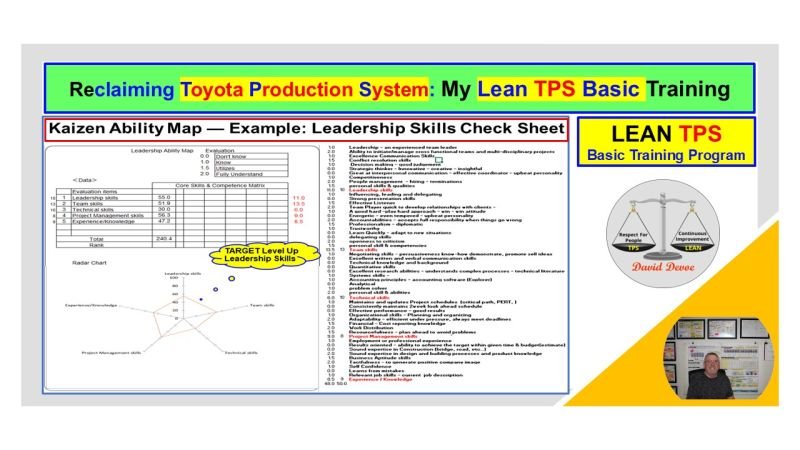

Leadership in Lean TPS is evaluated and developed through structured assessment. The Kaizen Leadership Skills Checklist provides a fact-based method to measure leadership capability, identify gaps, and define improvement targets. It ensures that leadership growth follows the same discipline applied to process improvement.

Purpose of the Leadership Skills Checklist

The Kaizen Leadership Skills Checklist is used within Lean TPS Basic Training to evaluate a leader’s ability to think, communicate, and execute effectively. It aligns leadership development with measurable outcomes rather than subjective impressions.

This structured evaluation produces both quantitative and qualitative feedback. The Radar Chart visualizes performance across five leadership competencies, allowing leaders to focus on areas that most affect team performance and organizational alignment.

Evaluation Criteria

Each competency is scored on a four-level scale to provide consistent evaluation:

- 0.0 – Don’t Know: No knowledge or practical experience.

- 1.0 – Know: Basic awareness with limited application.

- 1.5 – Utilizes: Applies knowledge effectively in daily work.

- 2.0 – Fully Understands: Demonstrates mastery through teaching, coaching, and leadership.

Scores are collected across multiple categories, generating a balanced picture of leadership performance.

Assessment Results

Leadership Skills – Score: 55

Strong performance in decision-making, communication, and strategic execution. Improvement is needed in coaching and motivation to build stronger engagement and team capability.

Team Skills – Score: 52

Demonstrated ability in collaboration and negotiation. Additional development in technical coordination and structured problem-solving will increase team effectiveness.

Technical Skills – Score: 30

Lowest performance area, indicating a need for stronger process knowledge and analytical ability. Leaders should enhance their understanding of production systems, reporting, and data-driven decision-making.

Project Management Skills – Score: 56

Highest performing category, showing strong ability to plan, schedule, and manage resources. Further growth in contingency planning and risk management will reinforce consistency.

Experience and Knowledge – Score: 47

Solid understanding of business fundamentals and continuous learning. Leaders should deepen specialized expertise and broaden exposure to different work environments to enhance adaptability.

Radar Chart and Development Focus

The Radar Chart provides a visual summary of strengths and improvement areas. Leadership and Project Management scores form the outer edge of the chart, indicating strength in execution. Technical Skills form the narrowest band, showing the greatest opportunity for improvement.

This visual method reinforces Lean TPS principles: make problems visible, define root causes, and apply countermeasures. The Kaizen approach ensures that leadership development follows a PDCA cycle rather than relying on occasional reviews.

Application in Lean TPS Leadership Training

In Lean TPS, leadership development is treated as a process to be improved. The Leadership Skills Checklist is integrated into training modules and Jishuken activities, where leaders assess, plan, and act on their own development needs.

Through this process, leaders learn to:

- Evaluate their own performance objectively.

- Identify improvement priorities through data.

- Plan countermeasures using the A3 problem-solving structure.

- Implement actions and verify progress through Genchi Genbutsu.

- Share learning through Yokoten to build collective capability.

Continuous Improvement in Leadership

Leadership growth within Lean TPS mirrors the same discipline applied to quality and production. It is continuous, structured, and measurable. The Leadership Skills Checklist transforms leadership from intuition into a process of learning and refinement.

By focusing on skill development, structured evaluation, and coaching, Lean TPS ensures that leadership improvement drives organizational stability, capability, and engagement.