5S is often misunderstood as a workplace organization tool. At Toyota, it is much more than that. It is the foundation of stability, the entry point to continuous improvement, and the visual expression of a disciplined culture.

In Lean TPS, 5S Thinking is not about cleaning or inspection checklists. It is a behavioral system that shapes how people interact with their environment, identify abnormalities, and sustain standards. It builds the foundation for flow, quality, and teamwork. Without 5S, Lean TPS cannot take root because instability and disorder prevent problems from being seen.

5S as the Foundation of the System

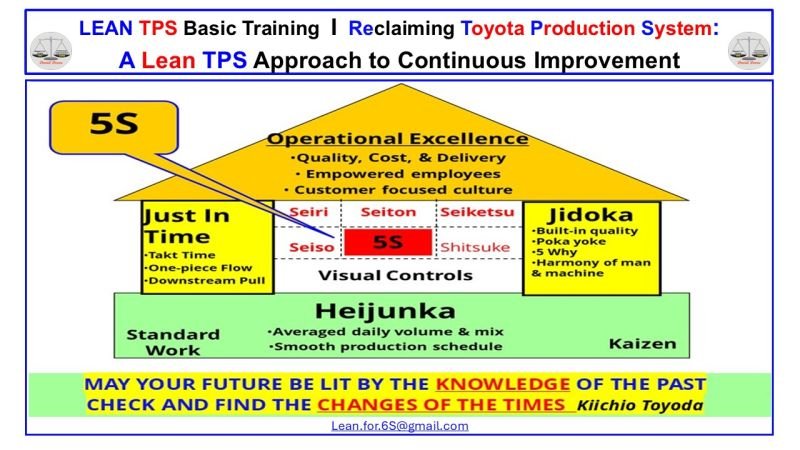

The 5S structure sits at the base of the Toyota Production System, supporting Just-In-Time, Jidoka, Heijunka, and Kaizen. These pillars cannot function without stability. 5S creates that stability by building discipline and visual awareness into daily work.

In my Lean TPS approach, 5S Thinking connects people, process, and leadership. It teaches how to see waste, how to think through problems, and how to act with structure. It transforms improvement from an abstract goal into a visible, shared practice.

The five steps of 5S Thinking form a sequence of behavior that develops both people and systems:

- Sort (Seiri): Remove what is unnecessary. Keep only what supports the work. This creates space, order, and clarity.

- Set in Order (Seiton): Define where everything belongs. Tools, materials, and information should be positioned for flow, not convenience.

- Shine (Seiso): Clean to inspect. Cleaning is a form of checking that ensures readiness and exposes early signs of wear, damage, or abnormal conditions.

- Standardize (Seiketsu): Establish consistent methods and visual controls to maintain the first three S’s. This converts effort into structure.

- Sustain (Shitsuke): Build habits through leadership example and confirmation. Sustainment requires leaders to model the behavior daily.

Each step builds the discipline that makes improvement possible.

The Role of Leadership

At Toyota, 5S was never assigned to junior staff or treated as a side activity. It was led by supervisors, engineers, and managers who used it to strengthen process understanding and coach problem-solving. Leadership involvement gave meaning to the activity. It was not about appearance. It was about control through visibility.

Leaders were expected to participate directly in 5S checks and teach through action. The goal was not to score performance, but to reinforce the link between physical order and mental readiness. 5S is a leadership behavior that turns intention into system design.

5S Thinking Across Environments

The same principles apply whether the work is done in manufacturing, logistics, infrastructure, or office settings. In every environment, 5S exposes waste, builds ownership, and clarifies flow. It shows how people relate to their work and how management supports them.

When applied correctly, 5S Thinking supports the full Lean TPS framework:

- Just-In-Time: Visual organization reveals shortages, excess, and timing gaps.

- Jidoka: Clean and visible conditions expose defects and prevent recurrence.

- Heijunka: Balanced and standardized routines reduce workload variation.

- Kaizen: Continuous improvement begins once the standard is clear and visible.

Building the Culture of Improvement

5S Thinking is not the end of Lean TPS. It is the beginning. It establishes the habits that allow the system to work as one. When practiced consistently, it cultivates pride, discipline, and awareness across all levels of the organization.

As Kiichiro Toyoda advised, “May your future be lit by the knowledge of the past. Check and find the changes of the times.” 5S embodies this principle by connecting what we have learned to how we improve today. It is the bridge between past experience and future readiness.

If your organization struggles with hidden waste, instability, or disconnected leadership, start with 5S. But practice it as a thinking system, not a checklist. It is how Lean TPS begins and how improvement becomes a daily habit.