Change is inevitable, but leadership determines whether it leads to progress or resistance. Within the Toyota Production System, successful change is built on structure, communication, and respect for people. Change must be guided, not forced. It requires leadership that builds commitment, develops capability, and manages transitions effectively.

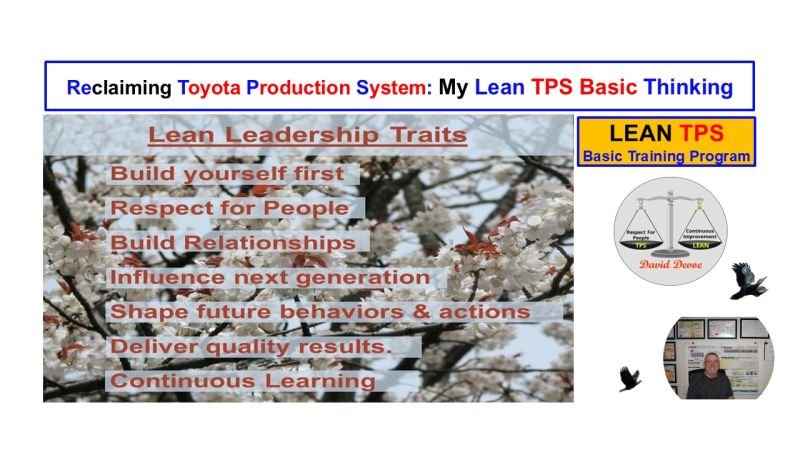

One of the most valuable lessons from Toyota is that leadership is not just decision-making. It is the ability to shape behaviors, build relationships, and influence the next generation. Leaders who develop these skills create sustainable improvement rather than temporary compliance.

The Role of Leadership in Driving Change

Build Yourself First

Leaders must develop adaptability before expecting others to change. Personal reflection, study, and discipline are the foundation of leadership credibility.

Respect for People

Change begins with trust. People must understand why change is necessary and how it benefits them and the organization. Without mutual respect, improvement cannot take root.

Build Commitment Across Groups

Change succeeds when teams, departments, suppliers, and leadership share alignment. Commitment requires shared objectives, not individual agendas.

Manage the Emotional Impact of Change

Every change introduces uncertainty. People often experience loss before recognizing benefits. Leaders must guide their teams through discomfort before expecting full engagement.

Shape Future Behaviors and Actions

Change must be reinforced through leadership behavior. Leaders who model accountability, consistency, and follow-up set the standard for others to follow.

Structured Implementation and Quality Checks

Lean TPS emphasizes structure through PDCA, A3 problem-solving, and Change Point Management. These tools ensure transitions are tested, verified, and standardized before full adoption.

Closing the Change Gap

Leaders often assume people are ready for change, but readiness depends on communication and timing. Early involvement reduces resistance and prevents misunderstanding. When employees participate in planning, the change gap narrows and ownership increases.

Sustaining Change Requires Leadership Presence

Change does not end at implementation. Leaders must remain visible and involved to ensure new standards are maintained. When leadership attention fades, so does commitment. Sustaining change requires consistent review, recognition, and correction.

How Leadership Traits Influence Change Success

Leaders influence the success of change through their actions and habits. Building relationships creates trust, and trust accelerates improvement. Influencing the next generation ensures that leadership behaviors, not just systems, are passed forward. Continuous learning keeps leaders adaptable, ensuring they can guide teams through complex and changing conditions.

At Toyota, leadership is measured not by authority but by the ability to teach and sustain improvement. Each leader’s responsibility is to develop others while maintaining system stability. The connection between leadership and change lies in building capability rather than enforcing compliance.

Final Thoughts

Change is a constant condition of progress. It cannot be delegated or outsourced. At Toyota, change is led through structure, respect, and presence. Lean TPS provides the framework, but leadership gives it life. Leaders who build relationships, demonstrate respect, and stay engaged after implementation create lasting results.

True leadership prepares people to improve, not just to adapt. The organization that learns to manage change through its leaders will always stay ahead of the times.