In Toyota, 5S is not a cleaning activity. It is a leadership system that builds the foundation for operational excellence. The purpose of 5S is to create the conditions for flow, discipline, and problem visibility.

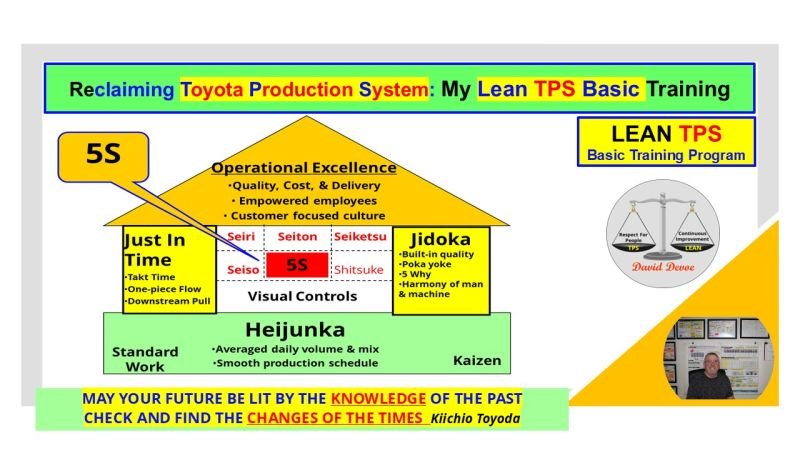

During my TPS training at Toyota, I learned that 5S Thinking is one of the structural pillars of the system. It supports Just-in-Time and Jidoka within the House of Lean TPS. Without 5S Thinking, operational stability and visual control cannot be sustained.

The Role of Leadership in 5S Thinking

5S Thinking is a leadership responsibility. It defines the daily habits that maintain order, flow, and visual control. Leaders must engage directly in 5S activities to ensure standards are understood, applied, and continuously improved.

When 5S is viewed as a management-driven routine, it fails. When it is led as a learning process, it strengthens teamwork and problem-solving at every level.

The 5S steps represent both physical organization and mental discipline:

- Sort (Seiri): Remove what is unnecessary to focus on value.

- Set in Order (Seiton): Place items logically for efficiency and visibility.

- Shine (Seiso): Inspect while cleaning to detect abnormalities.

- Standardize (Seiketsu): Maintain consistency through clear procedures.

- Sustain (Shitsuke): Build discipline so the system becomes self-sustaining.

5S as a Leadership System

At Toyota, 5S was led by supervisors and team leaders, not delegated to others. Leadership defined the standards, participated in Red Tag activities, and followed up through daily observation.

This system taught that improvement starts with visibility. The Red Tag Process ensures that only necessary items remain, waste is identified, and workplace standards are upheld. The process includes:

- Defining what is needed at each workstation.

- Removing and tagging unnecessary items.

- Reviewing and deciding on disposition.

- Auditing to ensure waste does not return.

Leadership plays the central role in verifying that standards are followed, training new members, and encouraging improvement ideas from teams.

The House of Lean TPS and the Role of 5S

In the House Toyota Built, 5S forms the base supporting both Just-in-Time and Jidoka. These two pillars cannot function without standardized conditions.

- Just-in-Time depends on clear flow, consistent locations, and visual control.

- Jidoka depends on the ability to detect abnormalities quickly.

5S provides the structure for both. It stabilizes the environment so that quality, safety, and efficiency can be improved systematically.

Sustaining 5S

The most common failure in 5S implementation occurs when it is treated as an event rather than a system. Sustainability requires:

- Leadership audits that reinforce expectations.

- Training that connects 5S to waste elimination.

- Visual controls that make abnormal conditions visible.

- Team participation that encourages ownership.

At Toyota, 5S was measured not by cleanliness but by the ability to detect and prevent waste. It was a system for seeing problems and sustaining improvements.

Final Reflection

5S Thinking represents the foundation of Lean TPS. It builds structure, visibility, and discipline across every process. Leaders are responsible for embedding 5S as a daily practice that develops people and prevents waste.

When leadership engages fully, 5S becomes a living system that sustains operational excellence and continuous improvement.