A disorganized workplace is more than an operational problem. It is a sign of deeper systemic failure in leadership, discipline, and respect. When tools are scattered, pathways are blocked, and equipment has no defined home, workers are forced to struggle against their environment. This condition creates wasted motion, safety hazards, and frustration that erodes performance.

At Toyota BT Raymond, the absence of structure in one production area exposed these issues. Workers spent time searching for tools and navigating cluttered spaces. Efficiency and safety were compromised. Through the application of Lean TPS 5S Thinking, the same workspace was transformed into a model of order, safety, and stability.

From Disorder to Discipline

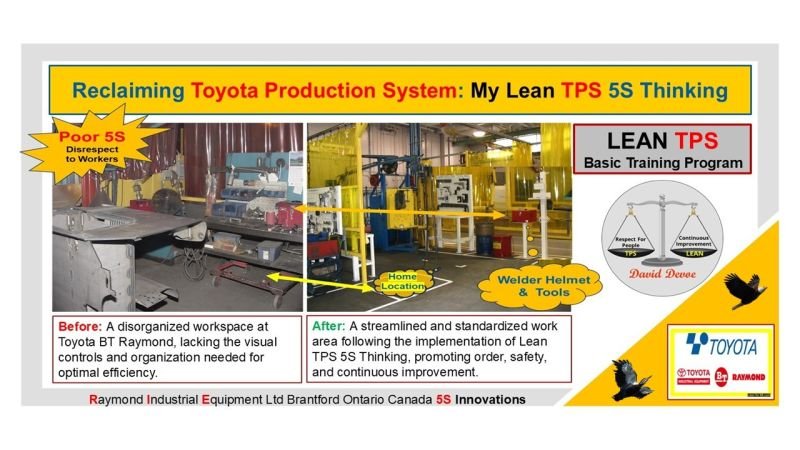

The before image shows a chaotic, unstructured workspace. Tools and materials are scattered without logic or purpose. No visual controls exist to guide placement or flow. Workers adapt individually rather than operating through a shared standard. Time is lost to searching and repositioning, and safety risks increase through unmanaged clutter.

The after image reveals the effect of disciplined 5S Thinking. Tools and materials have defined home locations. Work areas are clearly marked and visually organized. Flow is improved, and every movement supports value-added activity. This transformation demonstrates that 5S is not about housekeeping. It is a method for restoring stability and respect by creating a workplace that supports people and process.

How Lean TPS 5S Thinking Strengthens Workplace Transformation

- Visual Controls Implemented: Clear markings identify tool locations and storage zones, eliminating confusion.

- Work Area Standardization: Defined walkways and work zones reduce wasted motion and improve safety.

- Improved Safety Measures: Hazards are eliminated through organized layout and visibility.

- Increased Efficiency: Reduced searching time allows workers to focus on value creation.

These principles go beyond visual order. They form the behavioral foundation for continuous improvement. When every person understands and maintains standards, performance becomes predictable and improvement becomes sustainable.

5S as a Reflection of Respect for People

A poor 5S environment is a sign of disrespect. It forces people to compensate for poor systems, creating fatigue and inefficiency. When 5S is properly applied, it provides the conditions for focus, quality, and pride in work. It allows employees to contribute improvement ideas rather than struggle against disorder.

In Lean TPS, respect for people is not symbolic. It is expressed through design. Every visual control, standard, and location mark reflects leadership’s commitment to making work easier, safer, and more efficient.

Final Thought

This transformation at Toyota BT Raymond illustrates the power of Lean TPS 5S Thinking as both a technical and human system. Order and efficiency are achieved not through tools alone but through leadership discipline and respect. When 5S becomes daily practice, workplaces move beyond compliance toward a culture where people, process, and safety reinforce one another.