Ottawa’s business community is positioned for growth across manufacturing, logistics, technology, and service industries. The challenge is not opportunity, but structure. Many organizations operate with potential that is limited by inefficiency, poor communication, and reactive decision-making.

Toyota’s Production System (TPS) is more than a manufacturing method. It is a leadership system that builds capability, eliminates waste, and creates lasting value. Its strength lies in its structure: developing people, designing processes, and establishing systems that prevent problems before they occur.

A Proven Framework for Sustainable Growth

At Toyota, every improvement begins with a clear purpose. The goal is not short-term gain but long-term stability and customer trust. TPS builds this stability by focusing on:

- Eliminating waste at its source through daily observation and problem-solving.

- Standardizing work to ensure consistency and predictability.

- Engaging employees to take ownership of quality and improvement.

- Developing leaders who understand both the technical and human side of improvement.

This system transforms organizations from reactive to proactive. It strengthens quality, reduces cost, and enhances customer responsiveness through structured improvement.

My Journey with Toyota Production System

During my career with Toyota Industries Corporation (TICO) and The Raymond Corporation, I was selected for an intensive three-month immersion program at Toyota L&F in Takahama, Japan. This facility remains one of the world’s most advanced high-mix, small-lot production sites—where TPS is practiced and refined daily.

The experience was not classroom training. It was direct engagement at the Gemba, working with senior Toyota leaders to solve real operational challenges. I learned that true TPS cannot be copied or simplified into a set of tools. It must be lived and practiced.

When I returned to North America, I was appointed to lead the rollout of TPS at Toyota’s Canadian operations. Later, I joined the Toyota Material Handling Manufacturing North America (TMHMNA) TPS Working Group, where we aligned improvement practices across multiple plants in the United States, Canada, and Japan.

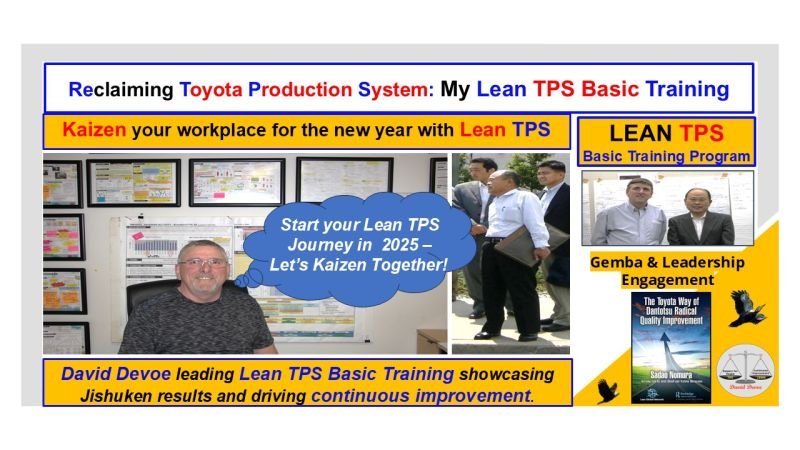

Building Lean TPS Basic Training

Based on my experience at Toyota, I developed the Lean TPS Basic Training Program a structured system that preserves Toyota’s original methods while adapting them to different industries and cultures.

The training combines:

- Genchi Genbutsu (Go See) – Learning directly from the workplace, not from reports.

- Kaizen and Jishuken – Structured problem-solving and leadership participation.

- Built-in Quality and Standardized Work – Establishing stability and flow.

- Leadership Development – Teaching leaders how to think and act through TPS.

This approach ensures that organizations build internal capability rather than relying on external consultants. It helps teams think systematically, act decisively, and sustain improvement over time.

How TPS Applies Beyond Manufacturing

The principles of the Toyota Production System are universal. They apply to any process where value must be delivered efficiently and reliably.

- Manufacturing and Logistics: Reduce waste, optimize flow, and strengthen quality control.

- Service Industries: Use Standardized Work and problem-solving to improve customer experience.

- Technology and Startups: Apply Just in Time and Jidoka thinking to manage growth and complexity.

The system adapts across industries because its foundation is not tools, but people. TPS is a way of developing organizations that can improve themselves continuously.

The Ottawa Opportunity

Ottawa has the talent, innovation, and diversity to lead in operational excellence. What is needed is structure the same disciplined framework that made Toyota a global benchmark.

Through Lean TPS Basic Training and structured improvement coaching, organizations in Ottawa can:

- Build leadership capability through daily problem-solving.

- Reduce waste and variation across operations.

- Strengthen communication and cross-functional teamwork.

- Develop resilient systems that sustain growth through change.

Moving Forward

My work is focused on helping Ottawa organizations apply authentic Toyota methods to achieve lasting improvement. The approach is practical, proven, and grounded in real experience at Toyota.

If your business is ready to strengthen performance through structure, leadership, and continuous improvement, I welcome the opportunity to collaborate.

TPS is not just a system for factories. It is a system for thinking one that transforms how organizations grow, adapt, and lead.