When many organizations think of 5S, they imagine cleaning days, fresh paint, and neatly arranged tool racks. While those actions improve appearance, they miss the true purpose of 5S in Lean TPS. The goal is not visual order for its own sake. The goal is to build a stable, repeatable environment that supports flow, reduces waste, and develops capability.

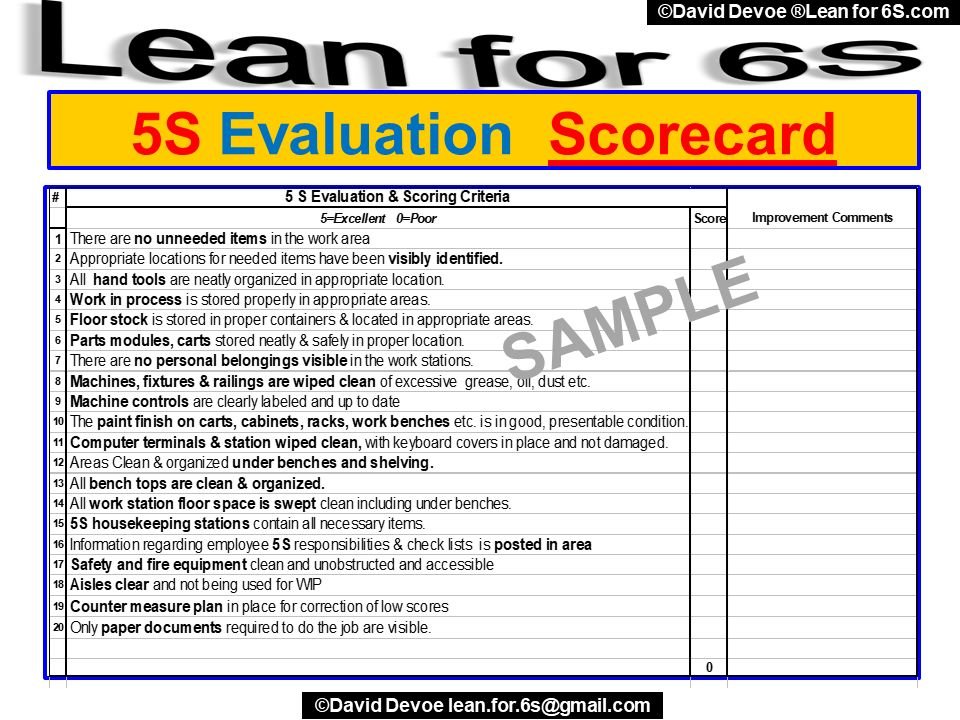

The 5S Evaluation Scorecard was designed for that purpose. It is not a tool for high scores or presentation. It is a visual standard that defines how safety, organization, and readiness are maintained at the Gemba.

Each line on the scorecard connects directly to performance:

- Removing unneeded items frees space and reduces motion waste.

- Defining locations ensures that anyone can find and return tools quickly.

- Cleaning machines prevents defects and extends equipment life.

- Documented countermeasures ensure that problems are acted upon, not hidden.

In Lean TPS, 5S is not evaluated on appearance but on function. A workstation may look clean, yet still fail if safety equipment is blocked, work in process is scattered, or documentation is missing. The scorecard makes this visible. It sets the baseline for stability and improvement.

Using the scorecard, leaders can measure consistency, identify patterns, and act early. It trains them to see deviations before they become breakdowns. That is how risk is prevented rather than managed after the fact.

A high-functioning 5S system within Lean TPS always includes:

- A clear, visual standard for each area.

- A consistent scoring method and frequency.

- A defined review rhythm linked to leader standard work.

- Countermeasures recorded and verified after every evaluation.

5S is not a short-term project. It is a discipline that must be practiced daily. The 5S Evaluation Scorecard keeps the focus on what matters most: safety, quality, delivery, and cost performance through a stable, well-organized workplace.

If 5S in your organization feels like housekeeping, the scorecard will help reveal its true purpose. It is the structure that connects discipline to daily performance and turns visual order into sustained improvement.