Inside Toyota, Stop Call Wait is the daily practice that turns Jidoka from concept into discipline. It is a system that makes quality everyone’s responsibility by combining structure, leadership, and respect.

When an operator detects an abnormality, the steps are clear and non-negotiable: stop the process, call the team leader, and wait for direction. The leader’s role is to respond immediately, confirm the situation, and decide the next action. This is the Andon system in motion, where the signal is not a light or cord, but the call that brings leadership directly to the Gemba.

This structure gives responsibility to the operator and accountability to the leader. It builds quality into the process rather than inspecting it afterward. Problems are surfaced immediately in front of the people who can act. Operators are never punished for stopping. Leaders are expected to stand in the problem, make a decision, and support the team. The failure of one process becomes a learning point for all.

This is why Toyota calls it Blame-Free Jidoka. The problem belongs to the system, not the person.

Stop Call Wait at the Gemba

During my Jishuken training at Toyota L&F in Takahama, Japan, I saw Stop Call Wait practiced as part of daily leadership development. When an abnormality occurred, the line stopped, and leaders came immediately to confirm the condition. No discussion happened away from the work. The facts were visible where the problem occurred.

The team did not restart until a countermeasure was agreed upon. Sometimes the leader decided to continue with close monitoring; other times, the work was adjusted or stopped completely. Each decision was based on fact, not hierarchy. The rule was simple: do not hide a problem. Make it visible and act.

The Prerequisite: Standardized Work

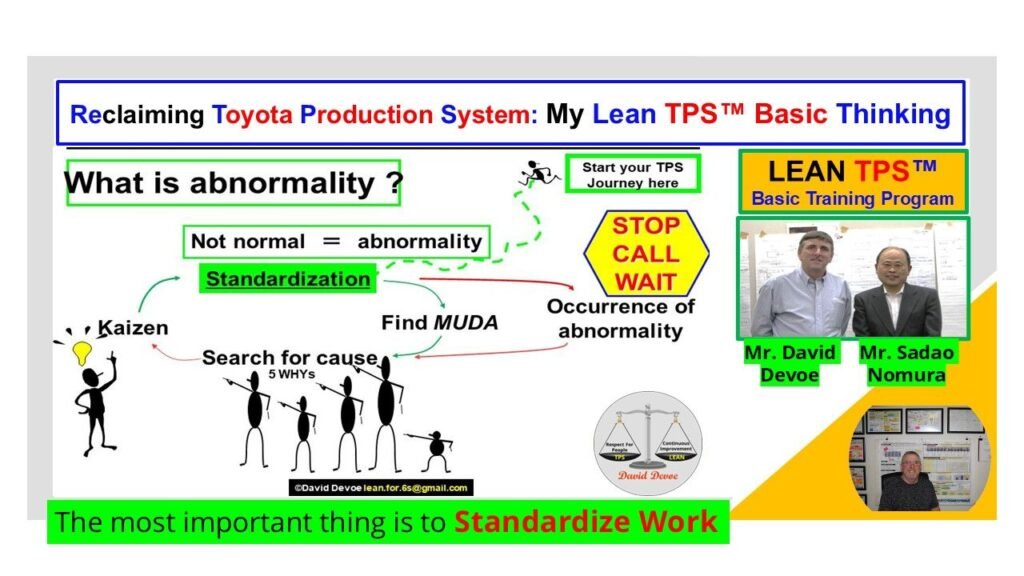

Stop Call Wait only functions when Standardized Work is in place. Without standards, there is no way to see normal from abnormal. At Toyota, the three elements of Standardized Work are always present: takt time, work sequence, and standard work in process. These define what normal looks like. Any deviation becomes instantly visible.

When an operator calls, it is not a sign of weakness. It is proof that the system is functioning. The call exposes variation before it turns into waste or defect. Leadership response closes the loop.

Once stability is restored, root cause problem solving begins. Leaders and operators apply the 5 Whys to understand the cause and confirm the countermeasure. Kaizen follows, building capability and confidence. Each solved abnormality becomes the baseline for the next improvement.

The Structure of Respect

Stop Call Wait reflects Toyota’s belief that structure is the highest form of respect for people. It protects the operator by giving authority to stop. It demands accountability from leaders to respond. It prevents rework and protects the customer.

Too many organizations confuse quality with awareness. Posters and slogans cannot prevent defects. Structure prevents defects. Stop Call Wait is that structure. It makes problems visible, brings leaders to the Gemba, and teaches teams that improvement begins when the process stops.

At its core, Stop Call Wait is not an operator habit. It is a leadership discipline that defines how responsibility and accountability function together. It is the living expression of Respect for People and Continuous Improvement.