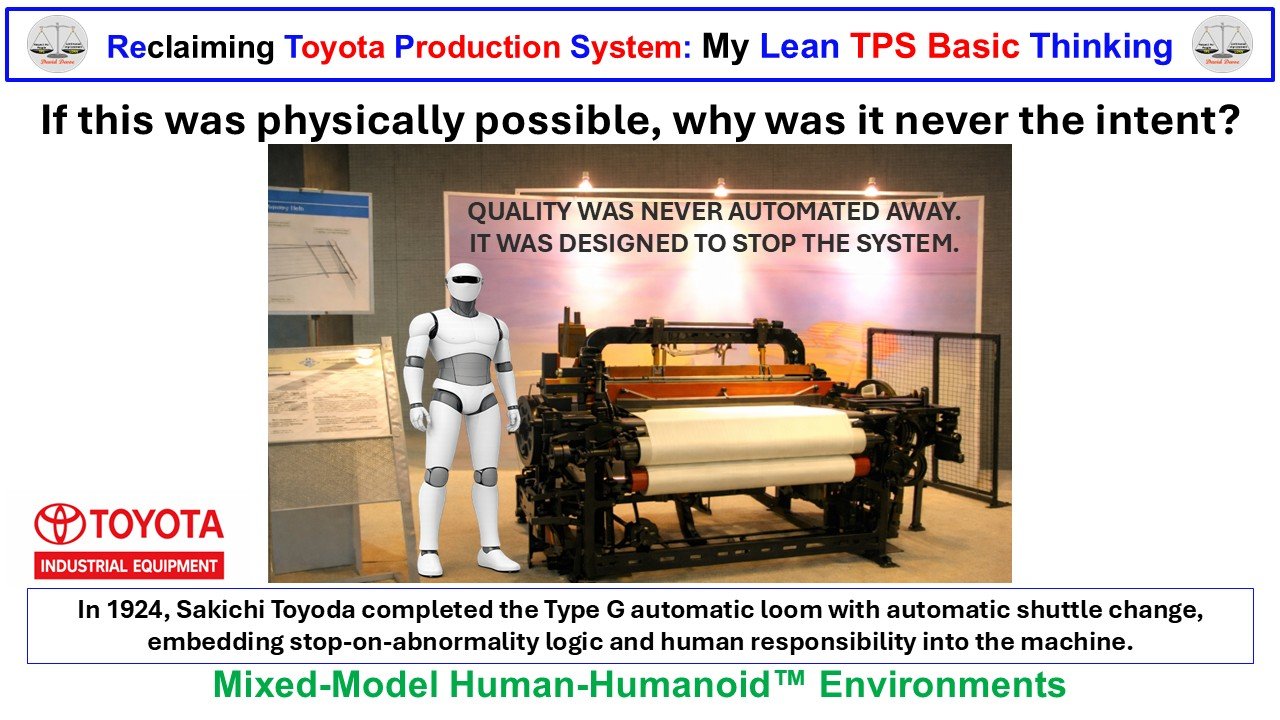

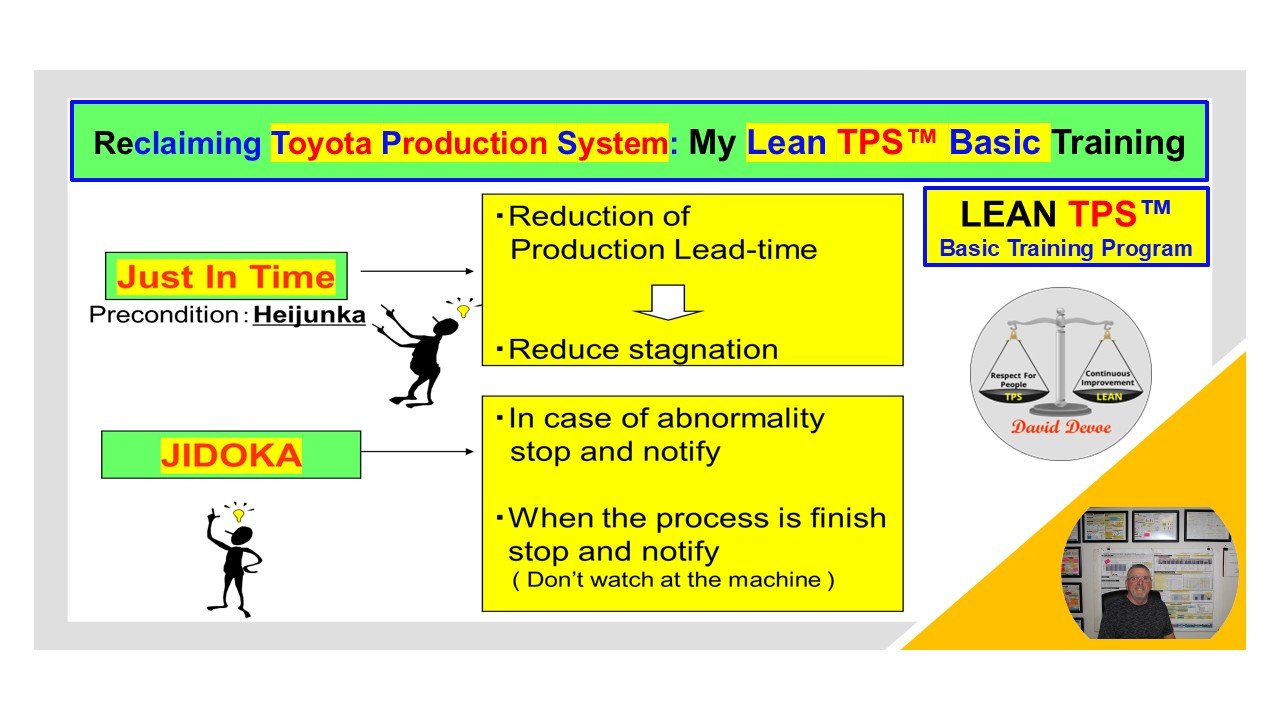

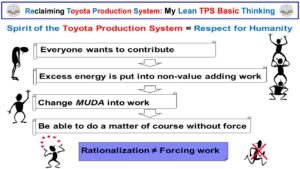

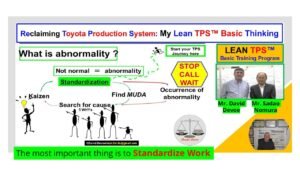

Jidoka and Abnormality Management

Making problems visible through Stop Call Wait, quality response routines, and structured root cause analysis.

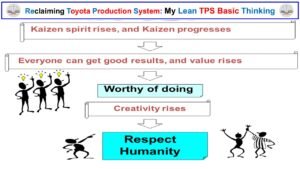

Kaizen Facilitation

Practical improvement activity focused on waste elimination, variation reduction, and sustained flow.