A disciplined and efficient workplace is not achieved through one-time initiatives. It is sustained through the final two pillars of 5S Thinking: Standardize and Sustain. These principles ensure that improvements are embedded into daily work rather than fading over time.

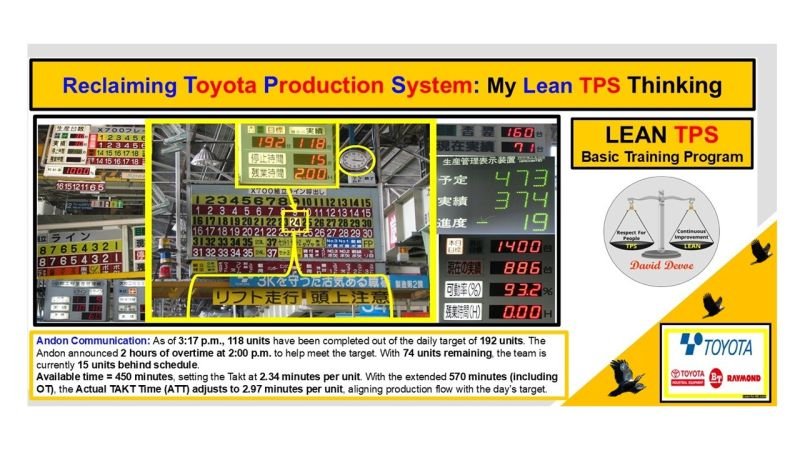

At Toyota, visual management tools such as Andon Communication Boards make these principles visible. They display real-time production performance, connecting leadership, teams, and processes through standardized feedback. Every number, color, and light on an Andon Board reflects the condition of the system, allowing immediate action and shared awareness.

Why Visual Management is Essential

A production floor without standardized communication operates reactively. Andon Boards prevent this by displaying live production data such as actual performance, target units, downtime, and takt time adjustments. This visibility ensures that problems are identified at the source and addressed immediately.

At Toyota BT Raymond, the implementation of Standardize and Sustain within 5S transformed operations. Structured checklists, visual cues, and clearly defined standards replaced informal communication and guesswork. The result was greater process stability, reduced waste, and improved workflow consistency. Teams could see their progress and respond quickly to deviations from plan.

Visual management does more than share data. It reinforces accountability. When progress is transparent, leadership can focus on problem-solving instead of inspection. This creates a learning environment where teams understand the relationship between performance, standards, and improvement.

Embedding Standardization into Culture

For Lean TPS 5S Thinking to succeed, Standardization must exist across all areas, shifts, and roles. Without shared standards, improvement collapses into inconsistency. The 5S Evaluation and Scoring System provides structure for this discipline. Using 20 evaluation criteria scored on a five-point scale, it allows leaders to measure performance, identify trends, and prioritize improvements.

Standardization connects every level of the organization. It defines expectations for workplace organization, cleanliness, equipment checks, and safety routines. More importantly, it provides a baseline for improvement. Once standards are visible and measurable, teams can focus on refining them through Kaizen and daily problem-solving.

Sustaining 5S Thinking for Long-Term Success

Sustainment is where transformation becomes permanent. It is achieved through repetition, reflection, and reinforcement. In Lean TPS, sustainability depends on leadership commitment and team participation. The following practices maintain 5S performance over time:

- Regular 5S Audits ensure consistency and accountability.

- Visual Controls keep standards visible and reduce ambiguity.

- Team Ownership reinforces pride and responsibility in maintaining improvements.

Andon Communication Boards play a direct role in sustaining 5S Thinking. Real-time visibility allows immediate response to performance issues, supports continuous monitoring, and reinforces the link between process control and improvement. These feedback loops build the discipline required for long-term operational stability.

Final Thought

Standardization and Sustainment are not the conclusion of 5S; they are the beginning of a learning cycle that strengthens over time. Visual management, through tools like Andon, enables people to see, act, and improve. When teams use structured feedback to reinforce standards, Lean TPS principles become part of the culture. Sustainable improvement is not about compliance. It is about creating systems where people continuously maintain and advance excellence.