Every Lean TPS journey begins with learning to see waste. Once waste becomes visible, the focus of improvement shifts. Teams stop fixing symptoms and start redesigning systems. Leaders stop chasing efficiency and begin building long-term capability.

During my Lean TPS training in Japan, we did not start with tools or metrics. We started with mindset. The first lesson was to see Muda. Toyota teaches seven traditional types of waste, but we also learned an eighth: the waste of underutilized people. This waste is not about blaming individuals. It is about recognizing when the system fails to use their potential. When that happens, the process cannot improve.

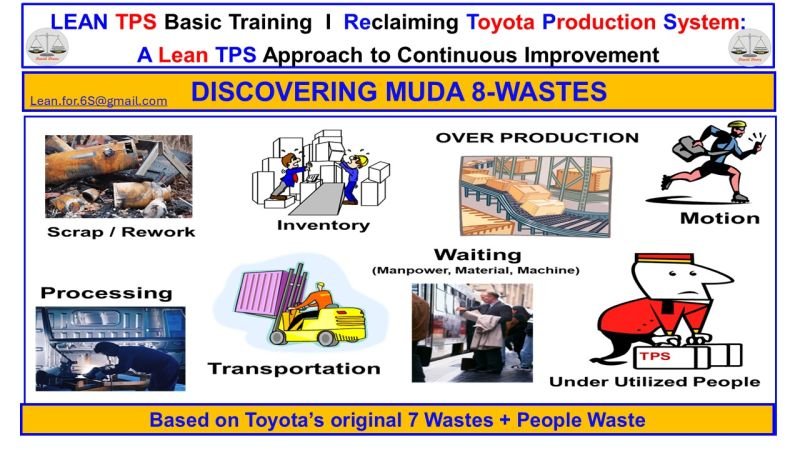

The 8 Wastes of Lean TPS

1. Overproduction

Producing more than needed or producing too early hides problems and creates excess. It disrupts flow and increases cost.

2. Inventory

Stockpiling material, parts, or information hides instability. It increases lead time and prevents problems from surfacing.

3. Waiting

Idle time caused by unbalanced work, missing parts, or delayed machines. Waiting time is often greater than anyone realizes.

4. Motion

Unnecessary movement of people due to poor layout, unclear standards, or missing tools. Motion waste creates fatigue and inconsistency.

5. Transportation

Extra movement of materials or information between locations. It adds cost without adding value and signals broken flow.

6. Processing

Steps that do not add value from the customer’s perspective. Often built into legacy systems or unchecked procedures.

7. Defects and Rework

Errors that require correction or scrap. Each one exposes a gap in Standardized Work, training, or process design.

8. Underutilized People

The most critical waste. It occurs when the system does not support people to use their skill, knowledge, or creativity. This waste limits improvement and weakens culture.

Why Seeing Waste Comes First

Seeing waste is the foundation of improvement. It teaches how to see the system rather than just the output. It creates new questions that expose hidden loss:

Why do we do it this way?

Why is this still accepted?

What is preventing better flow?

The ability to see clearly is what separates Lean TPS from tool-based programs. Once people can see, they can learn to act with purpose. That is when 5S Thinking, Standardized Work, and Kaizen routines become effective.

The Practical Starting Point

This 8 Wastes visual is part of Lean TPS Basic Training. It helps teams identify where value is lost and start meaningful discussions at the Gemba. Many organizations begin improvement with metrics or templates. Toyota begins with people. When people learn to see, they can improve. When structure supports them, improvement holds.

For organizations beginning a Lean TPS transformation, this is where to start. Make waste visible. Discuss it. Link it to real flow. From there, the path to Just-in-Time, Jidoka, and Heijunka becomes clear.