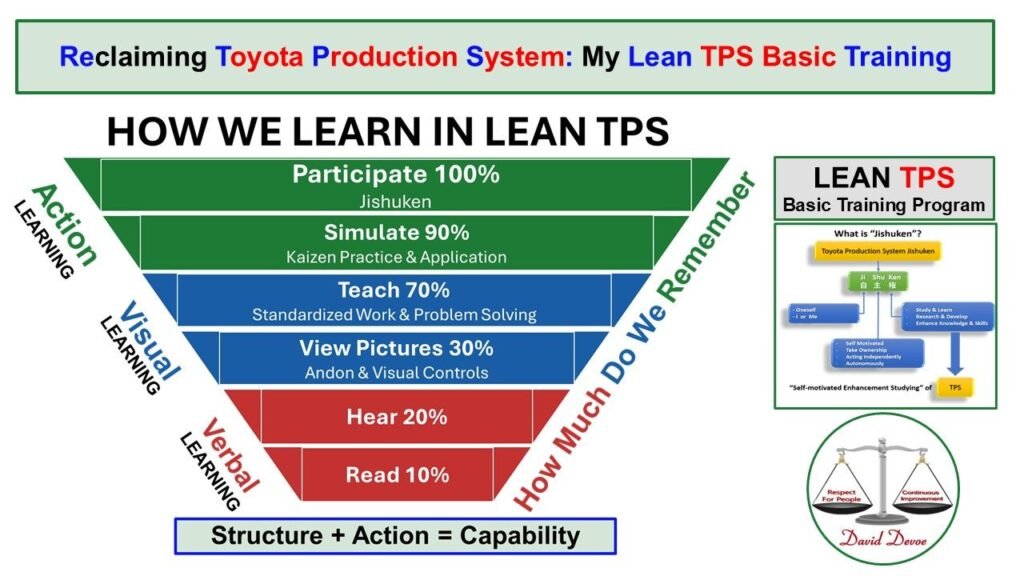

Many organizations think training means PowerPoints, lectures, and policies. The way people actually learn is very different. Reading gives little retention. Hearing adds a small amount. Pictures and videos help, but not enough. Real learning happens when people act, simulate, teach, and take ownership at the workplace.

This is why Lean TPS Basic Training begins with action learning. Participation is part of the structure. People remember because they practice, simulate, teach, and connect directly with the work. Lean TPS builds capability through structure and disciplined practice, not awareness alone.

At the top of the learning funnel is Participate 100%. This is Jishuken, meaning self-motivated study and ownership of improvement. Leaders and teams take responsibility for structured learning, research, and development through direct action. Jishuken represents the highest form of learning in Lean TPS because it develops accountability and respect for people.

Next is Simulate 90%. This is Kaizen practice and application. Teams conduct structured experiments, test countermeasures, and confirm cause and effect. Simulation transforms abstract ideas into practical understanding and builds confidence in problem-solving.

Next is Teach 70%. In Lean TPS, teaching means demonstrating Standardized Work and coaching others in problem-solving. It is supported by A3 Thinking, 5 Whys, and confirmation checks. Teaching reinforces learning and turns understanding into shared capability.

The fourth stage is View Pictures 30%. Visual learning through Andon, charts, and control boards makes problems visible and guides action at the Gemba.

At the lower levels are Hear 20% and Read 10%. These methods create awareness but not sustained skill. Without structure and repetition, awareness fades and improvement efforts collapse.

On the right side of the funnel is the definition of Jishuken. It is self-motivated enhancement study. It is not a slogan but a structured system of leadership-driven learning that distinguishes Lean TPS from compliance or certification programs.

The funnel closes with the principle: Structure + Action = Capability.

Without structure, learning is scattered. Without action, learning is temporary. When both are present, organizations build capability that endures and strengthens over time.

This is why Lean TPS training begins with 5S, Kaizen, and Jishuken. These practices teach by participation, simulation, and instruction at the Gemba. Lean TPS is not about memorizing slides. It is about developing real capability through structured learning by doing.