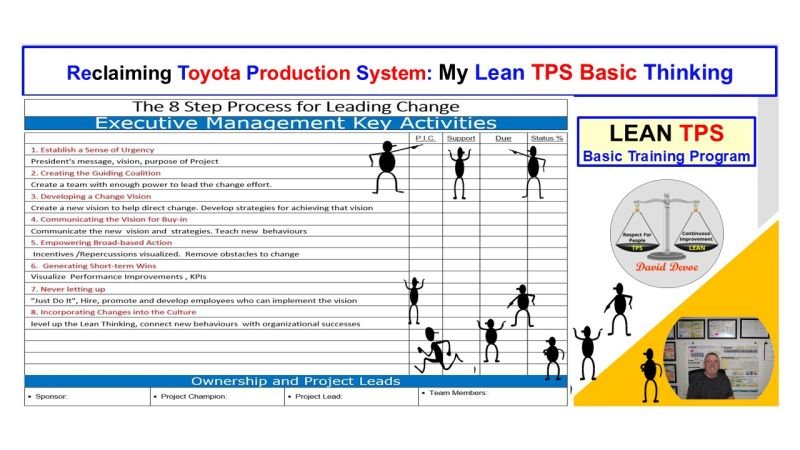

Executive Management Key Activities Guide

Leading change requires structure, discipline, and consistency. In Lean TPS, change is not managed through reaction but through a clear process that connects leadership, communication, and continuous improvement.

The 8-Step Process for Leading Change provides a systematic framework for executive management to plan, execute, and sustain transformation. It is designed to align leadership behavior with organizational goals and ensure improvement becomes part of the daily culture.

1. Establish a Sense of Urgency

Improvement begins when leaders create awareness of the need for change. Urgency is established by identifying risks, clarifying challenges, and communicating the cost of inaction. A clear message supported by data engages teams and motivates action.

2. Create the Guiding Coalition

Sustainable change requires teamwork and authority. Form a guiding coalition of leaders, engineers, and influencers who can remove barriers, share knowledge, and model the desired behaviors. This coalition becomes the driving force behind transformation.

3. Develop a Change Vision

A clear vision directs improvement and defines success. Leadership must articulate where the organization is going, why the change matters, and how progress will be measured. A shared vision provides focus and consistency across all levels.

4. Communicate the Vision for Buy-In

Vision without communication leads to confusion. Leaders must communicate the vision repeatedly, clearly, and visibly. Teaching new behaviors and connecting improvement goals to business results builds trust, engagement, and alignment.

5. Empower Broad-Based Action

Empowerment removes barriers that prevent progress. Provide teams with the tools, training, and authority to take ownership of improvement. Encourage structured problem-solving and accountability so progress becomes self-sustaining.

6. Generate Short-Term Wins

Short-term results validate the process and strengthen commitment. Identify achievable milestones, celebrate progress, and communicate results. Early success creates momentum, reinforces belief, and builds confidence in the new direction.

7. Never Let Up

Improvement is continuous, not event-based. Leaders must sustain attention on the vision, monitor progress, and continue developing capability across all levels. Reinforce the change through coaching, daily review, and consistent application of Lean TPS principles.

8. Incorporate Changes into the Culture

Lasting change requires integration into daily operations. Leaders must embed new practices into standard processes, policies, and management routines. By aligning new behaviors with organizational systems, improvement becomes a permanent part of the culture.

A Framework for Executive Leadership

The 8-Step Process for Leading Change aligns with Toyota’s philosophy of Respect for People and Continuous Improvement. It provides a structure for leadership development, performance alignment, and team engagement.

In Lean TPS Basic Training, this A4-format guide is used to coach executives and project leads on how to:

- Clarify purpose and direction.

- Build effective cross-functional teams.

- Measure progress through visual management.

- Sustain improvement through leadership behavior.

By following this process, organizations create the conditions where improvement is not dependent on individual leaders but embedded into the system itself.